KTR-STOP

®

YAW M B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445120 EN

11 of 16

1

Please observe protection

note ISO 16016.

Drawn:

2019-11-18 Shg/Wie

Replacing:

---

Verified:

2019-11-22 Shg

Replaced by:

Please make sure that the connections and hoses are adapted to the brakes with regard to

pressure, flow rate, temperature and liquid.

Moreover, you have to use flexible hydraulic hoses in order to not limit the motions of the

brake.

Any hoses which are located close to mobile components should be secured or coated ac-

cordingly.

Before start-up and after each operation on the brake the hydraulic system has to be gene-

rally vented.

Repeat venting the brake several times a year, since any air in the hydraulic system may

affect the operation of the brake and the plant.

!

Please make sure that there is sufficient liquid in the hydraulic system during and after the

venting process (recommendation of liquid, see chapter 4.8).

•

Switch on the hydraulic system for a short while to make sure that the brake is rinsed with hydraulic oil. Repeat

this process until a stream of clean oil dissipates from the miniature measuring hose.

•

Remove the miniature measuring hose.

If the miniature measuring coupling is removed as well, the screw plug (component 1.6)

needs to be screwed in the venting hole (see illustrations 9 to 12).

•

Dispose of the hydraulic oil of the collection container as per chapter 5.

•

The active brake described in here does not require any gap to release the brake or brake pads, respectively.

•

Put some pressure on the hydraulic system. This will allow the brake pads to fit onto the brake disk.

!

The hydraulic system must never be operated at a higher pressure than the figures spe-

cified in the type plate of the brake or table 1. If any figures or types/sizes are changed,

please consult with KTR.

!

Never keep your fingers between brake disk and brake when applying the brake in order to

prevent serious injuries of your hands.

Before every maintenance operation make sure that the brake is fully secured against acti-

vating.

•

The brake pads have to be ground in on the surface of the brake disk to achieve the nominal coefficient of

friction.

4

Assembly

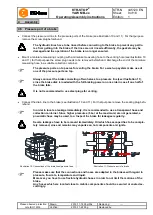

4.6 Pressure port of several brakes

4.7 Start-up of the brake