K.S.F.

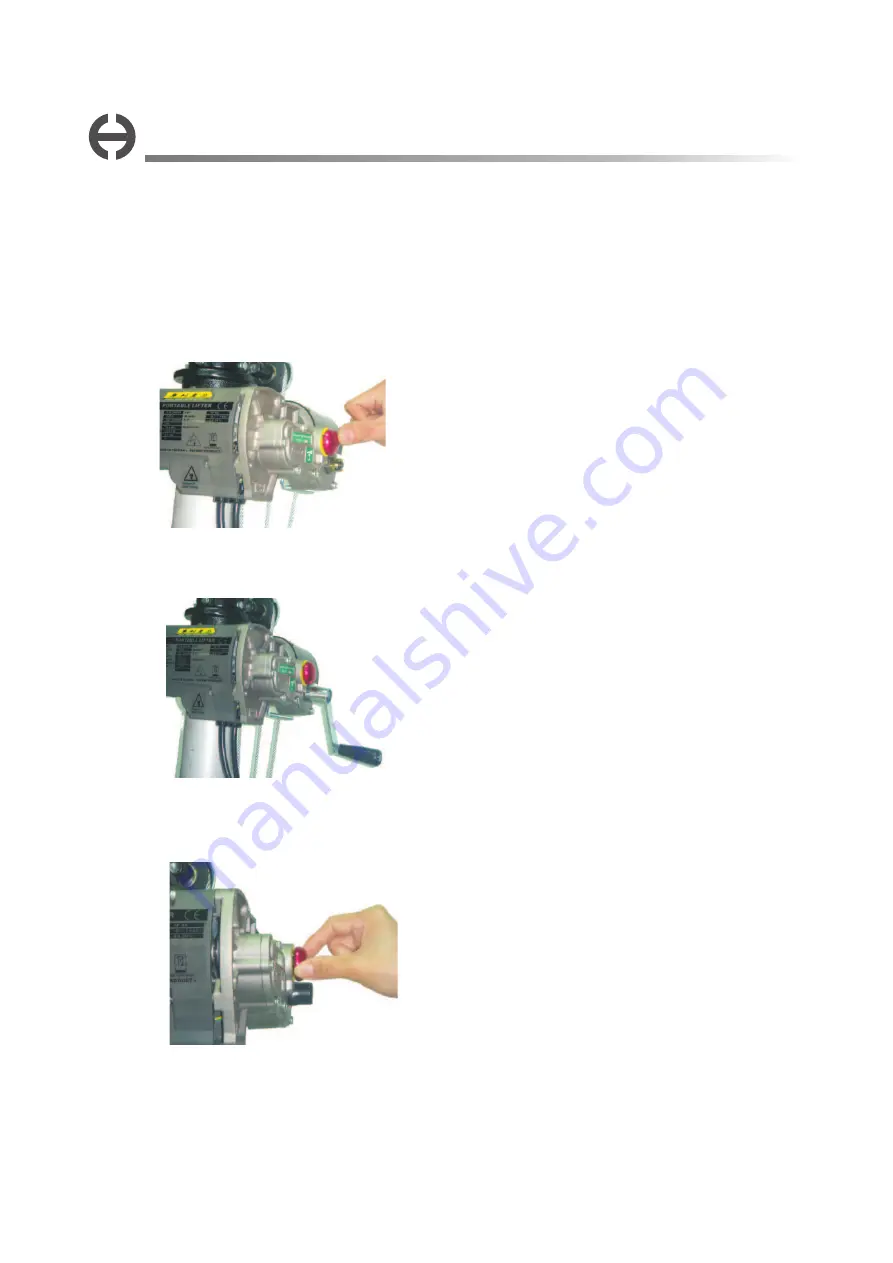

13. EMERGENCY STOP BUTTON ,

MANUALLY

1. When the unexpect situation is happening,

press the emergency stop button, the

machine will stop raising or lowering

immediately.

2. Manually: Mounted the manual handle

on and rotate it raising or lowering.

WARNING!!

When operation in manual,

operator must be squatting below

the basic height of Portable Lifter.

~

~

19

3. Pull the Emergency Stop Button up to

operating in electrically.

IF EMERGENCY STOP BUTTON CAN NOT BE

PULLED UP, YOU MAY PRESS THE TRIGGER

OF THE SWITCH BOX SLIGHTLY AS SOFT

START WITH YOUR RIGHT HAND, AND

TWIST THE EMERGENCY STOP BUTTON A

LITTLE BIT WITH YOUR LEFT HAND AS

SHOWN, THEN PULL IT UP.

This is not damaged, it because the gear in the

gear box is engaged.

Summary of Contents for CA 400 GL

Page 1: ...CA 400 GL SAFETY MODEL CA 400 GL KeM Tech KSF UPTER design ...

Page 2: ......

Page 15: ...7 STORE DIMENSION K S F 13 960m m 550mm 650m m ...

Page 16: ...8 OPERATING DIMENSION 1 K S F 14 970mm 3960 mm 1010 mm ...

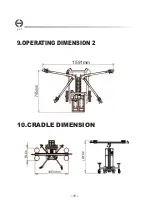

Page 17: ...10 CRADLE DIMENSION 9 OPERATING DIMENSION 2 K S F 15 1591mm 745m m 530 mm 1200 mm 1450mm ...

Page 29: ...K S F K S F 17 Explode View of Motor and Gearbox 27 ...

Page 30: ...K S F K S F 18 Explode View of CA 400 28 ...

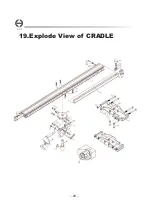

Page 31: ...19 Explode View of CRADLE K S F 29 ...

Page 32: ...KSF ...