7 Servicing/Maintenance

44 of 72

Amarex N

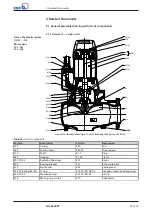

a)

b)

M = 40 mm

2563:109

2563:108

M = 40 mm

903

411

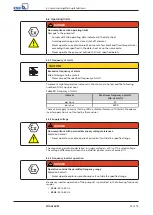

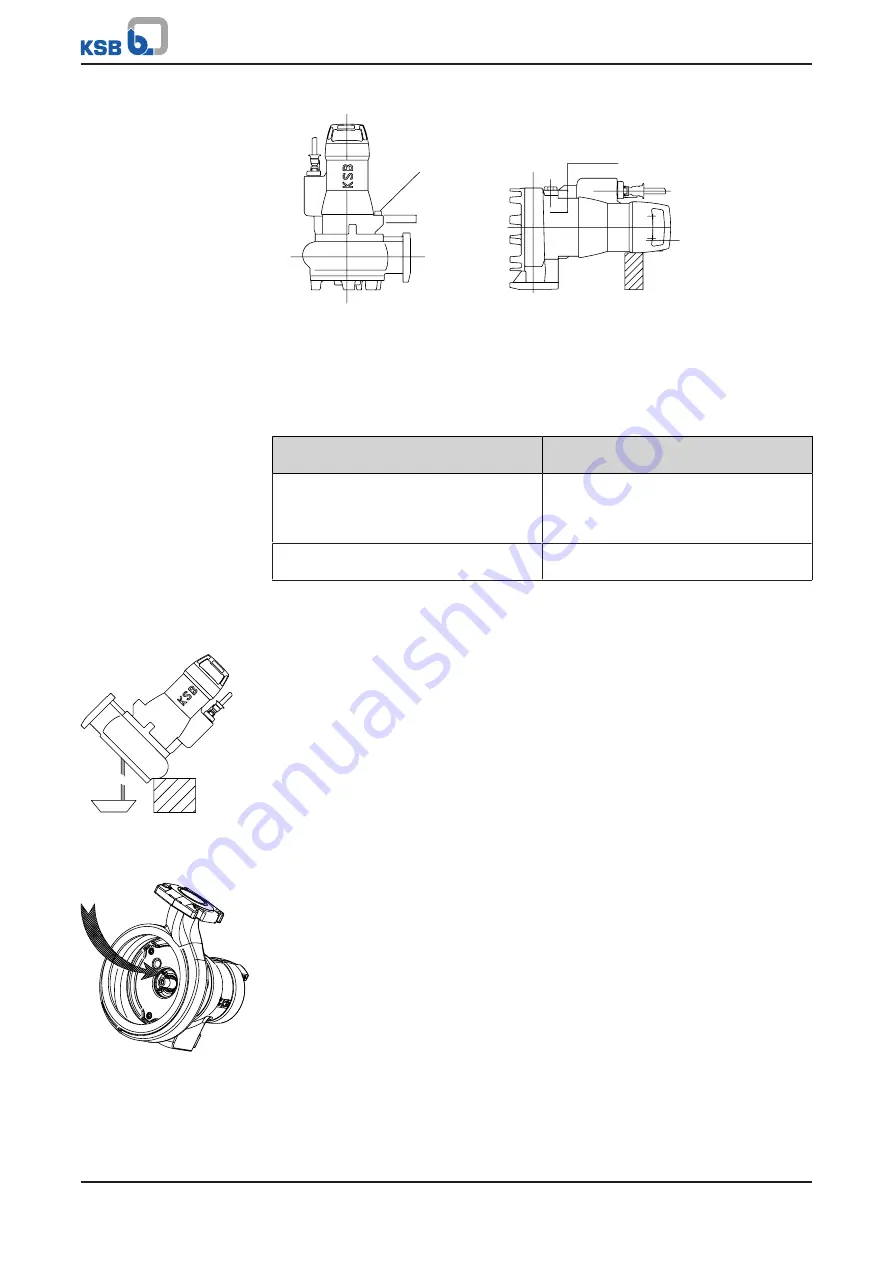

Fig. 20:

Topping up the lubricant a) Versions YL and WL; b) Versions YL, WL for pump

sizes 50-170... and 65-220

2.

Fill lubricant through the lubricant filler opening until the lubricant in the

lubricant reservoir reaches the required level M (see the following table).

3.

Screw in screw plug 903 with new joint ring 411. Tighten to a torque of 23 Nm.

Table 20:

Lubricant level

Motor sizes

M

[mm]

50-22*

65-170

80-220

100-220 (versions YL and WL)

40

50-17*

65-220 (versions YL and WL)

40

7.2.2.1.4.2 Changing the lubricant — version UL

Draining the lubricant

2563:112

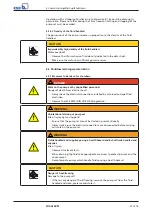

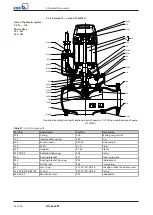

Fig. 21:

Draining the

lubricant

ü

The suction cover and the impeller have been removed.

1.

Place a suitable container under the pump set.

2.

Move mechanical seal 433.02 along the shaft.

3.

Drain the oil.

Filling in the lubricant

2563:124

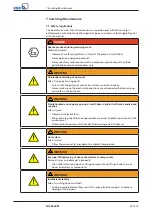

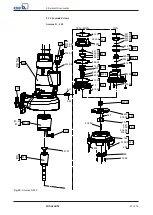

Fig. 22:

Filling in the

lubricant

1.

Fill 0.25 litres of oil through the opening between the stationary part of

mechanical seal 433.02 and rotor 818.

2.

Thoroughly clean rotor 818 and the contact face of the stationary part of

mechanical seal 433.02. Remove any oil residues.

3.

Fit the rotating part of mechanical seal 433.02.

4.

Fit impeller 230 and suction cover 162. Observe the tightening torques.

7.2.2.2 Lubricating the rolling element bearings

The rolling element bearings of the pump sets are grease-packed and maintenance-

free.

Summary of Contents for Amarex N

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......