Connecting the piping

The DIN connection is suitable for connecting rigid or flexible pipes.

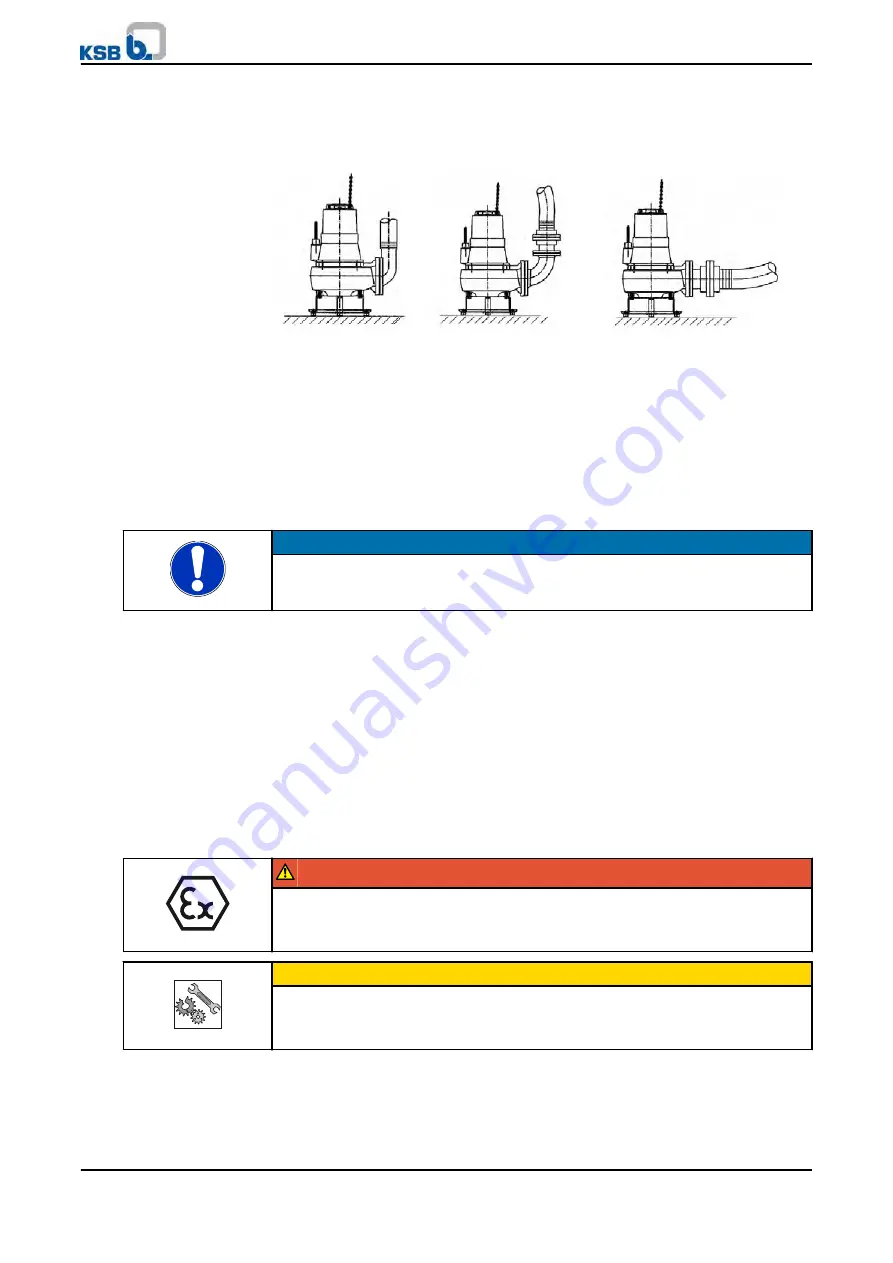

Fig. 15: Types of connection

5.4

Electrical connection

5.4.1 Information for planning the control system

For the electrical connection of the pump set observe the wiring diagrams contained

in the Annex. (

The pump set is supplied with power cables; it is designed for direct starting. Star-

delta starting is also possible.

NOTE

When laying a cable between the control system and the pump set's connection point,

make sure that the number of conductors is sufficient for the sensors. A minimum cross-

section of 1.5 mm² is required.

The motors may be connected to electrical low-voltage grids with nominal voltages

and voltage tolerances to IEC 38 or other grids or power supply facilities with

maximum nominal voltage tolerances of ± 10 %.

5.4.1.1 Overload protection

1. Protect the pump set against overloading by a thermal time-lag overload

protection device in accordance with IEC 947 and local regulations.

2. Set the overload protection device to the rated current specified on the name

5.4.1.2 Level control

DANGER

Pump set running dry

Explosion hazard!

▷

Never allow an explosion-proof pump set to run dry!

CAUTION

Fluid level below the specified minimum

Damage to the pump set by cavitation!

▷

Never allow the fluid level to drop below the specified minimum.

Automatic operation of the pump set in a tank requires the use of level control

equipment.

Observe the specified minimum fluid level. (

5 Installation at Site

Amarex KRT

27 of 74

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 29 of 96