16

ENGINE

126

Info

If the bearings are not firmly seated after cooling, it is likely that they will

rotate in the engine case when warm. In this case, the engine case must be

renewed.

–

Position all bearing locks. Mount and tighten the screws.

Guideline

Locking screw for bearing

M5

6 Nm

(4.4 lbf ft)

Loctite

®

243™

–

Mount and tighten the oil jet

.

Guideline

Oil jet, piston cooling

M6x0.75

4 Nm

(3 lbf ft)

Loctite

®

243™

–

Mount and tighten the oil jet

.

Guideline

Oil nozzle for conrod bear-

ing lubrication

M4

2 Nm

(1.5 lbf ft)

Loctite

®

243™

–

Blow compressed air through all oil channels and check that they are clear.

–

Position the cover plate

. Mount and tighten the screws.

Guideline

Screw, cover plate for oil return line

M5

6 Nm (4.4 lbf ft)

–

Reinstall the dowels.

16.4.2

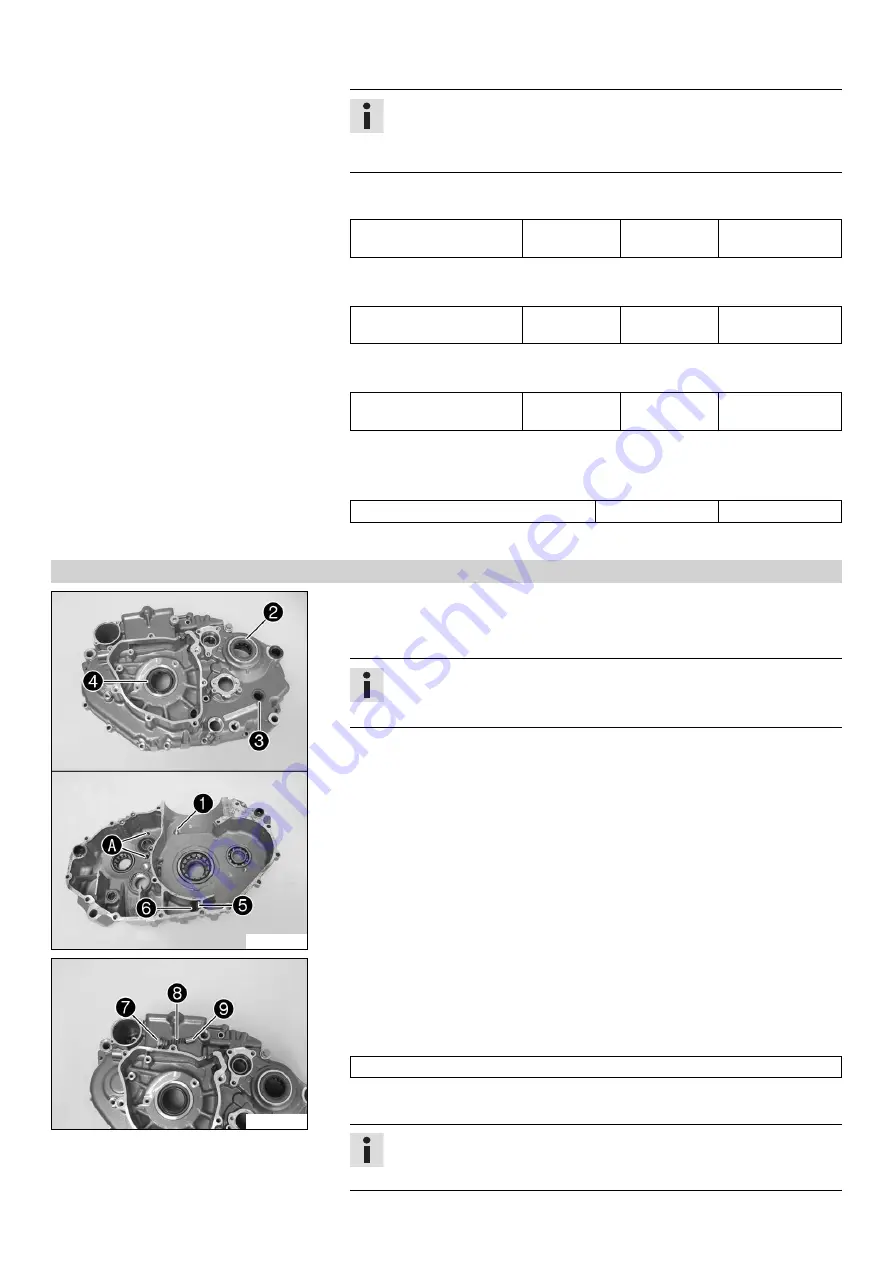

Work on the left section of the engine case

305646-10

–

Remove all dowels.

–

Remove oil jet

.

–

Remove the shaft seal ring of countershaft

and shift shaft

.

Info

The shaft seal ring

of the crankshaft cannot be removed before the

crankshaft bearing.

–

Screw off the membrane support plate

and remove it together with

membrane

.

–

Remove screw

with the washer.

305647-10

–

Remove screw plug

and take pressure spring

with piston valve

out of

the drill hole.

–

Remove any sealing mass remnants and clean the engine case section thoroughly.

–

Warm the engine case section in an oven.

Guideline

150 °C (302 °F)

–

Knock the engine case section against a level wooden plate. This will cause the

bearings to drop out of the bearing seats.

Info

Any bearings that remain in the engine case section must be removed using

a suitable tool.