KTR Kupplungstechnik

GmbH

D-48407 Rheine

B o W e x - E L A S T I C

®

Operating-/Assembly Instructions

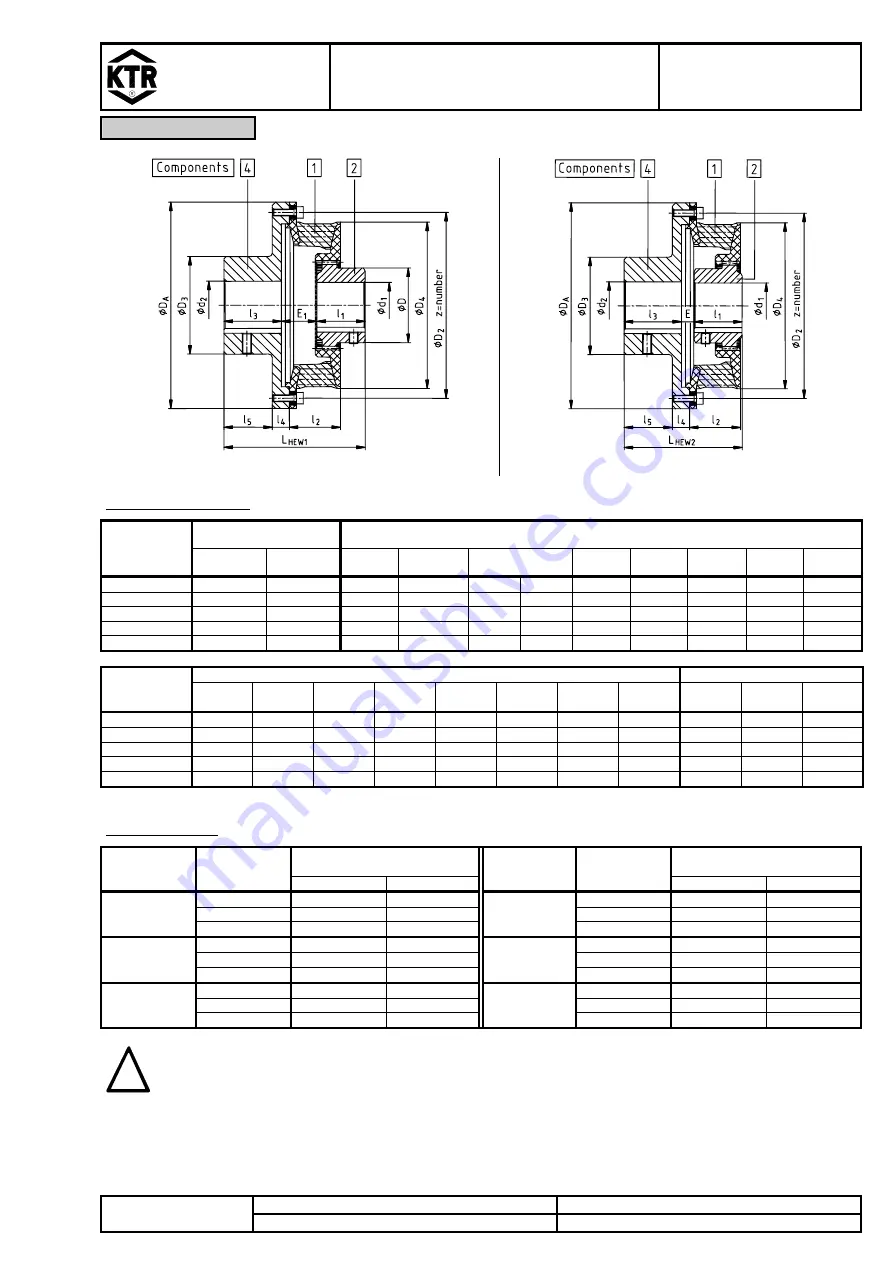

Design 065 (HEW1 and HEW2)

KTR-N

sheet:

edition:

40114 E

2

4

Gezeichnet:

08.04.04 Sha/Hk

Ersatz für:

KTR-N vom 01.12.99

Schutzvermerk

ISO 16016 beachten.

Geprüft:

08.04.04 Sha

Ersetzt durch:

1 Technical Data

picture 1: BoWex-ELASTIC

®

design HEW1

picture 2: BoWex-ELASTIC

®

design HEW2

Table 1: dimensions

finish bore [mm]

dimensions [mm]

BoWex-

ELASTIC

®

size

d

1 max.

d

2 max.

D D

2

z

x

M

D

3

D

4

D

A

l

1

l

2

42

HEW

48

50

65 162 6 M6 85 146 180 42 45

48

HEW

48

55

68 180 8 M6 92 164 200 50 45

65

HEW

65

75

96 224 8 M8 125 204 245 55 55

80

HEW

85

85

124 295,27 8 M10 130 266 318 90 70

G 80 HEW

85

95

124

333,4

8

M10

145

302

356

90

80

dimensions [mm]

thread for setscrews

BoWex-

ELASTIC

®

size

l

3

l

4

l

5

l

7

E E

1

L

HEW1

L

HEW2

G

t

T

A

[Nm]

42

HEW 50 15 42 50 4 32 132

104 M8 10 10

48

HEW 55 17 45 50 4 32 137

109 M8 10 10

65 HEW

75

28

63

70

5

42

187

150

M10

15

1)

17

80

HEW 80 17 70 75 5 45 215

160

M10 20 17

G 80 HEW

90

22

78

90

5

55

235

185

M10

20

17

1) hub length 55 mm t = 15mm; hub length 70 mm t = 20mm.

Table 2: Torque

torque

[Nm]

torque

[Nm]

BoWex-

ELASTIC

®

size

elastomer

hardness

[Shore A]

T

KN

T

K max.

BoWex-

ELASTIC

®

size

elastomer

hardness

[Shore A]

T

KN

T

K max.

40 130 390

40 750

2250

50 150 450

50 950

2850

42 HEW

65 180 540

80 HEW

65 1200

3600

40 200 600

40 1250

3750

50 230 690

50 1600

4800

48 HEW

65 280 840

G 80 HEW

65 2000

6000

40

350

1050

50

400

1200

65 HEW

65 500

1500

!

C A U T I O N !

For a continuous and troublefree operation of the coupling it must be designed according to

the selection instructions (according to DIN 740 part 2) for the particular application

(see BoWex-ELASTIC

®

-catalogue).

If the operating conditions (performance, speed, changes at engine and machine) change,

the coupling selection must be checked again.