RADEX

®

-N

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

47110 EN

15 of 31

24

Please observe protection

note ISO 16016.

Drawn:

2019-07-23 Pz/Wb

Replacing:

KTR-N dated 2018-07-17

Verified:

2019-07-26 Pz

Replaced by:

!

The stiffness and dimensions of the shafts (here specifically hollow shafts) have to be

selected in a way that sufficient safety against plastic deformation is provided for (if

necessary, consult with company KTR).

We recommend to inspect bores and shafts for dimensional accuracy before assembly.

!

With the assembly please make sure that the distance dimension E (see table 1 and 2) is

observed so that the coupling components are not in contact with each other during the

operation.

Disregarding this advice may cause damage to the coupling.

If used in potentially explosive atmospheres the setscrews to fasten the hubs as well as all

screw connections must be secured against working loose additionally, e. g. conglutinating

with Loctite (average strength).

For axial alignment of the coupling the distance dimension E (see table 1 and 2) is decisive. In order to set the

right dimension E you should proceed as follows:

•

Clean and degrease the hub bores and shafts, afterwards lubricate with a thin-fluid oil (e. g. Castrol 4 in 1 or

Klüber Quietsch-Ex).

!

Oils and greases containing molybdenum disulfide or other high-pressure additives as well

as internal lubricants must not be used.

•

Lightly unscrew the clamping screws and pull the clamping ring from the clamping ring hub only marginally to

make sure that the clamping ring is fitted loosely.

•

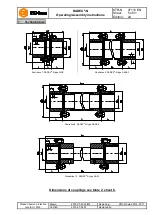

Mount the clamping ring hubs on the shaft of driving and driven side (see illustration 18).

•

The internal sides of the clamping ring hubs must be flush with the front sides of the shafts (see illustration 18).

•

Shift the power packs in axial direction until the distance dimension E is achieved (see table 1 or 2).

•

Tighten the clamping screws evenly crosswise at first to 1/3 and afterwards 2/3 of the full tightening torque

(see table 8). Afterwards tighten the clamping screws crosswise at the full tightening torque. The process

needs to be repeated until the tightening torque has been achieved with all screws.

Illustration 18: Assembly of clamping ring hubs

4

Assembly

4.4 Assembly/disassembly of clamping ring hubs