KTR-STOP

®

YAW M B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445120 EN

13 of 16

1

Please observe protection

note ISO 16016.

Drawn:

2019-11-18 Shg/Wie

Replacing:

---

Verified:

2019-11-22 Shg

Replaced by:

•

Release the pressure fully from the hydraulic system.

!

Make sure that the entire brake system is depressurized.

STOP

Parts released or falling down may cause injury to persons or damage on the machine.

Secure the components before disassembly.

•

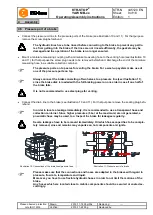

Remove the highest located screw plug (component 1.6) from the venting hole (see illustrations 10 to 13).

•

Drain the hydraulic oil completely from the brake.

•

Dispose of the hydraulic oil as per chapter 5.

•

Disconnect the drain and pressure oil line from the brake.

•

Screw the screw plugs (component 1.6) in all pressure ports or venting holes (see illustration 10 to 13).

•

Remove the 8-off screws (M27) serving for fixing the brake to the connection plate.

•

Take out the brake.

•

Depending on the thickness of brake disk

Remove the distance plate after having taking out the first half of the brake.

•

Remove the 2-off cap screws (M10) serving for fixing the second half of brake to the connection plate.

•

Take out the second half of brake (component 1).

There are one resp. two gaskets between the two brake halves. Make sure not to lose them.

In respect of environmental protection we would ask you to dispose of the products on termination of their service

life in accordance with the legal regulations and standards that apply, respectively.

•

Metal or brake pads, respectively

Brake pads and any other metal parts have to be cleaned and disposed of by scrap metal.

•

Gaskets

Gaskets can be disposed of by residual waste.

•

Hydraulic oil

Hydraulic oils have to be collected in suitable tanks and disposed of by a waste disposal company.

4

Assembly

4.9 Disassembly of the brake

5

Disposal