Section 8: Troubleshooting

12/18/19

AP-SC2560 & AP-SC2572 Skid Steer Rotary Cutter 326-836MK

39

Section 8: Troubleshooting

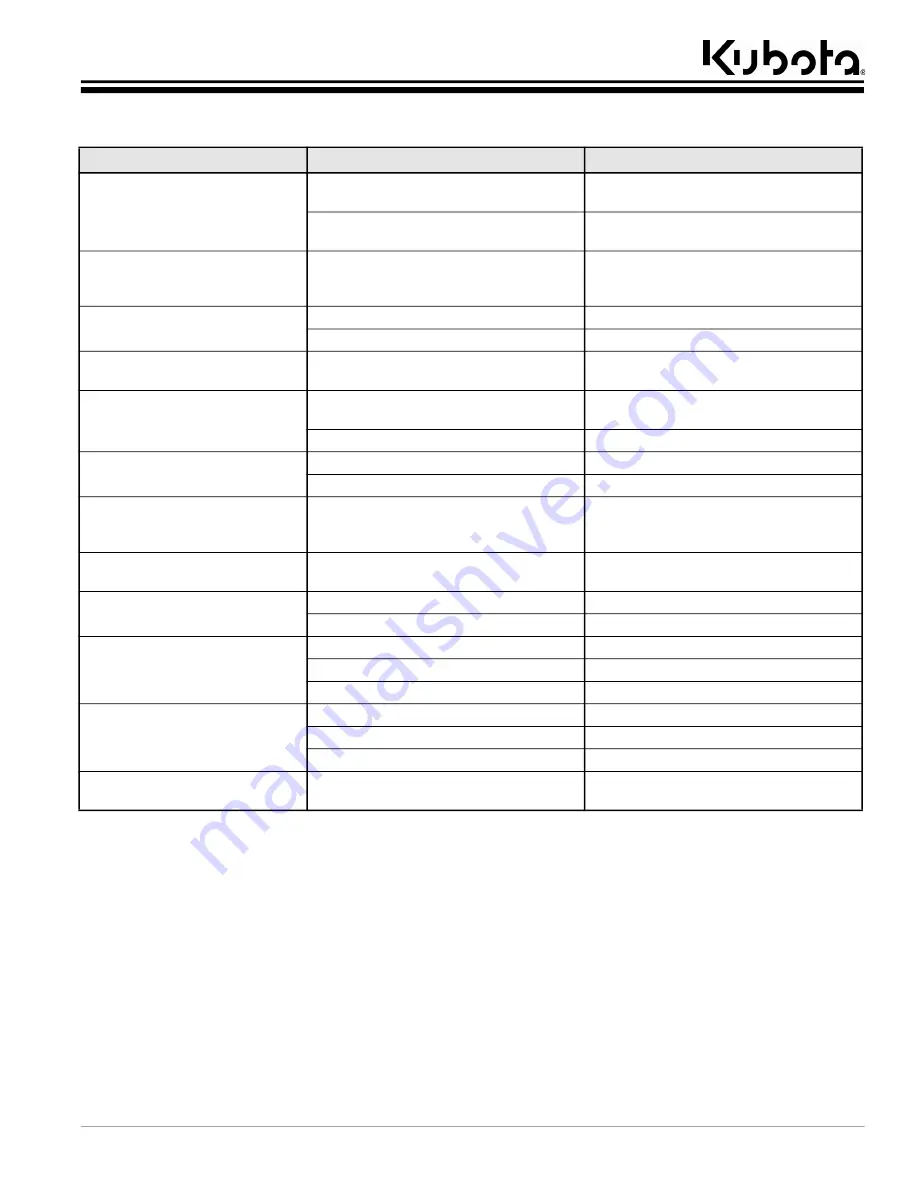

Troubleshooting Chart

Problem

Cause

Solution

Motor Oil Seal Leaking

Return line from motor has been pinched

or is collapsed.

Replace lower seal of motor. Check motor

return hose for kinks.

Case drain line is not properly connected.

Connect case drain line to the hydraulic

motor and skid steer reservoir.

Spindle Hub Seal Leaking

Seal is worn or torn.

Replace lower seal of motor and Spindle

Hub output shaft seal. Check motor return

hose for kinks.

Blades wearing excessively

Cutting on sandy ground.

Raise cutting height.

Contacting ground frequently.

Raise cutting height.

Blades coming loose

Blade bolts not tightened properly.

Use new nut and torque blade bolt nuts to

450 ft lbs.

Blade carrier becomes loose

Running loose in the past.

Replace gearbox output shaft and blade

carrier.

Blade carrier hardware not tight enough.

Tighten to specified torque.

Blade bolt holes worn

Blade hardware running loose.

Replace blades and blade bolts if worn.

Not maintaining tip speed.

Slow down to maintain tip speed.

Blades breaking

Hitting solid objects.

Thoroughly check the cutting area

BEFORE beginning to cut. Be alert during

cutting.

Blade Carrier bent

Hitting solid objects.

Avoid solid objects/Be alert. Replace blade

carrier.

Gauge wheel support failing

Lowering too fast.

Adjust rate of drop.

Hitting objects when turning.

Reduce speed on turns.

Excessive skid shoe wear

Cutting height not level.

Adjust deck height or replace.

Soil abrasive.

Raise cutting height.

Cutting too low.

Raise cutting height.

Excessive vibration

Locked blades.

Inspect and unlock blades.

Blades have unequal weight.

Replace blades as a PAIR.

Blade carrier bent.

Replace blade carrier.

Hitch lugs failing

Tilting hitch plate too far forward.

Do not tilt the hitch plate too far forward.

Do not put down pressure on hitch plate