8 Trouble-shooting

54 of 72

Amarex N

8 Trouble-shooting

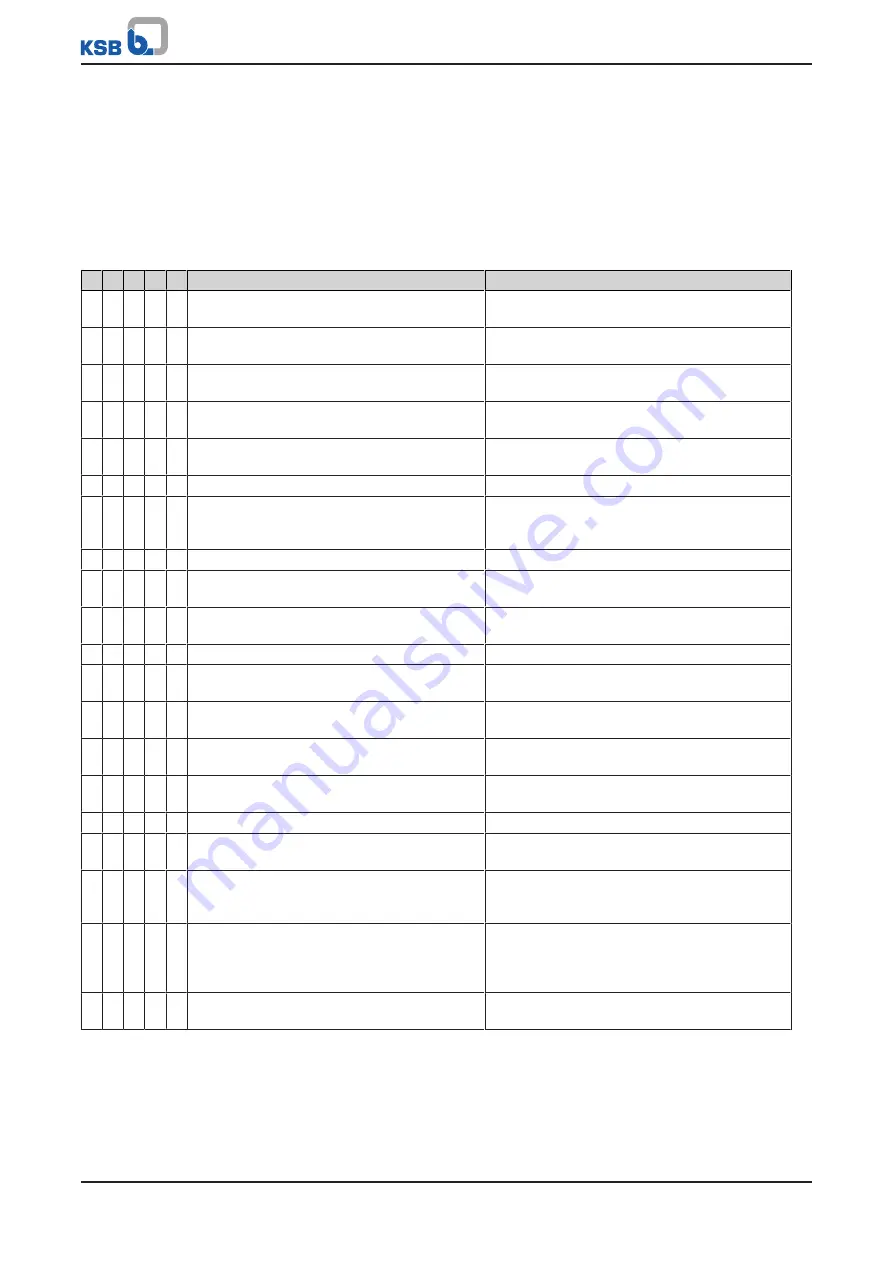

A

Pump is running, but does not deliver

B

Pump delivers insufficient flow rate

C

Excessive current/power consumption

D

Insufficient discharge head

E

Vibrations and noise during pump operation

Table 25:

Trouble-shooting

A B C D E Possible cause

Remedy

X

Pump delivers against an excessively high

pressure.

Re-adjust to duty point.

X

Gate valve in the discharge line is not fully

open.

Fully open the gate valve.

X

X

Pump is running in the off-design range (low

flow/overload).

Check the pump's operating data.

X

Pump or piping are not completely vented.

Vent by lifting the pump off the duckfoot bend

and lowering it again.

X

Pump intake clogged by deposits

Clean the intake, pump components and non-

return valve.

X

X X

Suction line or impeller clogged.

Remove deposits in the pump and/or piping.

X

X

Dirt/fibres in the clearance between the

casing wall and impeller; sluggish rotor

Check whether the impeller can be easily

rotated.

Clean the impeller, if required.

X X X X

Wear of internal parts

Replace worn parts by new ones.

X X

X

Defective riser (pipe and sealing elements)

Replace defective riser pipes,

replace sealing elements.

X

X X

Impermissible air or gas content in the fluid

handled

Contact KSB.

X

System-induced vibrations

Contact KSB.

X X X X

Wrong direction of rotation

Check the connection of the motor and

switchgear, if any.

X

Wrong supply voltage

Check the power cable.

Check the cable connections.

X

Motor is not running because of lack of

voltage.

Check the electrical installation.

Contact the energy supplier.

X

X

Motor winding or power cable are defective.

Replace by new original KSB parts or contact

KSB.

X

Defective rolling element bearing

Contact KSB.

X

Water level lowered too much during

operation.

Check level control equipment.

X

The temperature control device for

monitoring the winding has tripped due to

excessive winding temperature.

The motor will restart automatically once it has

cooled down.

X

Temperature limiter (explosion protection)

has tripped the pump as a result of the

permissible winding temperature being

exceeded.

Have cause determined and eliminated by

qualified and trained personnel.

X

Motor has been tripped by leakage monitor.

Have cause determined and eliminated by

qualified and trained personnel.

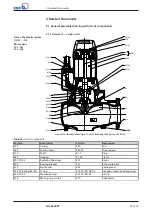

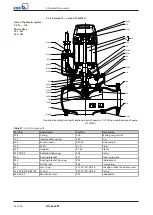

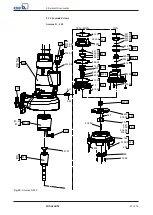

Summary of Contents for Amarex N

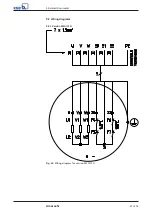

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......