8

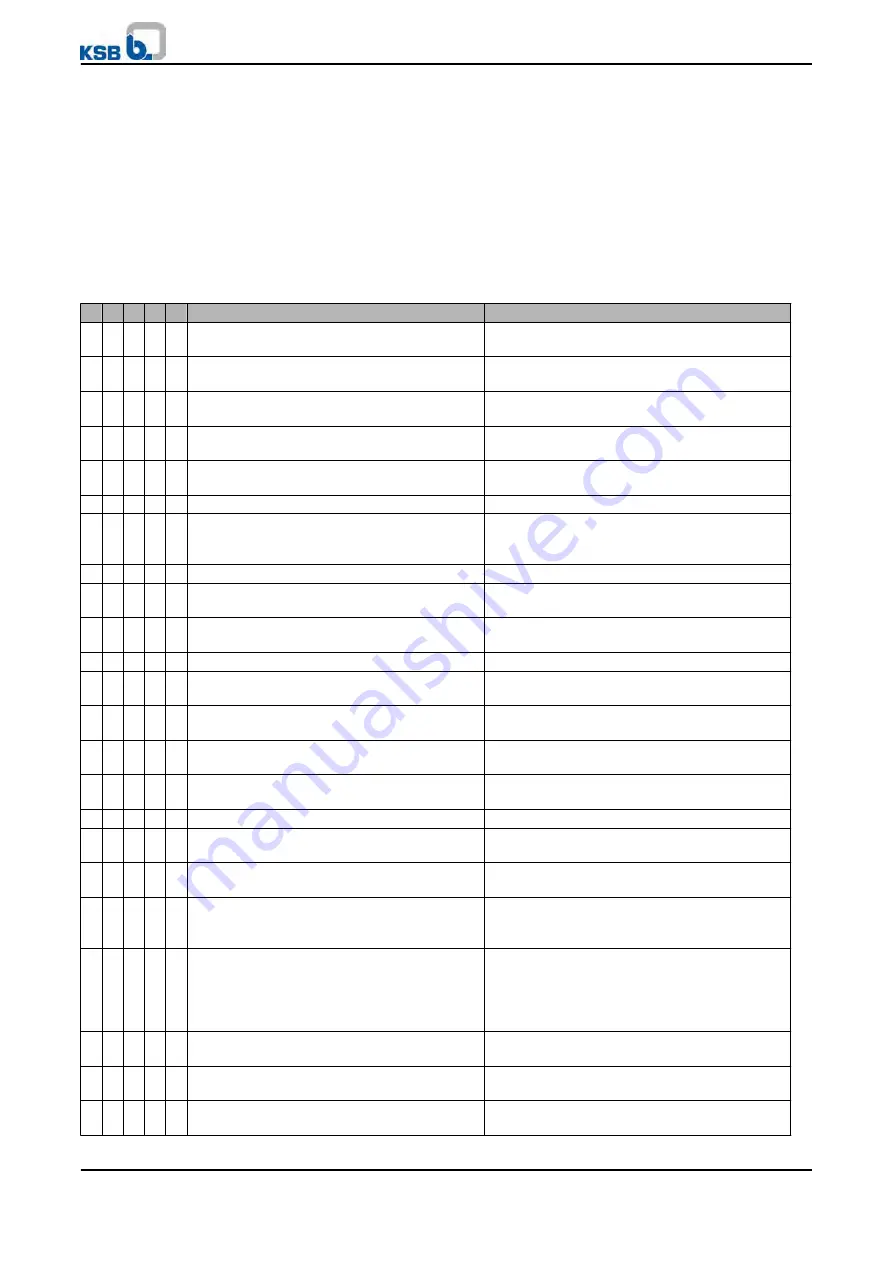

Trouble-shooting

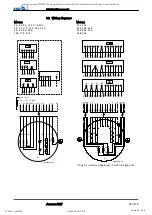

Pump is running but does not deliver

Pump delivers insufficient flow rate

Excessive current/power consumption

Insufficient discharge head

Vibrations and noise during pump operation

Table 27: Trouble-shooting

A B C D E Possible cause

Remedy

X

Pump delivers against an excessively high

discharge pressure.

Re-adjust to duty point.

X

Gate valve in the discharge line is not fully

open.

Fully open the gate valve.

X

X Pump is running in the off-design range (low

flow / overload).

Check the pump's operating data.

X

Pump or piping are not completely vented.

Vent by lifting the pump off the duckfoot bend

and lowering it again.

X

Pump intake clogged by deposits.

Clean the intake, pump components and non-

return valve.

X

X X Suction line or impeller clogged.

Remove deposits in the pump and/or piping.

X

X Dirt/fibres in the clearance between the

casing wall and impeller of a sluggish rotor.

Check whether the impeller can be easily

rotated.

Clean the impeller, if required.

X X X X Wear of internal pump parts

Replace worn parts by new ones

X X

X

Defective riser (pipe and seal elements).

Replace defective riser pipes,

replace seal elements

X

X X Impermissible air or gas content in the fluid

handled

Contact KSB.

X System-induced vibrations

Contact KSB.

X X X X Wrong direction of rotation

Check the connection of the motor and

switchgear, if any.

X

Wrong supply voltage

Check the mains power supply.

Check the connection of the power cables.

X

Motor is not running because of lack of

voltage.

Check the electrical installations.

Contact the energy supplier.

X

X

Motor winding or power cable are defective. Replace by new original KSB parts or contact

KSB.

X Defective rolling element bearing

Contact KSB.

X

X

In case of star-delta configuration: motor

running in star configuration only.

Check star-delta contactor.

X

Water level lowered too much during

operation.

Check the level control.

X

The temperature switch monitoring the

winding has tripped because of excessive

temperature rise in the winding.

The motor will restart automatically once the

winding has cooled down.

X

Thermistor tripping unit with manual reset

for temperature limiter (explosion protection)

has tripped the pump as a result of the

permissible winding temperature being

exceeded.

Assign qualified and trained personnel to

determine and remedy the cause of failure.

X

The leakage monitoring system of the motor

has tripped.

Assign qualified and trained personnel to

determine and remedy the cause of failure.

X

The mechanical seal monitoring system has

tripped.

Assign qualified and trained personnel to

determine and remedy the cause of failure.

X

The bearing temperature monitoring system

has tripped

Assign qualified and trained personnel to

determine and remedy the cause of failure.

A

B

C

D

E

8 Trouble-shooting

54 of 74

Amarex KRT

Goodnal STP ST041 Sewage Delivery (Amarex KRT Submersible Motor Pump) Vendor Manual

Q-Pulse Id VM362

Active 29/10/2013

Page 56 of 96