Table 10: Permissible flange loads

Nominal diameter

of the flange

Forces [N]

Moments [Nm]

F

y

F

z

F

x

∑

F

M

y

M

z

M

x

∑

M

50

1350

1650

1500

2600

1000

1150

1400

2050

80

2050

2500

2250

3950

1150

1300

1600

2350

100

2700

3350

3000

5250

1250

1450 1750

2600

150

4050

5000

4500

7850

1750

2050

2500

3650

200

5400

6700

6000 10450 2300

2650

3250

4800

250

6750

8350

7450 13050 3150

3650

4450

6550

300

8050 10000 8950 15650 4300

4950

6050

8900

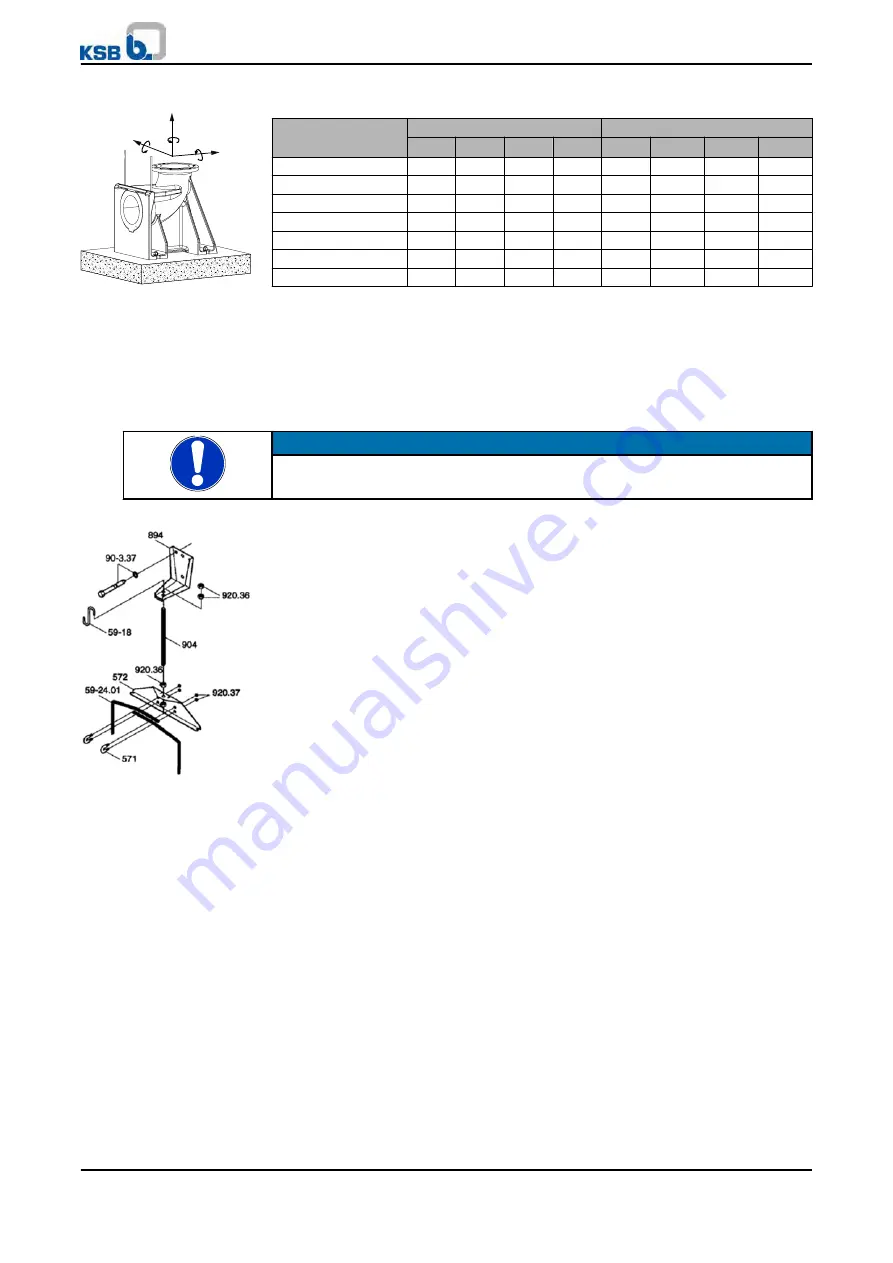

5.3.1.3 Fitting the guide wire arrangement

The pump set is guided into the sump or tank along two parallel, tightly stretched

guide wires made of stainless steel. It attaches itself automatically to the duckfoot

bend which has been fitted to the floor.

NOTE

Should site conditions/piping layout, etc. require the wire to run off the vertical, do not

exceed a maximum angle of 5° to ensure reliable fitting and guiding of the pump set.

Fitting the mounting bracket

1. Fasten mounting bracket 894 to the edge of the sump opening with steel anchor

bolts 90-3.37 and tighten the anchor bolts to a tightening torque of 10 Nm.

2. Push clamping piece 571 through the holes of suspension bracket 572 and fasten

it with nuts 920.37.

3. Fasten threaded bolt 904 with the pre-assembled clamping arrangement to the

mounting bracket with nut 920.36.

Do not tighten nut 920.36 too much in order to allow sufficient play for

subsequently tensioning the guide wire.

F

x

F

z

F

y

M

y

M

z

M

x

Fig. 8: Permissible flange

loads

Fig. 9: Fitting the

mounting bracket

5 Installation at Site

Amarex KRT

23 of 74

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 25 of 96