KTR-STOP

®

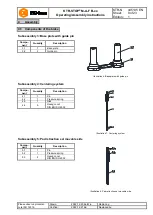

M-A-F B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445145 EN

1 of 23

1

Please observe protection

note ISO 16016.

Drawn:

2022-12-20 Ka/Wie

Replacing:

Verified:

2022-12-21 Ka

Replaced by:

KTR-STOP

®

M-A-F B-xx

M-A-F B-xx is a brake actuated hydraulically in a floating caliper design serving

to generate a brake force on a brake disk in order to decelerate a machine's mo-

vement or stop it, respectively, or keep it at standstill.