SKY PRO 1800 FORCED CIRCULATION MANUAL

C

C

C

30

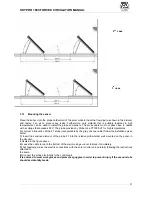

3.18 Heat-transfer fluid

The heat-transfer fluid is an essential element of the solar collectors as it transports the heat received from

the sun to the storage systems and heat exchange that has been chosen to be used. There are various

types: air, water or other liquids. Its main features must be the following: resistance to variation in

temperature (from freezing point up to boiling point),

•

protection against corrosion,

•

it cannot be excessively viscous,

•

it is not compatible with zinc (therefore the hydraulic connections between the collectors and the

cylinder cannot be galvanised).

The glycol supplied by Kloben is the propilene-type FS, it is totally pre-mixed and ready for use. It

guarantees protection from freezing to -20°C. It contains corrosion inhibitors that guarantee efficient

protection and duration of the copper pipes, (and all other metals and alloys used) in particular from

corrosion and deposits.

In order to maintain the protective features of the Kloben anti-freeze unaltered, it must not be mixed with

other heat-transfer fluids and anti-freeze or diluited with water. Any top-up owing to the loss of fluid must be

compensated exclusively with Kloben anti-freeze. Before loading always check that there is no water in the

circuit.

The use of deposited metals is advised for soldering. For welding points the use of deposited metals is

recommended for brazing in silver and copper.

Kloben anti-freeze does not attack the sealing materials normally used in solar systems. However, attention

must be paid that all sealing materials are resistant to the maximum temperature of the heat-transfer fluid.

Failure to comply with these checks can lead to the warranty fo the solar collector becoming void.

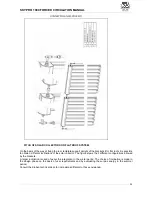

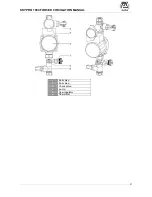

3.19 Loading the system

Filling the system via the solar station.

1.

Before starting the filling process, verify that the panels have been covered for at least 5 hours. It is

strongly recommended to keep the solar collector always covered from the moment when panels is

installed to when the system is commissioned.

2.

Connect the flow pipe of the filling pump to the ball valve (

1

).

3.

Connect the return pipe of the filling pump to the ball valve (

2

).

4.

Open the ball valves (

1

and

2

).

5.

Close the check valve (

3

) (turn clockwise).

6.

Switch the filling pump on for the anti-freeze agent to flow in an anti-clockwise direction with respect

to normal operation.

7.

Should there be a diverter valve on the solar line, ensure this is open (manual) so as to allow the

anti-freeze agent to flow in both circuits. Upon completion of this process, bring the valve back to its

original position (automatic).

8.

Let the pump run for as long as is necessary for the system to be perfectly deaerated.

9.

Open and quickly close the check valve

(3)

for a couple of seconds.

10.

Upon completion of this process, leave the valve in the “open position”.

11.

Close the ball valve (

2

).

12.

Bring the system’s pressure up to 3 bar (the pressure is viewed on the pressure gauge).

13.

Close the ball valve (

1

).

14.

Switch the filling pump off.

15.

Switch the solar control box on and verify that its settings and operation are correct.

16.

Set the flow regulator to the correct value.

17.

Uncover the previously covered panels.

Summary of Contents for SKY PRO 10 CPC 58

Page 1: ...TECHNICAL MANUAL SOLAR COLLECTORS SKY PRO 1800 ...

Page 2: ......

Page 47: ...SKY PRO 1800 FORCED CIRCULATION MANUAL C C 47 ...

Page 49: ......