KTR-STOP

®

YAW M B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445120 EN

15 of 16

1

Please observe protection

note ISO 16016.

Drawn:

2019-11-18 Shg/Wie

Replacing:

---

Verified:

2019-11-22 Shg

Replaced by:

When removing the gaskets and scrapers make sure that the keyways in the housing are

not damaged.

•

The components have to be cleaned from dirt, grease and corrosion protection. The components can easily be

cleaned by means of solvents. Afterwards dry the components.

!

Observe the manufacturer’s instructions regarding the use of solvents.

•

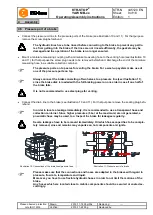

Insert gaskets (component 1.4 and 1.5) and scrapers (component 1.3) into the housing (component 1.1). For

that purpose the components may be heart-shaped (see illustration 14).

!

The gaskets and scrapers have to be installed in the right direction (see illustration 15).

With a reassembly of the brake piston basically new gaskets and scrapers have to be used,

since their operativeness is no longer ensured due to wear and damages.

•

Grease the gaskets and scrapers with hydraulic oil (see illustration 15).

!

Oils and greases containing molybdenum disulphite or zinc sulphite additives must not be

used.

Illustration 14: Assembly of O-ring, support ring

and scraper

Illustration 15

!

Inspect the surfaces of the brake pistons and the holes of the housing to make sure that

they are neither scratched nor damaged, since the surfaces are either ground or polished.

Such kind of damages may cause earlier wear on the gaskets and scrapers and generate

leakages.

•

Insert the brake pistons (component 1.2) in the housing (component 1.1) and press them against a stop.

•

Mount the (new) brake pad. Insert the brake pad into the housing as deep as possible. Compress the brake

pad and brake piston manually.

•

Repeat chapters 4.2 to 4.7.

6

Maintenance

6.2 Maintenance of the brake / replacement of single parts