3

Installation

! WARNING

INJECTION HAZARD

To reduce the risk of a serious injury,

always follow the

Pressure Relief Procedure

on page 3 whenever you are

instructed to relieve the pressure.

FIRE AND EXPLOSION HAZARD

To reduce the risk of static sparking, which can cause a

fire or explosion and result in serious injury, including

electric

shock, and property damage, always follow these

Precautions.

_

Read and follow the warnings in FIRE and EXPLOSION

HAZARD on page 2.

_

Provide electrical grounding continuity throughout

the entire spray system as instructed below.

_

Have a trained and qualified person perform all

electrical wiring.

_

Comply with all applicable local, state and

national fire, electrical and other safety

regulations.

INJECTION HAZARD

Your spray system must have a bleed type

master air valve and a fluid drain

valve. These two accessories help reduce

the risk of serious injury, including fluid injection,

splashing in the eyes or on the skin, or injury

from moving parts, if you are adjusting or repairing

the pump or gun.

1. Connect a grounded fluid hose to the gun fluid inlet.

2. Without the spray tip installed, start the pump or sprayer and flush and prime it according to the pump or sprayer instructions.

3. Relieve the pressure.

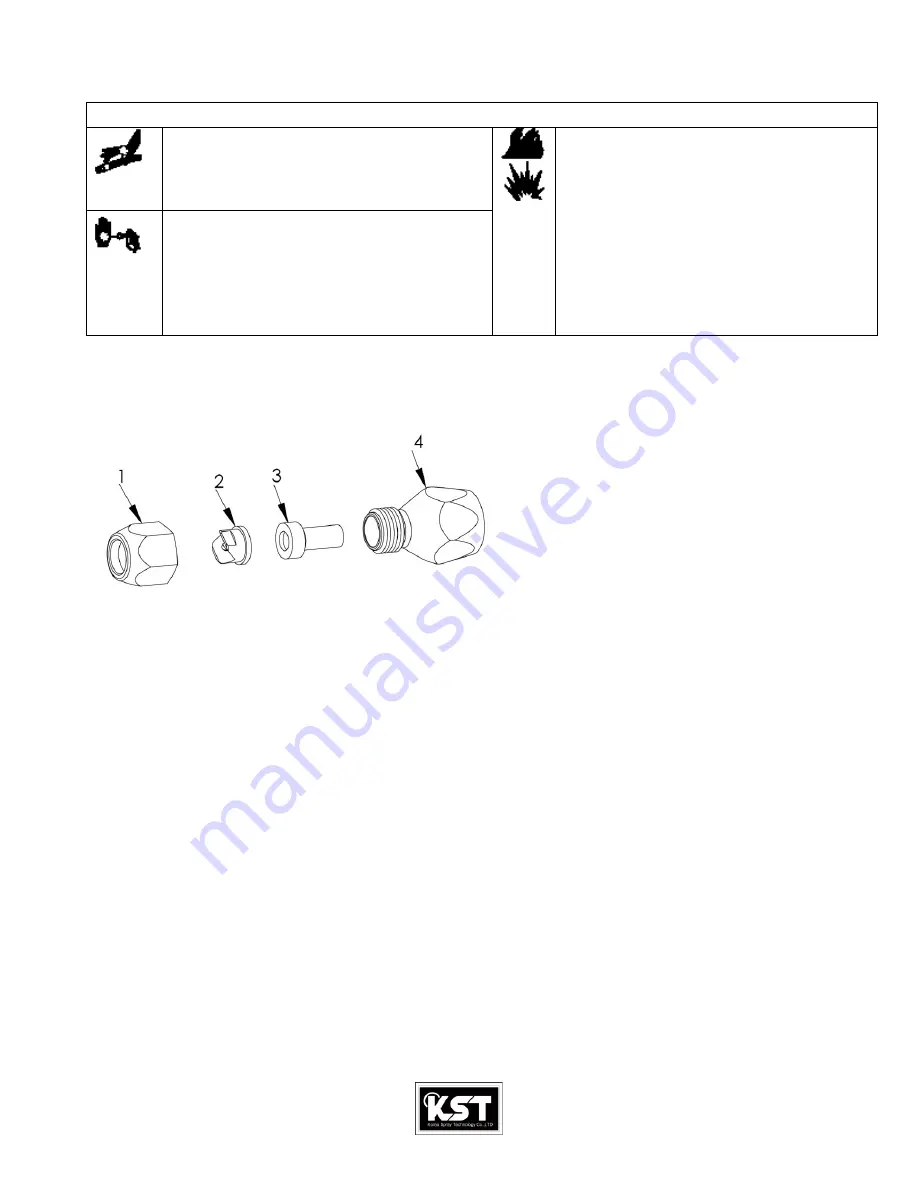

4. With the gun safety Trigger lock, unscrew the tip guard (1) and install the tip (2) and filter assembly (3) in the tip guard nut. Screw the

assembly firmly onto the gun. Tighten with a wrench. See Fig. 1.

5. Strain the fluid you are spraying if it contains particles which clog the spray tip.

FIG1.

Required Accessories

1. The

bleed-type master air valve

relieves air trapped between this valve and the pump after the air regulator is shut off. Trapped air can

cause the pump to cycle unexpectedly.

2. The

fluid drain valve

assists in relieving fluid pressure in the displacement pump, hose and gun; triggering the gun to relieve pressure may

not be sufficient.

Electrical Grounding

1. Provide electrical grounding for the

pump or sprayer

as instructed in its separate manual.

2. Provide electrical grounding for the

air compressor or hydraulic power supply

according to the local code and the manufacturer’s

recommendations.

3. Use only electrically conductive

fluid hoses

with a maximum of 500 feet (150 m) combined hose length to ensure grounding continuity.

4. Obtain electrical grounding continuity for the

spray gun

by connecting it to a properly grounding fluid hose and pump or sprayer.

5. Provide electrical grounding for these components according to the local code: the

fluid supply container

, the

object being sprayed,

and

all of the solvent pails used when flushing.

Use only metal pails, which are conductive. Do not place the pail on a non-conductive surface,

such as paper or cardboard, which interrupts the grounding continuity.

6.

To maintain grounding continuity when flushing or relieving pressure

,

always hold a metal part of the gun firmly to the side of a

grounded

metal pail, then trigger the gun.

Operation

Pressure Relief Procedure

- To reduce the risk of serious bodily injury, including fluid injection, splashing fluid or solvent in the eyes or on the skin, or injury from moving

parts or electric shock, always follow this procedure whenever you shut off the sprayer, when checking or servicing any part of the spray

system, when installing, cleaning or changing spray tips, and whenever you stop spraying.

1. Lock the gun trigger safety.

2. Shut off the power supply to the pump and close any bleed-type master air valves.

3. Unlock the gun trigger safety. Hold a metal part of the gun firmly to the side of a grounded metal pall, and trigger the gun to relieve pressure.

4. Lock the gun trigger safety.

5. Open the pressure drain valve(required in system), having a container ready to catch the drainage.

6. Leave the drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely clogged or that pressure has not been fully relieved after following the steps above,

V

ERY SLOWLY loosen the tip guard retaining nut or hose end coupling and relieve pressure gradually, then loosen completely. Now clear the

tip or hose .