KTR Kupplungstechnik

GmbH

D-48407 Rheine

B o W e x - E L A S T I C

®

Operating-/Assembly Instructions

Design 065 (HEW1 and HEW2)

KTR-N

sheet:

edition:

40114 E

5

4

Gezeichnet:

08.04.04 Sha/Hk

Ersatz für:

KTR-N vom 01.12.99

Schutzvermerk

ISO 16016 beachten.

Geprüft:

08.04.04 Sha

Ersetzt durch:

4 Assembly

4.2 Hint regarding the finish bore

STOP

D A N G E R !

The maximum permissible bore diameters d (see table 1 in

chapter 1 - Technical Data) must not be exceeded. If these

figures are disregarded, the coupling may tear. Rotating

particles may cause serious danger.

•

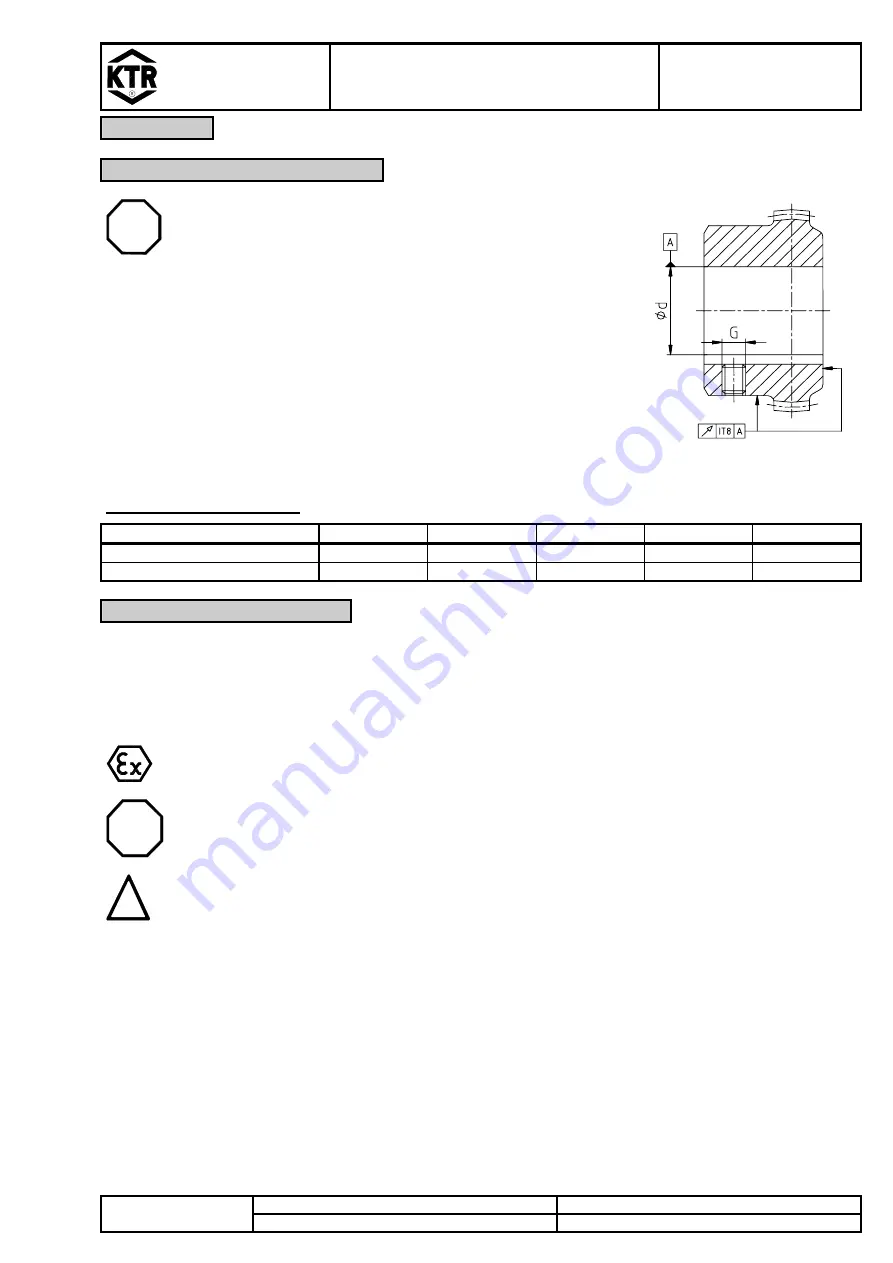

Hub-/coupling flange bores machined by the customer have to

observe concentric running or axial running, respectively (see

picture 5).

•

Please make absolutely sure to observe the figures for d

max

.

•

Carefully align the hub and the coupling flange when the finish

bores are brought in.

•

Please provide for a setscrew or an end plate for the axial

fastening of the hub and the coupling flange.

picture 5: concentric running

and axial running

Table 3: Setscrews DIN 916

BoWex-ELASTIC

®

size

42 HEW

48 HEW

65 HEW

80 HEW

G 80 HEW

screw size

M8

M8

M10

M10

M10

tightening torque T

A

[Nm]

10 10 17 17 17

4.3 Assembly of the Coupling

A T T E N T I O N !

We recommend to check bores, shaft, keyway and feather key for dimensional accuracy

before assembly.

Heating the hub and coupling flange slightly (approx. 80 °C) allows for an easier installation onto the shaft.

P R E C A U T I O N !

Please pay attention to the danger of ignition in hazardous areas.

STOP

D A N G E R !

Touching the heated parts causes burns.

We would recommend to wear safety gloves.

!

C A U T I O N !

For the assembly please make sure that the distance dimension E (see table 1) is kept to

ensure that the elastomer part can be moved axially.

Disregarding this hint may cause damage on the coupling.

•

Assemble the hub and the coupling flange onto the shafts.

•

Safe the coupling hub and the coupling flange by tightening the setscrews DIN 916 with cup point or by an end

disk.

•

Put the elastomer part in front of the flange hub.

•

First hand-screw the parts.

•

Use screws of the property class 8.8 or higher.

•

Tighten the screws with a suitable dynamometric key up to the tightening torques T

A

indicated in table 4.