3

Transport/Temporary Storage/Disposal

3.1

Transport

DANGER

Improper transport

Danger to life from falling parts!

Damage to the pump set!

▷

Use the attachment point provided (eyebolt, lifting lug or bail) for attaching

lifting accessories.

▷

Never suspend the pump set by its power cable.

▷

Never use chains or lifting ropes included in KSB's scope of supply for lifting

loads other than the KSB product supplied.

▷

Safely attach transport ropes or chains to the pump and crane.

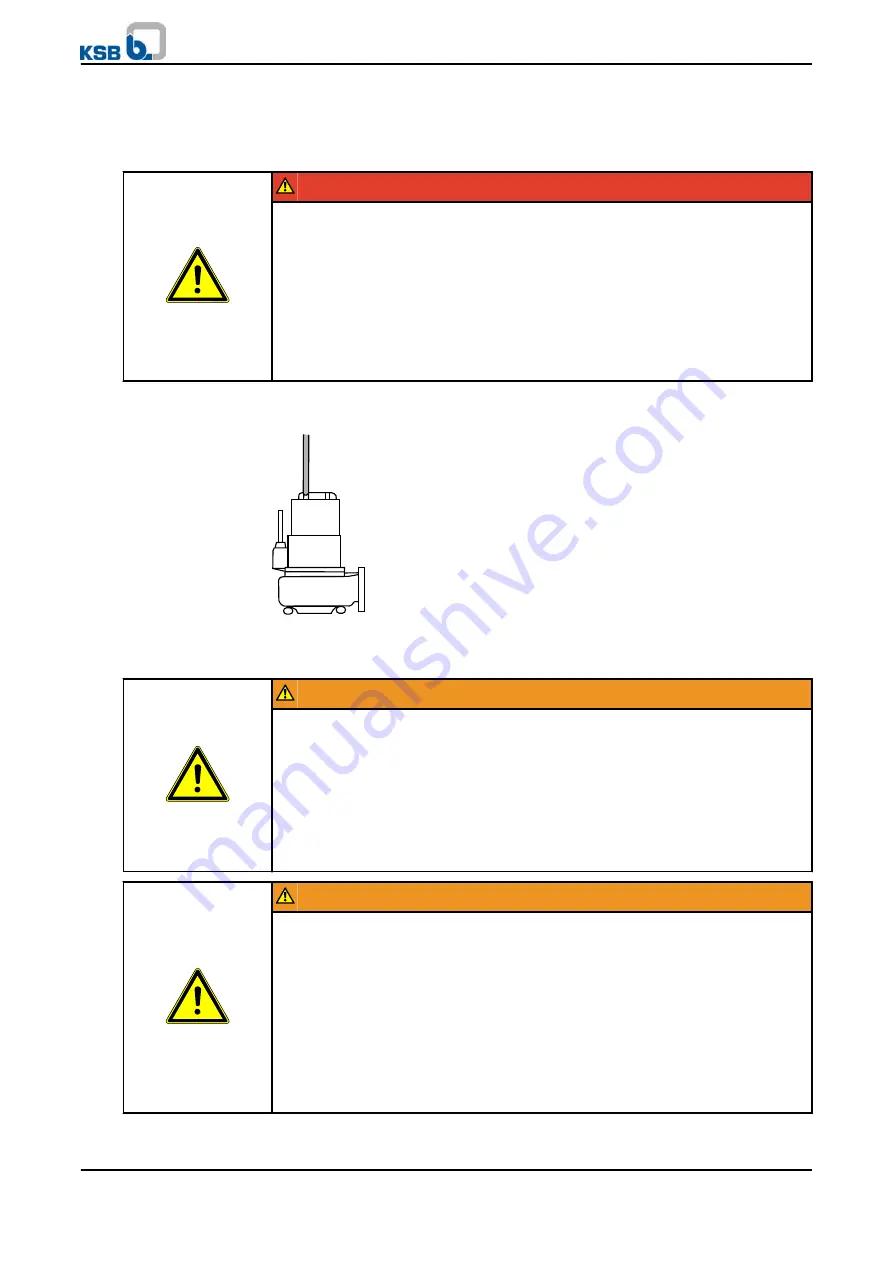

Transport the pump set as shown.

Fig. 1: Transporting the pump set

Setting down the pump set

WARNING

Placing the pump set on an unsecured and uneven mounting surface

Personal injury and damage to property!

▷

Always place the pump set on a solid and level surface with the pump set in

vertical position and the motor on top.

▷

Only place the pump set on a surface of sufficient load-carrying capacity.

▷

Use appropriate means to secure the pump set against overturning or tipping

over.

▷

Refer to the weights given in the data sheet/name plate.

WARNING

Improper placing of pump sets in vertical/horizontal position

Personal injury and damage to property!

▷

Use appropriate means to secure the pump set against overturning or tipping

over.

▷

Use two lifting devices when handling large pump sets, if possible (using the

attachment point provided on the motor and the discharge nozzle).

▷

Secure power cables against falling.

▷

Use additional supports for the transport holder to secure the pump set against

overturning.

▷

Maintain sufficient safety distance when lifting the pump set.

3 Transport/Temporary Storage/Disposal

Amarex KRT

13 of 78

Summary of Contents for Amarex KRT

Page 77: ......