4. Once the leak test has been successful, fill in the lubricant. (

7.5.5 Checking the connection of motor/power supply

After reassembly, carry out the measures specified in (

7.6

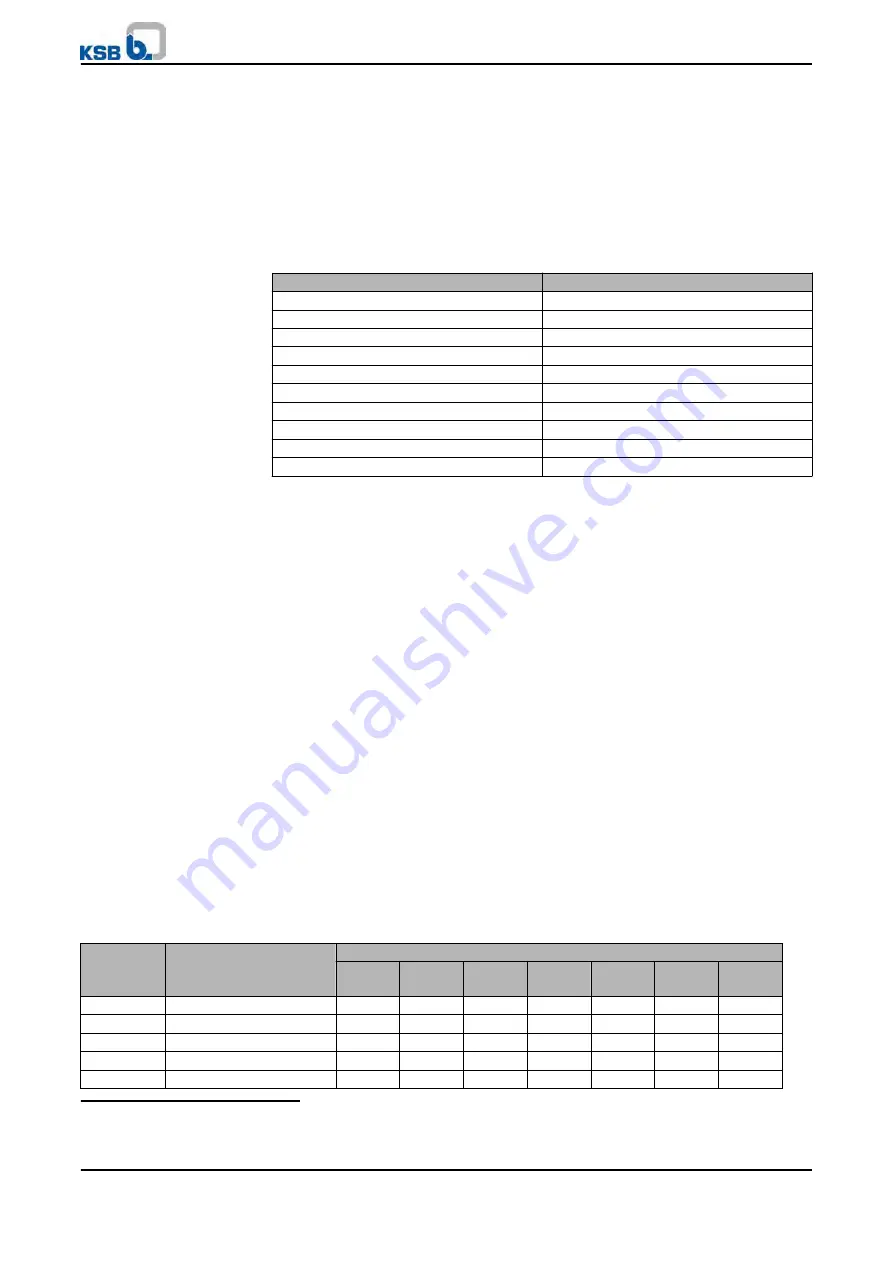

Tightening torques

Table 25: Tightening torques

Thread

Tightening torque [Nm]

M 5

4

M 6

7

M 8

17

M 10

35

M 12

60

M 16

150

M 20

290

M 24

278

M 27

409

M 30

554

7.7

Spare parts stock

7.7.1 Ordering spare parts

Always quote the following data when ordering replacement or spare parts:

▪

Pump type

▪

KSB order number

▪

Motor number

Refer to the name plate for all data. (

Also supply the following data:

▪

Part description

▪

Part No.

▪

Quantity of spare parts

▪

Shipping address

▪

Mode of dispatch (freight, mail, express freight, air freight)

Refer to the general assembly drawing for part numbers and descriptions. (

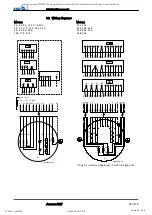

7.7.2 Recommended spare parts stock for 2 years' operation to DIN 24296

Table 26: Quantity of spare parts for recommended spare parts stock

9)

Part No.

Part description

Number of pump sets (including stand-by pump sets)

2

3

4

5

6 and 7

8 and 9

10 and

more

80-1

Motor section

-

-

-

1

1

2

30 %

834

Cable gland

1

1

2

2

2

3

40 %

818

Rotor

-

-

-

1

1

2

30 %

230

Impeller

1

1

1

2

2

3

30 %

502

Casing wear ring

2

2

2

3

3

4

50 %

9)

For two years of continuous operation or 17,800 operating hours

7 Servicing/Maintenance

52 of 74

Amarex KRT

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 54 of 96