7 Servicing/Maintenance

42 of 72

Amarex N

7.2.2 Lubrication and lubricant change

7.2.2.1 Lubricating the mechanical seal

The mechanical seal is supplied with lubricant from the lubricant reservoir.

7.2.2.1.1 Intervals

Change the lubricant every 4000 operating hours but at least once a year.

7.2.2.1.2 Lubricant quality

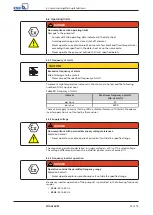

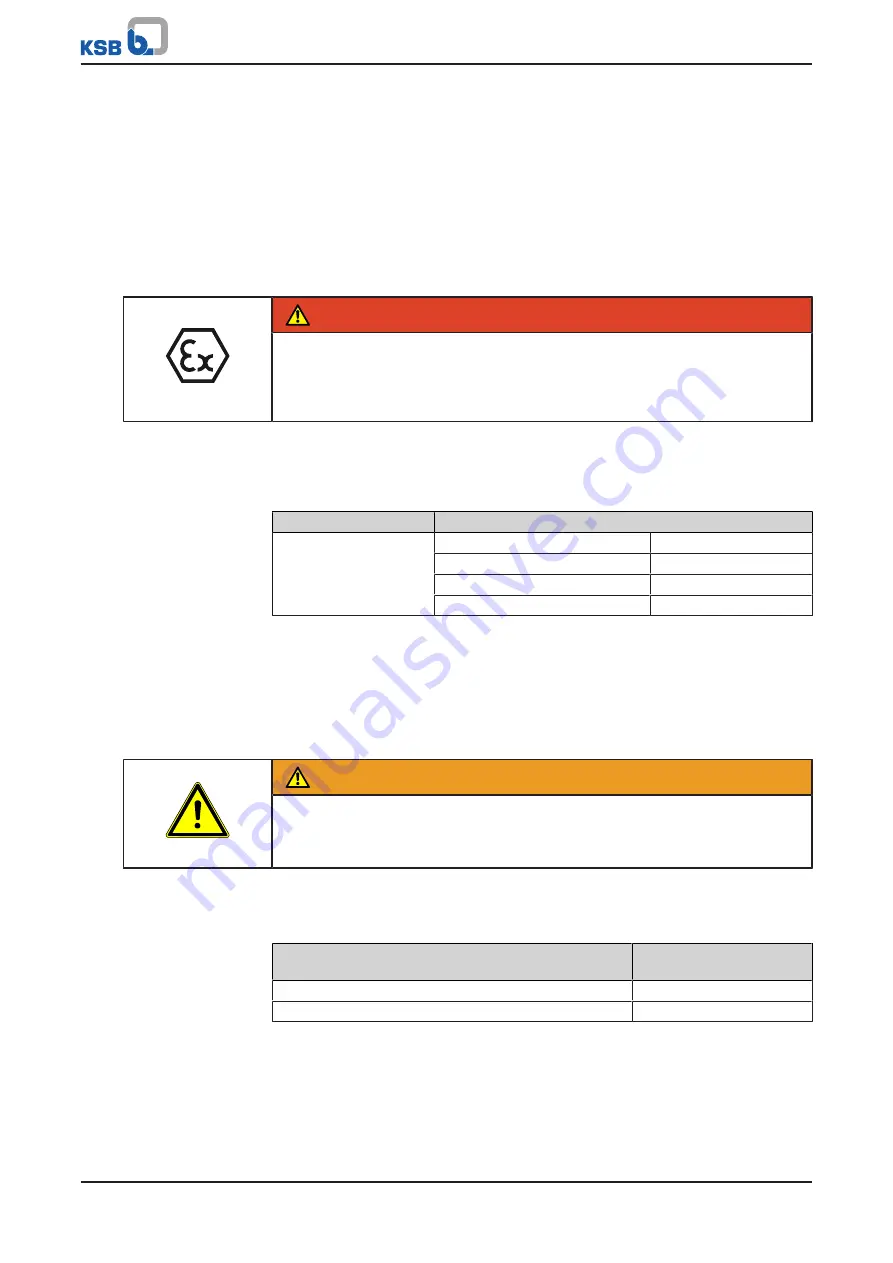

DANGER

Incorrect lubricant quality

Explosion hazard!

▷

For explosion-proof pump sets always use a lubricant whose ignition

temperature exceeds 185 °C.

The lubricant reservoir is filled at the factory with an environmentally friendly, non-

toxic lubricant of medical quality (unless otherwise specified by the customer).

The following lubricants can be used to lubricate the mechanical seals:

Table 18:

Oil quality

Description

Properties

Paraffin oil or white oil

Alternative: motor oils

of grade SAE 10W to

SAE 20W

Kinematic viscosity at 40 °C

<20 mm²/s

Ignition temperature

>185 °C

Flash point (to Cleveland)

+160 °C

Solidification point (pour point)

-15 °C

Recommended oil quality:

▪

Merkur WOP 40 PB, made by SASOL

▪

Merkur white oil Pharma 40, made by DEA

▪

Thin-bodied paraffin oil No. 7174, made by Merck

▪

Thin-bodied paraffin oil, type Clarex OM, made by HAFA

▪

Equivalent brands of medical quality, non-toxic

▪

Water-glycol mixture

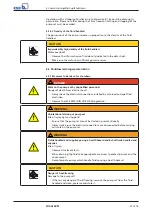

WARNING

Lubricant contaminating fluid handled

Hazard to persons and the environment!

▷

Using machine oil is only permitted if the oil is disposed of properly.

7.2.2.1.3 Lubricant quantity

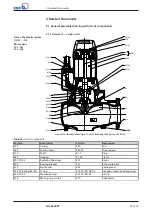

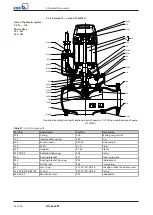

Table 19:

Lubricant quantity

Motor version

Lubricant quantity

[l]

YL and WL

0.74

UL

0.25

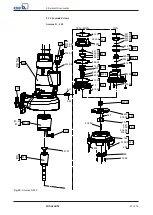

Summary of Contents for Amarex N

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......