3. Evenly tighten screwed connection 920.01 between pump casing and bearing

bracket.

CAUTION

Axial displacement of the rotor

Damage to shaft seal and bearings!

▷

Always adjust and check the axial clearance with the pump set in vertical

position.

4. Use a rubber mallet to push casing wear ring 502 in until it is close to impeller

230.

5. Suspend the pump set vertically, as illustrated.

6. Lift off the pump set and adjust the axial clearance to 0.3 ± 0.1 mm.

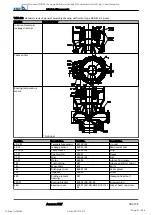

7.5.2.3.2 Design with wear plate

✓

The shaft, rolling element bearings, mechanical seal and impeller have been

assembled properly.

0.4

+0.2

mm

914.12

412.34

914.24

135

412.33

230

101

Fig. 32: Fitting the wear plate

1. Equip wear plate 135 with two new O-rings 412.33 and 412.34.

2. Insert wear plate 135 into pump casing 101.

3. Fasten wear plate 135 to pump casing 101 with socket head cap screws 914.12.

Fig. 30: Suspending the

pump set

502

904.01 101

230

0,3±0,1 mm

Fig. 31: Fitting the casing

wear ring

7 Servicing/Maintenance

50 of 74

Amarex KRT

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 52 of 96