0

0

A

A

30/ENGINE - WORK ON INDIVIDUAL PARTS

108

19.12

Checking the valves

Info

The valve stem is chrome-hardened, and wear normally takes place in the valve guide.

200193-10

–

Check for valve retainer run-out.

Valves

Run-out on valve plate

≤

0.05

mm (

≤

0.002

in)

» If the measured value does not equal the specified value:

–

Change the valve.

400373-10

–

Check sealing seat

on the valve.

Valves

Sealing seat width, intake

1.50

mm (0.0591

in)

Valves

Sealing seat width, exhaust

2.00

mm (0.0787

in)

» If the sealing area is not in the center of the valve seat or if it differs from the

specified value:

–

Machine the valve seat.

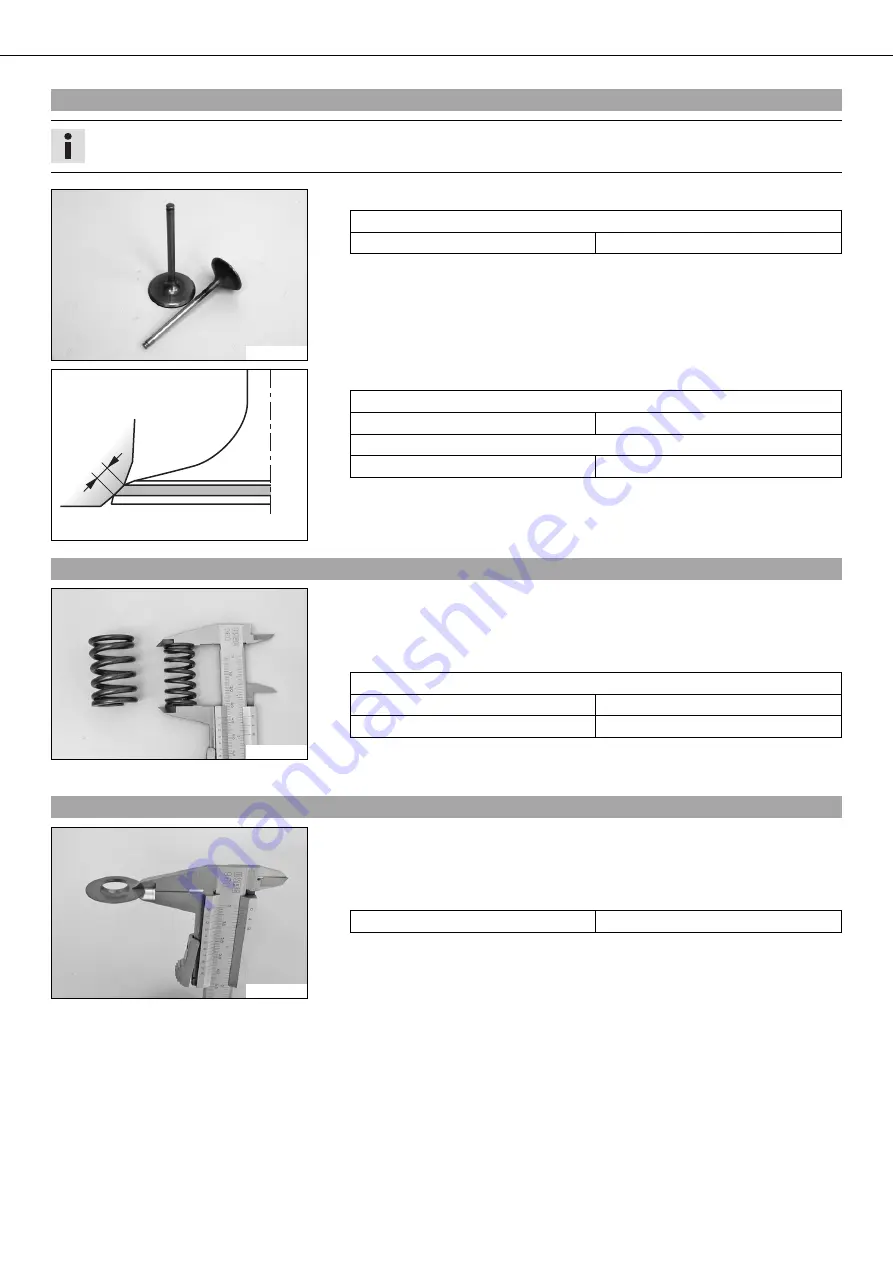

19.13

Checking the valve springs

600280-01

–

Check the valve springs for breakage and wear (visual check).

» If the valve spring is broken or worn:

–

Change the valve spring.

–

Measure the valve spring length.

Valve springs

Minimum length of outside spring

39.20

mm (1.5433

in)

Minimum length of inside spring

36.45

mm (1.435

in)

» If the measured value does not equal the specified value:

–

Change the valve spring.

19.14

Checking the lower valve spring retainer

600281-01

–

Check the lower valve spring retainer for breakage and wear (visual check).

» If the lower valve spring retainer is broken or worn:

–

Change the valve spring retainer.

–

Measure the thickness of the lower valve spring retainers.

Lower valve spring retainer - strength

0.4… 0.5

mm (0.016… 0.02

in)

» If the measured value does not equal the specified value:

–

Change the valve spring retainer.