Section 1: Assembly & Set-up

AP-CC30 Concrete Claw 328-160MK

11/11/19

8

Power Machine Requirements

The Concrete Claw is designed to fit on skid steer loaders

and compact track loaders with the following minimum

requirements:

Hitch type

. . . .Skid steer type quick attach, meets ISO 24410

Maximum horsepower rating . . . . . . . . . . . . . .100 hp

WARNING

!

To avoid serious injury or death:

•

Consult your power machine’s manual for operating

capacity, lifting capacity, and operating specifications.

Exceeding rated capacities and specifications can result in

a roll-over or other serious hazard.

•

Lightweight power machines may need weight added to the

rear to maintain steering control and prevent forward

tipping or side tipping caused by a heavy front load. Consult

your power machine Operator’s Manual to determine

proper weight requirements and maximum weight

Torque Requirements

Refer to

“Torque Values Chart”

on page 21 to determine

correct torque values when tightening hardware.

Before You Start

WARNING

!

To avoid serious injury or death:

Allow only persons to operate this attachment who have fully

read and comprehended this manual, who are properly trained

to operate the attachment safely, and who are age 16 or older.

Serious injury or death can result from the failure to read,

understand, and follow instructions provided in this manual.

Make sure the intended power machine conforms to

and understand the Operator’s Manual for your Concrete

Claw. An understanding of how it works will aid in the

assembly and setup of your Concrete Claw.

Go through the

before assembling the Concrete Claw. Speed up your

assembly task and make the job safer by having all

needed parts and equipment readily at hand.

Section 1: Assembly & Set-up

Power Machine Shutdown Procedure

The following are basic power machine shutdown

procedures. Follow these procedures and any additional

shutdown procedures provided in your power machine

Operator’s Manual before leaving the operator’s seat.

1. Reduce engine speed and shut-off all power to the

attachment.

2. Park on solid, level ground and lower attachment until

it is flat on the ground or on non-concrete support

blocks.

3. If shutting down a tractor, put tractor in park or set

park brake.

4. Turn off engine, and remove switch key to prevent

unauthorized starting.

5. Relieve all hydraulic pressures.

6. If included, raise seat bar and move controls until

both lock.

7.

Wait for all components to come to a complete stop

before leaving the operator’s seat.

8. Use steps, grab-handles, and anti-slip surfaces

when stepping on and off the power machine.

Hook-up Concrete Claw

DANGER

!

To avoid serious injury or death:

A crushing hazard exists while hooking-up and unhooking the

attachment. Do not allow anyone to stand between attachment

and power machine while approaching or backing away from

the attachment. Do not operate lift and/or tilt controls while

someone is near the power machine and/or attachment.

WARNING

!

To avoid serious injury or death:

Check hitch fit-up frequently. An improper fit-up can cause the

attachment to come loose from the loader hitch plate and fall.

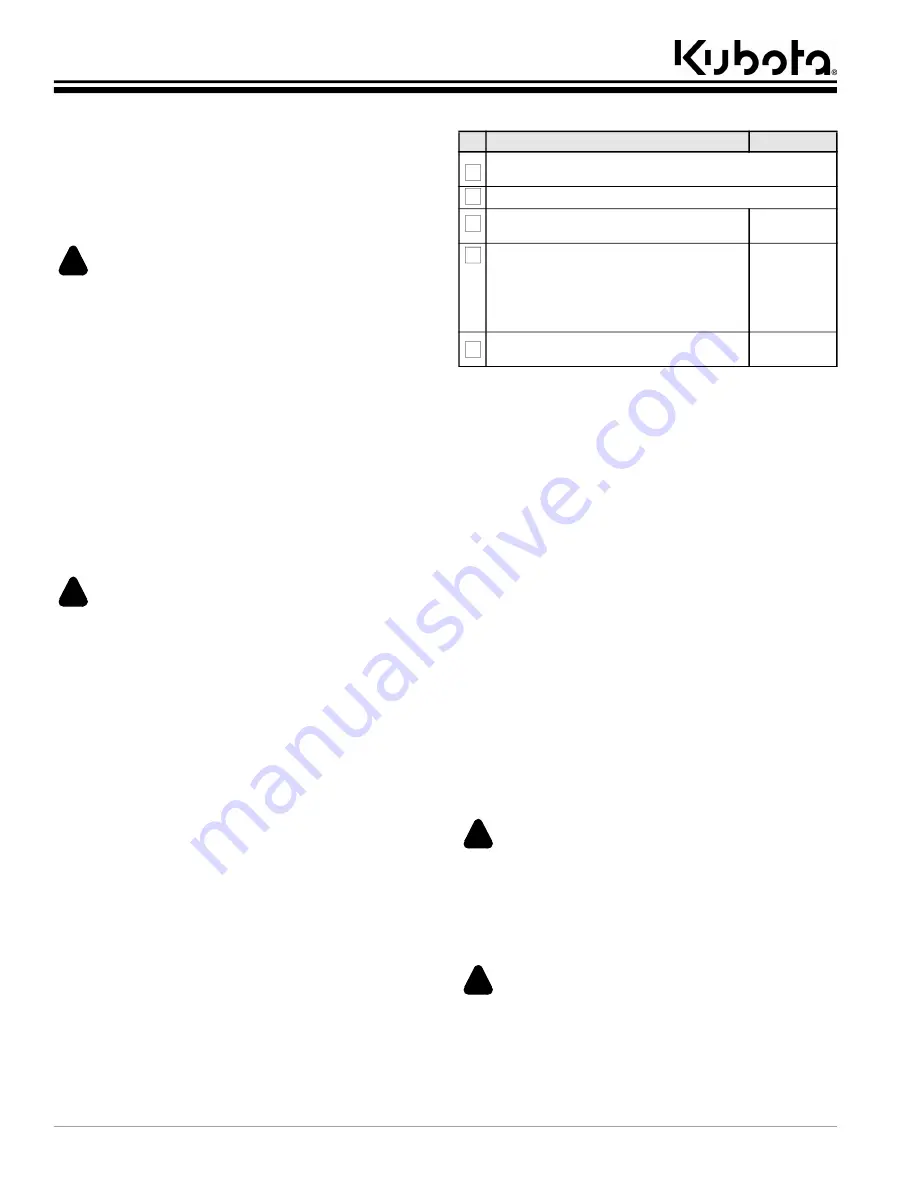

Pre-Assembly Checklist

Check

Reference

Have a forklift or loader with properly sized chains and safety

stands capable of lifting and supporting the equipment on hand.

Have a minimum of two people available during assembly.

Make sure all components are shipped with the

attachment.

Operator’s

Manual

Double check to make sure all parts and

fasteners are installed correctly.

Refer to the Parts Manual if unsure.

NOTE:

Remember location of a part or

fastener if removed. Keep parts separated.

Operator’s

Manual

328-160MK

Parts Manual

328-160PK

Make sure all safety labels are correctly

located and legible. Replace if damaged.