31/CARBURETOR

153

700066-10

–

Connect the positive wire of the multimeter to the yellow

(ye) cable and the

ground wire to the black

(bl) cable of the connector of throttle valve sensor

TPS

.

–

Measure the variable resistance

R

var

of the throttle valve sensor.

Info

The throttle slide must be in the neutral position.

–

Loosen screw

. Set throttle valve sensor

TPS

by turning it to the calculated

value.

–

Tighten screw

.

Specification

Screw, throttle valve sensor

M5

3.5

Nm

(2.58

lbf

ft)

–

Check the variable resistance

R

var

of the throttle valve sensor again.

» If the measured value is not equal to the calculated value:

–

Repeat the adjustment procedure.

–

Install the carburetor. (

21.15

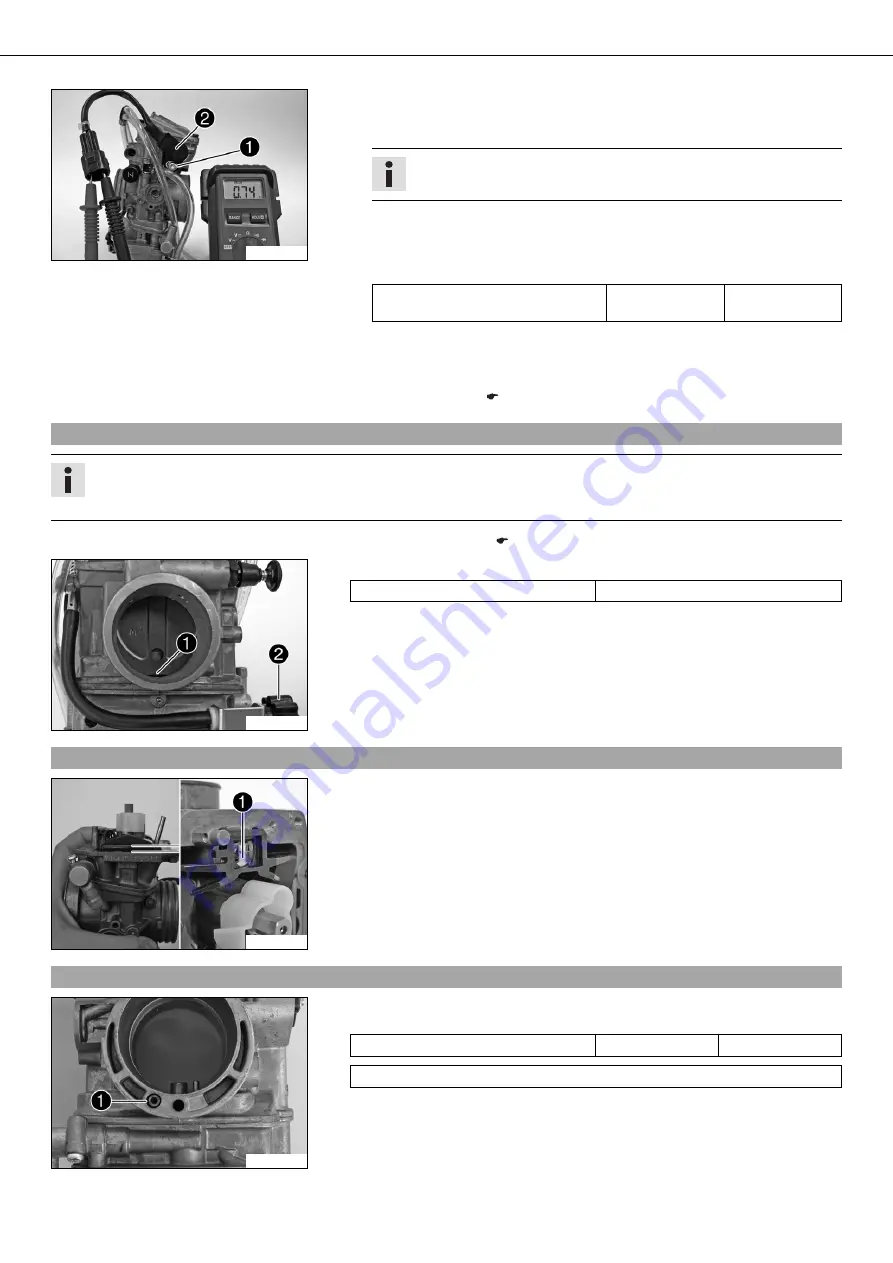

Checking/adjusting the throttle slide opening

Info

The basic setting of the throttle slide controls the time at which injection begins at the accelerator pump and the basic setting

of the throttle valve sensor.

–

Remove the carburetor. (

700062-10

–

Check the throttle slide opening using a wire or a drill shank.

Throttle slide opening

1

mm (0.04

in)

» If the throttle slide opening does not equal the specified value:

–

Adjust the throttle slide opening with adjusting screw

.

21.16

Checking/adjusting the float level

700061-10

–

Hold the carburetor at a slant, securing the pin against falling out of the float.

–

Hold the carburetor at a slant so that the float lies against the float needle valve

but does not press it together.

» In this position, if the edge on the float is not parallel to the sealing area of the

float chamber:

–

Adjust the float level by bending float lever

.

21.17

Assembling the carburetor

700049-11

–

Mount and tighten idle air jet

.

Specification

Idle air jet

M4,5x0.75

2

Nm (1.5

lbf

ft)

Idle air jet

(100)