4

SERIAL NUMBERS

8

4.1

Chassis number

401945-10

The chassis number

is stamped on the steering head on the right.

4.2

Type label

101973-10

The type label

is located on the right side of the frame.

4.3

Engine number

401949-10

The engine number

is stamped on the left side of the engine under the engine

sprocket.

4.4

Key number

100179-10

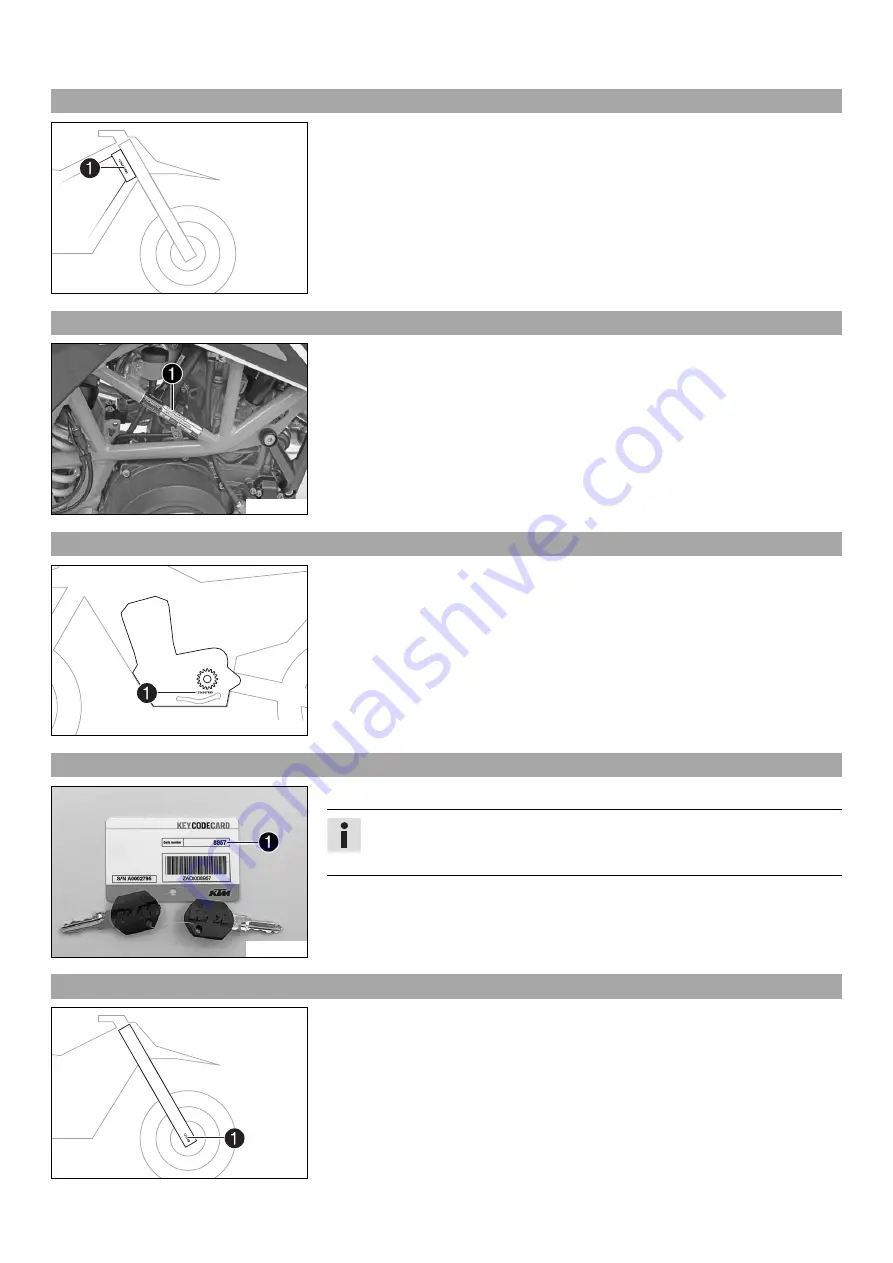

The key number

can be found on the

KEYCODECARD

.

Info

You need the key number to order a spare key. Keep the

KEYCODECARD

in a safe

place.

4.5

Fork part number

401947-10

The fork part number

is stamped on the inner side of the fork stub.