5 Installation at Site

20 of 72

Amarex N

Place of installation for transportable models

WARNING

Incorrect positioning

Personal injury and damage to property!

▷

Place the pump set down in a vertical position with the motor on top.

▷

Use appropriate means to secure the pump set against tilting and tipping over.

▷

Refer to the weights given in the data sheet/on the name plate.

Resonances

Any resonances at the usual excitation frequencies (1 x and 2 x rotational frequency,

rotational noise) must be prevented both in the foundation and in the connected

piping, as such frequencies may cause extreme vibrations.

1.

Check the structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing/general arrangement drawing.

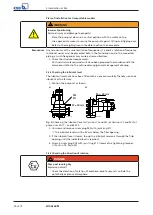

5.2.2 Checking the lubricant level

The lubricant reservoirs have been filled with an environmentally friendly, non-toxic

lubricant at the factory.

1.

Position the pump set as shown.

a)

b)

M = 40 mm

2563:109

2563:108

M = 40 mm

903

411

Fig. 2:

Checking the lubricant level a) Versions YL and WL; b) Versions YL and WL for

pump sizes 50-17... and 65-220

2.

Unscrew and remove screw plug 903 with joint ring 411.

ð

The lubricant level must be 40 mm below the filler opening.

3.

If the lubricant level is lower, top up the lubricant reservoir through the filler

opening until the indicated level is reached.

4.

Screw in screw plug 903 with joint ring 411. Observe the tightening torques.

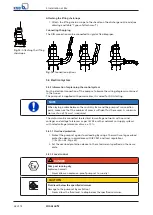

5.2.3 Checking the direction of rotation

DANGER

Pump set running dry

Explosion hazard!

▷

Check the direction of rotation of explosion-proof pump sets outside the

potentially explosive atmosphere.

Summary of Contents for Amarex N

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......