Motor sizes

5 2, 6 2, 8 2, 12 2, 17 2,

5 4, 7 4, 11 4, 16 4,

4 6, 6 6, 9 6, 12 6

23 2,

23 4, 29 4,

20 6, 26 6,

10 8, 17 8, 21 8

37 2, 55 2,

35 4, 50 4, 65 4,

32 6, 40 6, 50 6,

26 8, 35 8

Pump size

200-330

200-400/401

250-400/401

300-400/401

7.2.2.1.4 Changing the lubricant

WARNING

Lubricants posing a health hazard

Risk to persons and the environment!

▷

When draining the lubricant take appropriate measures to protect persons and

the environment.

▷

Observe all legal regulations on the disposal of liquids posing a health hazard.

WARNING

Excess pressure in the lubricant reservoir

Liquid spurting out when the lubricant reservoir is opened at operating temperature!

▷

Open the screwed plug of the lubricant reservoir very carefully.

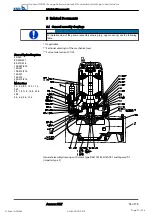

1. Position the pump set as illustrated.

903

411.03

Fig. 19: Draining the lubricant

2. Place a suitable container under the screwed plug.

3. Unscrew screwed plug 903 or 903.03 with joint ring 411.03 and, if applicable,

screwed plug 903.04 with joint ring 411.05. Drain the lubricant.

1. Position the pump set as illustrated.

903.03

411.03

903.03

411.03

Fig. 20: Filling in the lubricant

2. Pour lubricant into the lubricant filler opening until the lubricant reservoir

overflows.

3. Close screwed plug 903.03 again with a new joint ring 411.03.

7.2.2.2 Lubricating the rolling element bearings

The rolling element bearings of the pump sets are grease-packed and maintenance-

free, with the exception of those described below.

Draining the lubricant

Filling in the lubricant

7 Servicing/Maintenance

Amarex KRT

41 of 74

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 43 of 96