47

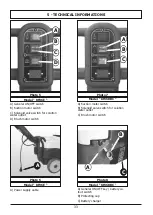

8.8 THERMAL BREAKERS

The machine is equipped with electric protection

devices on the main operating components to avoid

costly malfunctions.

Thermal breakers are installed to protect the suc-

tion motor ( Photo 16 - C ) wherever foreseen and

the brush motor ( Photo 16 - D ).

When one of these breakers trips automatically, the

disabled function can be reactivated by fully de-

pressing the button of the breaker.

When the thermal breakers trip, especially when

the machine is used during the first few weeks, it

might not be caused by actual machine malfunc-

tions. However, a specialized technician should

check the device if the relative breaker continues

to trip.

8.9 PERIODIC MAINTENANCE

For all the operations described herein, refer to the

instructions and detailed warnings in the relative

sections.

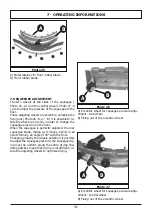

8.9.1 DAILY OPERATIONS

Disassemble and check the brush or the pad driver

disk (with the abrasive pad assembled).

Check that there are no foreign bodies that may im-

pede the movement or efficiency of all cleaning

parts.

Check the squeegee: clean the blades and check

their condition/wear.

If Pb-Acid batteries are used, carefully carry out the

operations described by the battery manufacturer.

Charge the batteries.

8.9.2 WEEKLY OPERATIONS

Check and, if necessary, replace the splash guard.

Carefully check the profile of the squeegee blades

and replace them, if necessary.

Check that the suction hoses and conduits are not

clogged;

Thoroughly clean the solution and recovery tanks.

For other models with the Pb-Acid battery: check

the level of the electrolyte in all elements and, if

necessary, top up with distilled water. Refer to the

battery manufacturer’s detailed instructions.

Lift the filter compartment cover and check under

the impermeable sponge filter for any signs of liq-

uid; if there is any, drain it off into the dirty water

tank.

8.9.3 OPERATIONS AT EXTENDED INTER-

VALS

Even though the machine was built with great pre-

cision and conforms to the most severe quality

tests, the electrical and mechanical parts will in-

evitably be subjected to wear and aging after ex-

tended periods of use.

For safe and problem-free operation, your machine

should be carefully checked every year by our au-

thorized technical service centre (or by a specialist

in the sector familiar with all the pertinent safety

regulations contained in this manual).

This type of work may have to be carried out more

frequently if the machine operates in particular/dif-

ficult situations and/or if required maintenance was

not performed.

8.10 RECOMMENDED SPARE PARTS

You’ll always be able to use your machine as effi-

ciently as possible by maintaining a stock of the

most common consumable materials and by sched-

uling routine and extraordinary maintenance. Con-

tact your dealer for a list of these spare parts.

8 - MAINTENANCE INFORMATIONS