7.4.3.4 Removing the wear plate

✓

The back pull-out unit has been separated from the pump casing.

✓

The inside of the casing has been cleaned.

✓

Result of visual inspection: The wear plate needs to be replaced.

1. On transportable models, separate the pump casing from the piping.

2. Undo hexagon socket head cap screws 914.12.

3. Remove wear plate 135.01 and O-rings 412.34.

7.4.4 Dismantling the motor section

NOTE

Special regulations apply to repair work on explosion-proof pump sets. Modifications or

alteration of the pump set may affect explosion protection and are only permitted after

consultation with the manufacturer.

NOTE

The motors of explosion-proof pump sets are supplied in "flameproof enclosure" type of

protection. Any work on the motor section which may affect explosion protection, such as

re-winding and machining repairs, must be inspected and approved by an approved

expert or performed by the motor manufacturers. No modifications must be made to the

internal configuration of the motor space. Repair work at the flameproof joints must only

be performed in accordance with the manufacturer's instructions. Repair to the values in

tables 1 and 2 of EN 60079-1 is not permitted.

When dismantling the motor section and the power cables make sure that the cores/

terminals are clearly marked for future reassembly.

7.5

Reassembling the pump set

7.5.1 General information/Safety regulations

CAUTION

Improper reassembly

Damage to the pump!

▷

Reassemble the pump (set) in accordance with the general rules of sound

engineering practice.

▷

Use original spare parts only.

NOTE

Before reassembling the motor section, check that all joints relevant to explosion

protection (flamepaths) are undamaged. Replace any components with damaged

flamepaths. Refer to the "Flamepaths" annex for the position of the flamepaths.

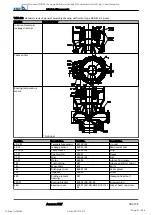

Always reassemble the pump set in accordance with the corresponding general

assembly drawing.

▪

O-rings

– Check O-rings for any damage and replace by new O-rings, if required.

– Never use O-rings that have been glued together from material sold by the

metre.

▪

Assembly adhesives

– Avoid the use of assembly adhesives, if possible.

During reassembly tighten all screws and bolts as specified in this manual. (

914.12

135

101

Fig. 24: Removing the

wear plate

Sequence

Seal elements

Tightening torques

7 Servicing/Maintenance

46 of 74

Amarex KRT

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 48 of 96