KTR Kupplungstechnik

GmbH

D-48407 Rheine

POLY

Operating-/Assembly Instructions

KTR-N

sheet:

edition:

49610 EN

17 of 24

9

Gezeichnet: 11.03.10

Pz/Bru

Ersatz für:

KTR-N vom 25.04.07

Schutzvermerk

ISO 16016 beachten. Geprüft:

16.03.10 Pz

Ersetzt durch:

5 Enclosure A

Hints and Instructions Regarding the Use in

Hazardous Areas

5.2 Control Intervals for Couplings in

Hazardous Areas

explosion group

control intervals

3G

3D

For couplings which are classified in category 3G or 3D the operating and assembly

instructions that are usual for standard operation apply. During the standard operation

which has to be subject to the analysis of danger of ignition the couplings are free from any

ignition source. Merely the temperature increase produced by proper heating and

depending on the coupling type has to be considered:

for POLY:

Δ

T = 20 K

II 2GD c IIB

T4, T5, T6

The torsional backlash of the coupling (see chapter 5.3) according to Guideline 94/9/EC

(ATEX 95) must only be controlled if a friction of the elastomer elements (part 2) and

consequently a machine down-time of the drive leads to explosion hazard.

A preventive checking of torsional backlash is recommended.

A checking of the circumferential backlash and a visual check of the elastomer elements

must be effected after 3,000 operating hours for the first time, after 6 months at the latest.

Except for centered, stiff connecting flanges (e. g. bellhousings).

If you note an unconsiderable or no wear at the elastomer elements after this first

inspection, the further inspections can be effected, in case of the same operating

parameters, respectively after 6,000 operating hours or after 18 months at the latest.

If you note a considerable wear during the first inspection, so that a change of the

elastomer elements would be recommended, please find out the cause according to the

table „Breakdowns“, as far as possible.

The maintenance intervals must be adjusted according to the changed operating

parameters.

II 2GD c IIC

T4, T5, T6

The torsional backlash of the coupling (see chapter 5.3) according to Guideline 94/9/EC

(ATEX 95) must only be controlled if a friction of the elastomer elements (part 2) and

consequently a machine down-time of the drive leads to explosion hazard.

A preventive checking of torsional backlash is recommended.

A checking of the circumferential backlash and a visual check of the elastomer elements

must be effected after 2,000 operating hours for the first time, after 3 months at the latest.

Except for centered, stiff connecting flanges (e. g. bellhousings).

If you note an unconsiderable or no wear at the elastomer elements after this first

inspection, the further inspections can be effected, in case of the same operating

parameters, respectively after 4,000 operating hours or after 12 months at the latest.

If you note a considerable wear during the first inspection, so that a change of the

elastomer elements would be recommended, please find out the cause according to the

table „Breakdowns“, as far as possible.

The maintenance intervals must be adjusted according to the changed operating

parameters.

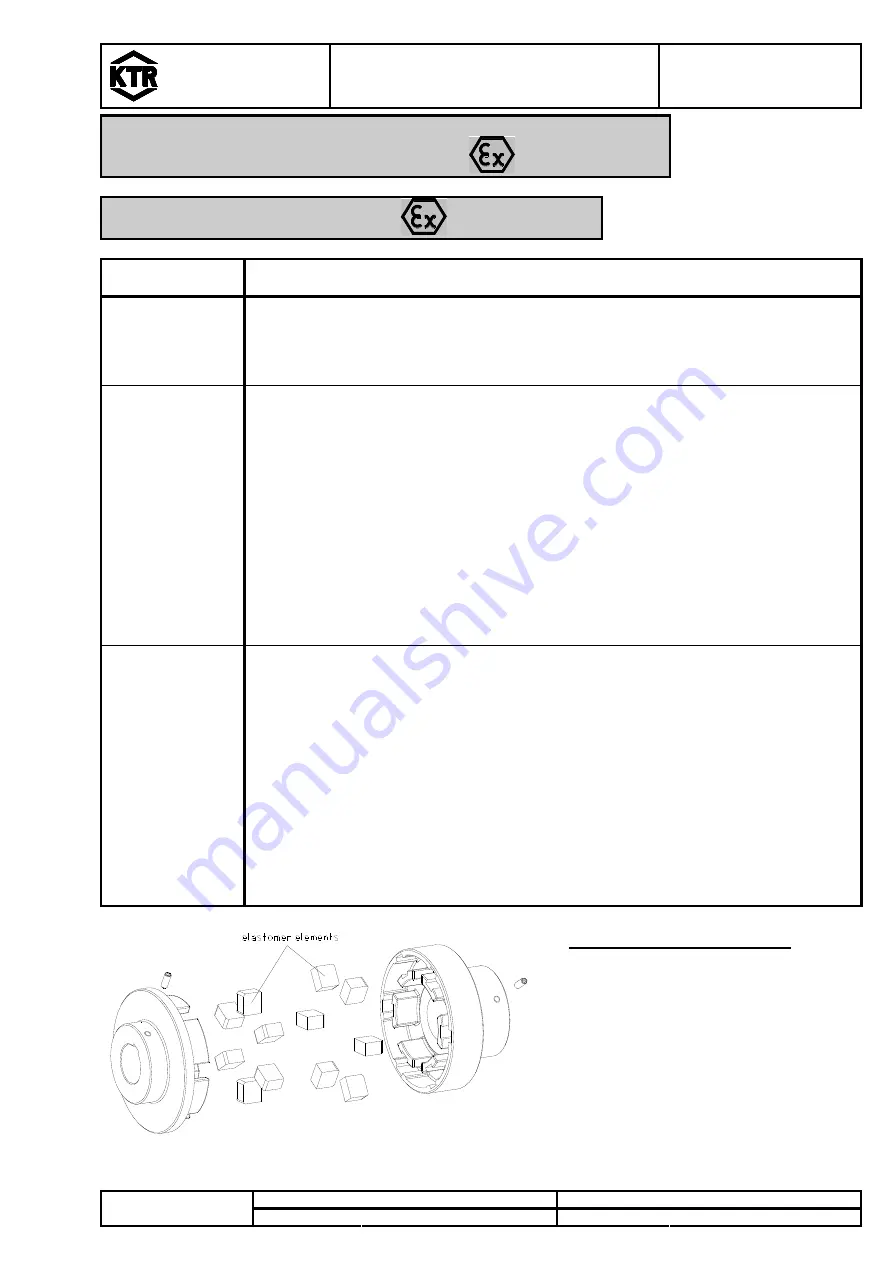

picture 21: POLY type PKZ

Checking of torsional backlash

Here the backlash between coupling cams

and the elastomer elements must be

checked by reverse backlash.

The friction/wear may be 20 % of the

original thickness of the elastomer element

before exchanging the elastomer

elements. After having reached the limit of

wear

Δ

s

max.

the elastomer elements must

be exchanged immediately, irrespective of

the inspection intervals.