KTR Kupplungstechnik

GmbH

D-48407 Rheine

B o W e x - E L A S T I C

®

Operating-/Assembly Instructions

Design 065 (HEW1 and HEW2)

KTR-N

sheet:

edition:

40114 E

9

4

Gezeichnet:

08.04.04 Sha/Hk

Ersatz für:

KTR-N vom 01.12.99

Schutzvermerk

ISO 16016 beachten.

Geprüft:

08.04.04 Sha

Ersetzt durch:

5 Enclosure A

Hints and instructions regarding the use in

hazardous areas

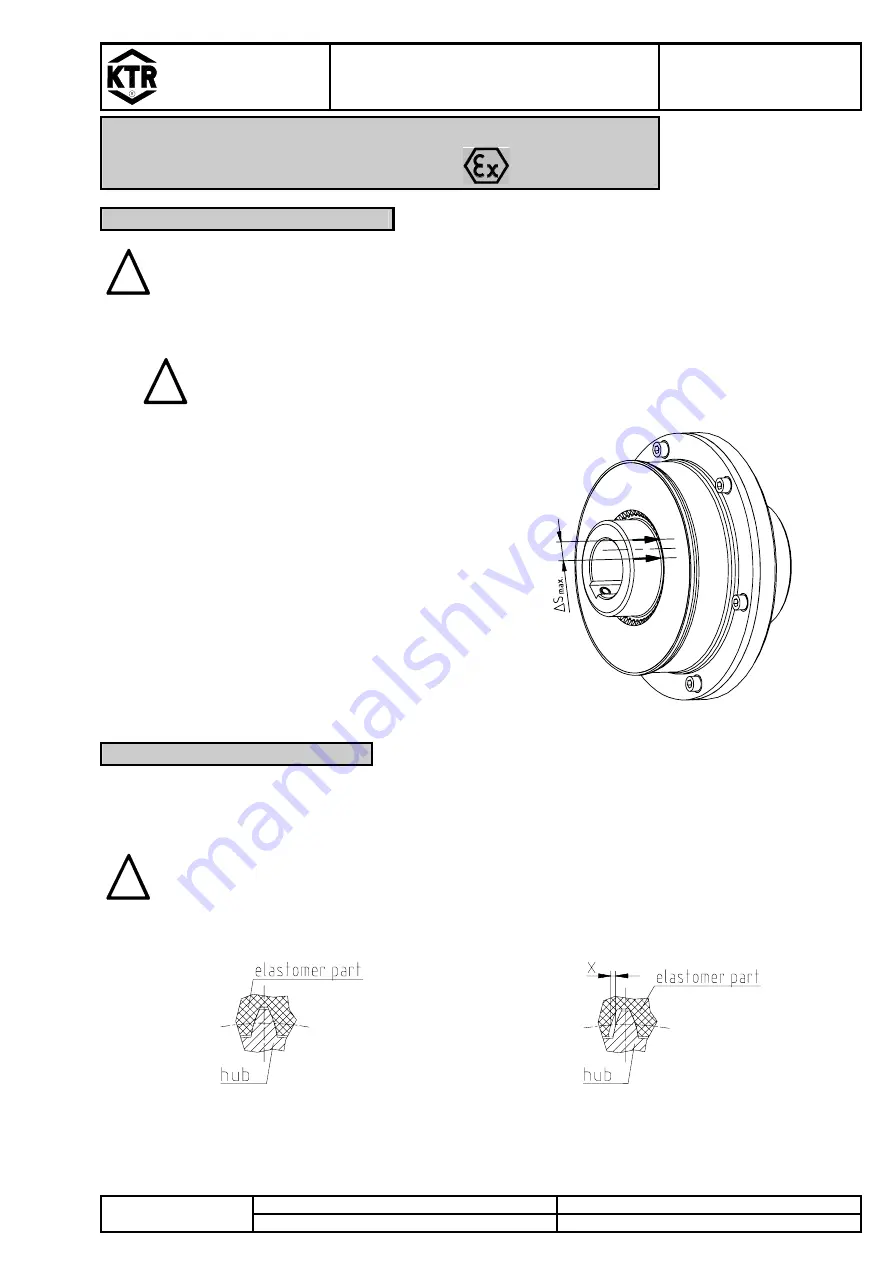

5.2 checking of torsional backlash

!

C A U T I O N !

To check the torsional backlash the turned off drive aggregate must be secured against

unintended turning on.

•

Turn the hub in opposite direction to the direction of drive.

!

C A U T I O N !

Here the elastomer part may not be axially displaced from its wear position.

•

Mark elastomer part and hub (see picture 9).

•

Turn the hub in the direction of drive and measure

the torsional backlash

∆

S

max

.

•

When reaching the torsional backlash

∆

S

max

the

elastomer part must be exchanged.

picture 9: marking of the hub and the elastomer part

5.3 Approximate values of wear

If the torsional backlash is

≥

∆

S

max.

[mm] / friction

≥

X

max.

[mm], the elastomer part must be exchanged.

The reaching of the exchange values depends on the operating conditions and the existing operating parameters.

!

C A U T I O N !

In order to ensure a long lifetime of the coupling and to avoid dangers regarding the use in

hazardous areas, the shaft ends must be accurately aligned.

Please absolutely observe the displacement figures indicated (see table 5). If the figures are

exceeded, the coupling is damaged.

picture 10: elastomer part in new condition

picture 11: wear of elastomer part