10 Certificate of Decontamination

24 of 28

4EYS / 4EYT

1974.91/01-EN

10 Certificate of Decontamination

Type:

................................................................................................................................

Order number/

Order item number

9)

:

................................................................................................................................

Delivery date:

................................................................................................................................

Applications:

................................................................................................................................

Fluid handled

9)

:

................................................................................................................................

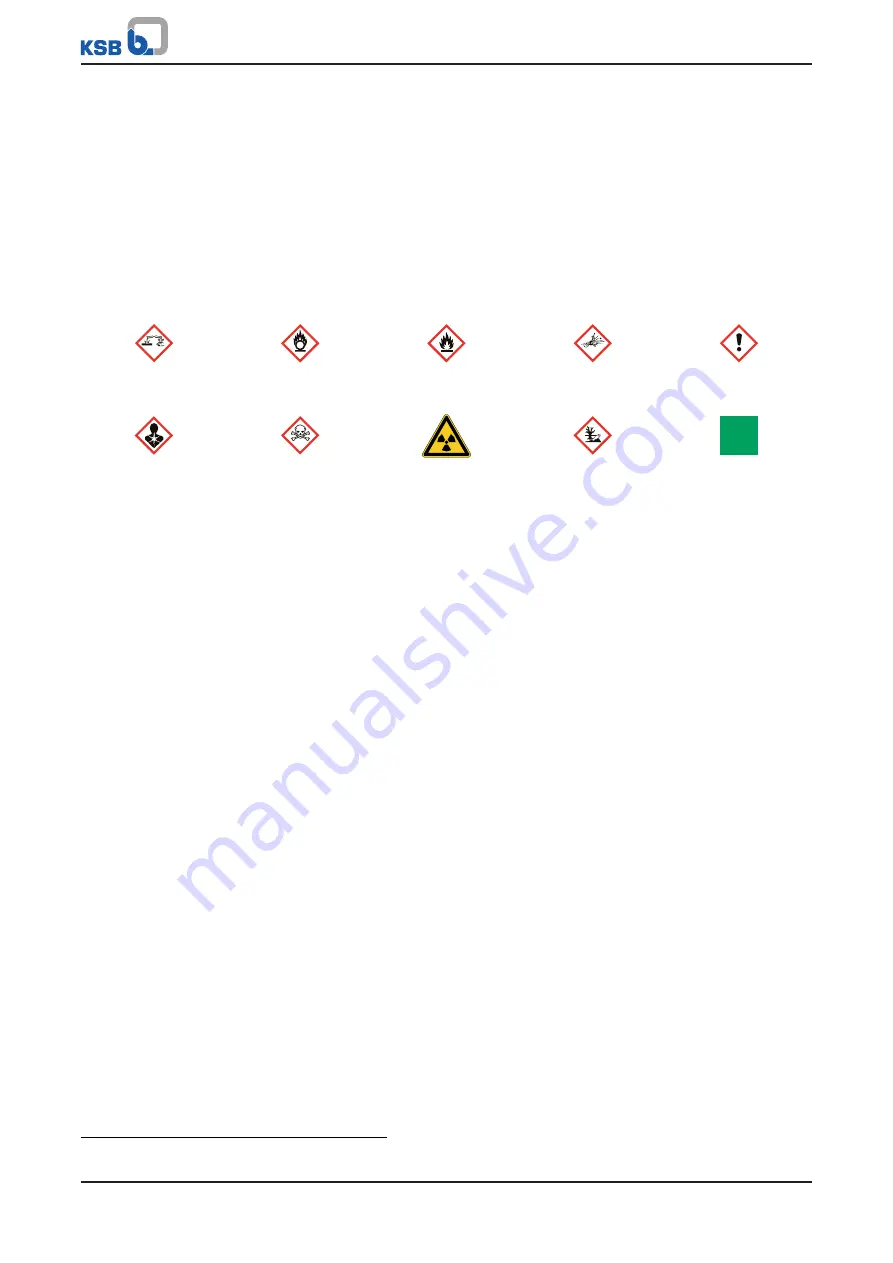

Please tick where applicable

9)

:

⃞

⃞

⃞

⃞

⃞

Corrosive

Oxidising

Flammable

Explosive

Hazardous to health

R

⃞

⃞

⃞

⃞

⃞

Seriously hazardous to

health

Toxic

Radioactive

Bio-hazardous

Safe

Reason for return

9)

:

................................................................................................................................

Comments:

................................................................................................................................

................................................................................................................................

The product/accessories have been carefully drained, cleaned and decontaminated inside and outside prior to dispatch/

placing at your disposal.

We herewith declare that this product is free from hazardous chemicals, biological and radioactive substances.

For mag-drive pumps, the inner rotor unit (impeller, casing cover, bearing ring carrier, plain bearing, inner rotor) has been

removed from the pump and cleaned. In cases of containment shroud leakage, the outer rotor, bearing bracket lantern,

leakage barrier and bearing bracket or intermediate piece have also been cleaned.

For canned motor pumps, the rotor and plain bearing have been removed from the pump for cleaning. In cases of leakage at

the stator can, the stator space has been examined for fluid leakage; if fluid handled has penetrated the stator space, it has

been removed.

⃞

No special safety precautions are required for further handling.

⃞

The following safety precautions are required for flushing fluids, fluid residues and disposal:

...............................................................................................................................................................

...............................................................................................................................................................

We confirm that the above data and information are correct and complete and that dispatch is effected in accordance with the

relevant legal provisions.

..................................................................

.......................................................

.......................................................

Place, date and signature

Address

Company stamp

9

Required fields

Summary of Contents for 4EYS

Page 1: ...KSB Mechanical Seal 4EYS 4EYT Installation Operating Manual...

Page 26: ......

Page 27: ......