7 Servicing/Maintenance

46 of 72

Amarex N

WARNING

Components with sharp edges

Risk of cutting or shearing injuries!

▷

Always use appropriate caution for installation and dismantling work.

▷

Wear work gloves.

7.4.2 Preparing the pump set

ü

The notes and steps stated in

have been observed/

carried out.

1.

De-energise the pump set and secure it against unintentional start-up.

2.

Drain the lubricant.

3.

Drain the leakage chamber and leave it open for the duration of the

disassembly.

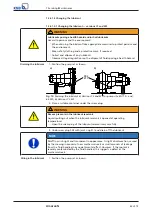

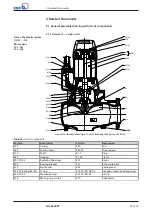

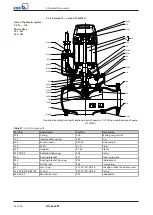

7.4.3 Dismantling the pump section

Dismantle the pump section in accordance with the relevant general assembly

drawing.

1.

Remove suction cover 162.

2.

Undo and remove the M8 impeller fastening screw.

The impeller/shaft connection is a tapered fit.

3.

For removing the impeller, an M10 jacking thread is provided at the impeller

hub.

Screw in the jack as shown in the drawing below and remove the impeller.

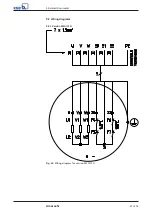

Fig. 23:

Forcing screw

NOTE

The forcing screw is not included in the scope of supply. It can be ordered

separately from KSB.

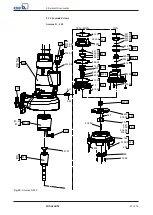

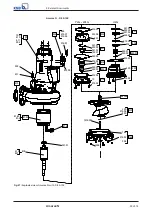

7.4.4 Removing the mechanical seal and motor section

7.4.4.1 Removing the mechanical seal and motor section (versions YLG and WLG)

NOTE

Special regulations apply to repair work on explosion-proof pump sets.

Modifications or alteration of the pump set may affect explosion protection and are

only permitted after consultation with the manufacturer.

Summary of Contents for Amarex N

Page 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Page 70: ......

Page 71: ......