6 Commissioning/Start-up/Shutdown

23 of 50

8417.8/20-EN

6 Commissioning/Start-up/Shutdown

6.1 Commissioning

CAUTION

Welding beads, scale and other impurities in the piping

Damage to the valve!

▷

Remove any impurities from the piping, e.g. by flushing the pipe with the valve

in fully open position.

▷

If necessary, install a strainer.

DANGER

All work performed on the actuator:

Risk of injury!

▷

Observe the operating manuals of actuator and accessories.

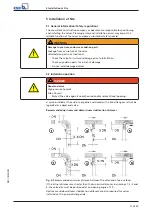

6.1.1 Prerequisites for commissioning

DANGER

Risk of pressure surges / water hammer

Danger to life caused by burns or scalds!

▷

Do not exceed the valve's maximum permissible pressure.

▷

The operator shall provide general safety measures for the system.

Before commissioning/start-up of the valve ensure that the following requirements

are met:

▪

The valve has been connected to the piping at both ends.

▪

The shut-off function of the installed valve has been checked by opening and

closing it several times.

▪

The actuator has been connected to the power supply in accordance with the

actuator's operating manual.

▪

The piping has been flushed.

▪

The material, pressure data and temperature data of the valve are compatible

with the operating conditions of the piping. (

▪

The material's chemical resistance and stability under load have been checked.

6.1.2 Actuation/operation

6.1.2.1 Actuating element – lever

For actuation open the locking device in the upper part of the yoke. Move the lever

in opening or closing direction as required and lock it in position with the locking

device.

Viewed from above, the valve is opened by turning the lever in clockwise direction,

and closed by turning the handwheel in counter-clockwise direction.

6.1.2.2 Actuating element – manual gearbox

The display on the manual gearbox indicates the position of the valve disc. Turn the

handwheel up to the stop in open or closed position, as required.

To move the valve into closed position, turn the handwheel clockwise. To move the

valve into open position, turn the handwheel anti-clockwise.

Summary of Contents for BOAX-B

Page 1: ...Butterfly Valve Installation Operating Manual ...

Page 49: ......