For the connection to power supply observe the wiring diagrams (

67) in the Annex and the information on planning the control system. (

5.4.1 Page 27)

The pump set is supplied complete with power cables. Always use all cables provided

and connect all marked cores of the control cable.

DANGER

Incorrect wiring

Explosion hazard!

▷

The core ends must be connected outside of the potentially explosive

atmosphere or inside electrical equipment approved to equipment category

II2G.

DANGER

Operating an incompletely connected pump set

Explosion hazard!

Damage to the pump set!

▷

Never start up a pump set with incompletely connected power cables or non-

operational monitoring devices.

CAUTION

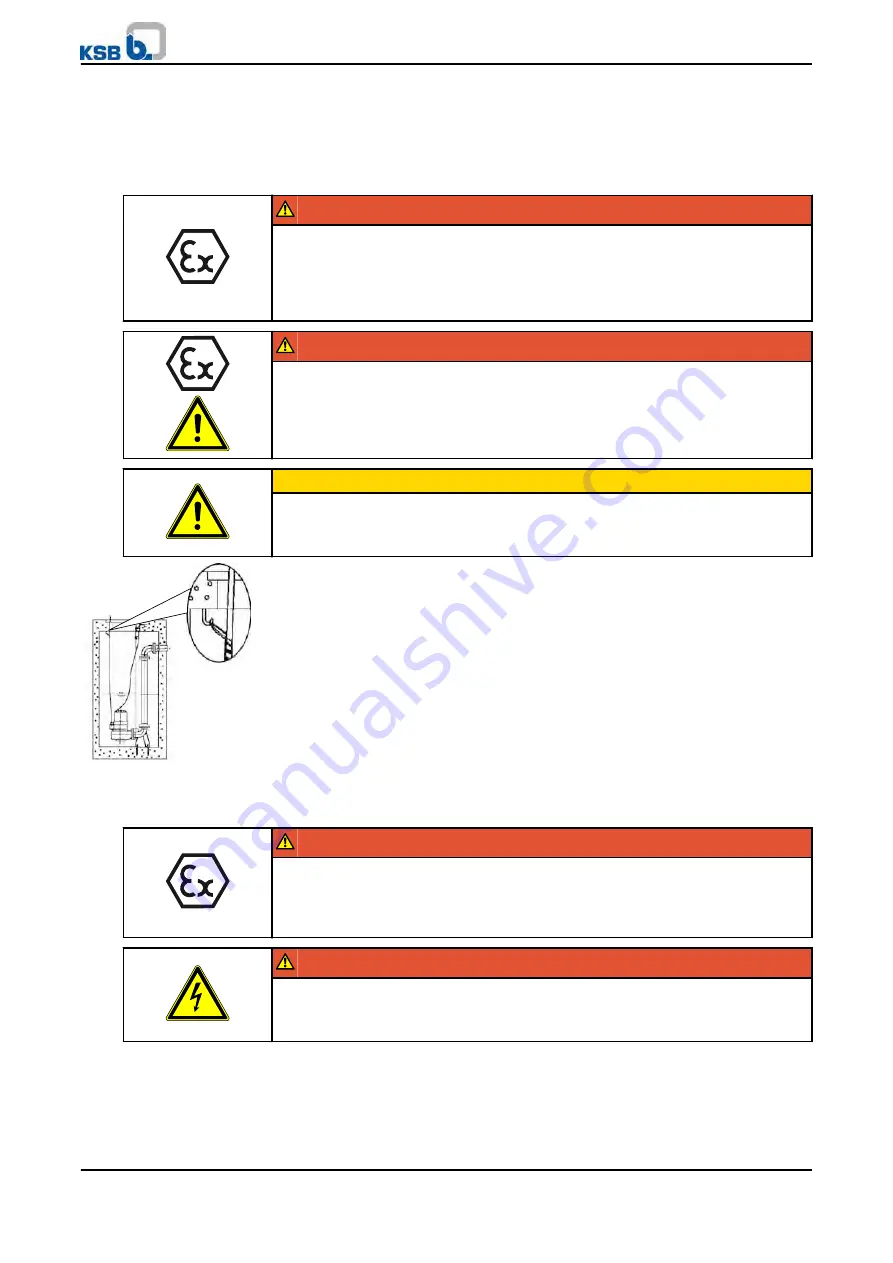

Flow-induced motion

Damage to the power cable!

▷

Run the power cable upwards with as little slack as possible.

1. Run the power cables upwards without slack and fasten them.

2. Only remove the protective caps from the power cables immediately before

connecting the cables.

3. If necessary, adjust the length of the power cables to the site requirements.

4. After shortening the cables, correctly transfer the markings of the individual

cores at the cable ends.

The pump set does not have an external PE connection (risk of corrosion).

DANGER

Incorrect wiring

Explosion hazard!

▷

Explosion-proof pump sets installed in a tank must never be retrofitted with an

external potential equalisation connection!

DANGER

Touching the pump set during operation

Electric shock!

▷

Make sure that the pump set cannot be touched during operation.

Fig. 17: Fastening the

power cables

Potential equalisation

5 Installation at Site

Amarex KRT

31 of 74

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 33 of 96