ROTEX

®

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

40210 EN

14 of 22

22

Please observe protection

note ISO 16016.

Drawn:

2017-09-06 Pz/Bru

Replacing:

KTR-N dated 2017-01-02

Verified:

2017-09-06 Pz

Replaced by:

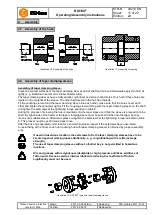

Before start-up of the coupling, please inspect the tightening of the setscrews in the hubs, the alignment and the

distance dimension E and adjust, if necessary, and also inspect all screw connections for the tightening torques

specified, dependent on the type of coupling.

If used in hazardous locations the setscrews to fasten the hubs as well as all screw

connections must be secured against working loose additionally, e. g. conglutinating with

Loctite (average strength).

Finally the coupling protection against accidental contact must be fitted.

The cover must be electrically conductive and included in the equipotential bonding. Bellhousings (magnesium

share below 7.5 %) made of aluminium and damping rings (NBR) can be used as connecting element between

pump and electric motor. The cover may only be taken off with standstill of the unit.

During operation of the coupling, please pay attention to

different operating noise

vibrations occurring.

If the couplings are used in locations subject to dust explosion and in mining the user must

make sure that there is no accumulation of dust in a dangerous volume between the cover

and the coupling. The coupling must not operate in an accumulation of dust.

For covers with unlocked openings on the top face no light metals must be used if the

couplings are used as equipment of equipment group ll (

if possible, from stainless steel

).

If the couplings are used in mining (equipment group l M2), the cover must not be made of

light metal. In addition, it must be resistant to higher mechanical loads than if it is used as

equipment of equipment group ll.

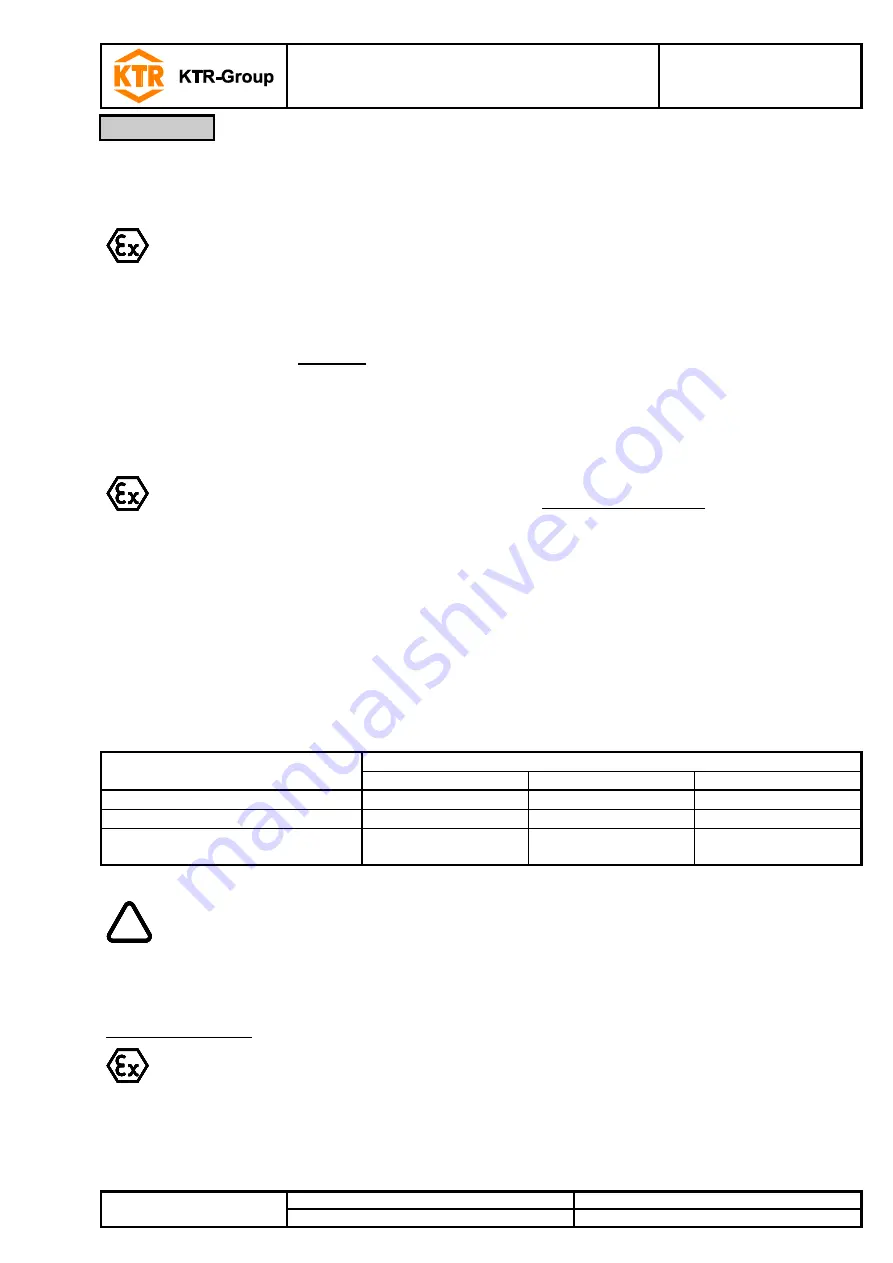

The minimum distan

ce „Sr“ between the protective device and the rotating parts must at least correspond to the

figures specified below.

If the protective device is used as cover, regular openings can be arranged from the point of view explosion

protection that must not exceed the following dimensions:

Openings

Cover [mm]

Top side

Lateral components

Distance „Sr“

Circular - max. diameter

4

8

10

Rectangular - max. lateral length

4

8

10

Straight or curved slot - max. lateral

length/height

not permissible

8

20

!

If you note any irregularities with the coupling during operation, the drive unit must be

switched off immediately. The cause of the breakdown must be specified by means of the

table „Breakdowns“ and, if possible, be eliminated according to the proposals. The potential

breakdowns mentioned can be hints only. To find out the cause all operating factors and

machine components must be considered.

Coating of coupling:

If coated (priming, paintings, etc.) couplings are used in hazardous locations, the requirements on

conductibility and coating thickness must be considered. In case of paintings up to 200 µm

electrostatic load does not have to be expected. Multiple coatings exceeding 200 µm are prohibited

for explosion group llC.

5

Start-up