9 Related Documents

65 of 72

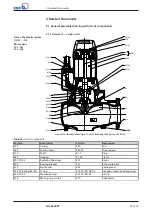

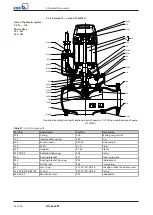

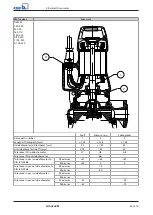

Amarex N

Motor sizes

Pump set

DKN 92

F 50-220

S50-22...

F65-170

F 80-220

D 80-220

F 100-220

D 100-220

3

1

2

Shaft

Pump casing

Cable gland

Flamepath number

1

2

3

Length of flamepath [mm]

≥ 12.5

≥ 12.5

≥ 12.5

Inside diameter (drilled hole) [mm]

30

≥ 152

32

Outside diameter (shaft) [mm]

29,9

152

32

Tolerance ISO inside diameter

F7

H8

H8

Tolerance ISO outside diameter

-

g6

-

Tolerance in µm inside diameter to

DIN ISO 286/2

Maximum

+41

+63

+39

Minimum

+20

0

0

Tolerance in µm outside diameter to

DIN ISO 286/2

Maximum

-

-14

-

Minimum

-

-39

-

Tolerance in µm inside diameter

Maximum

-

-

-

Minimum

-

-

-

Tolerance in µm outside diameter

Maximum

-40

-

-25

Minimum

-60

-

-75

Summary of Contents for Amarex N

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......