40

TIRES, WHEELS AND BALLAST

TIRES, WHEELS AND BALLAST

TIRES

To avoid personal injury:

A

Do not attempt to mount a tire on a rim. This

should be done by a qualified person with the

proper equipment.

A

Always maintain the correct tire pressure.

Do not inflate tires above the recommended

pressure shown in the operator's manual.

A

Do not use tires other than those approved by

KUBOTA.

B

Inflation Pressure

Though the tire pressure is factory-set to the prescribed

level, it naturally drops slowly over the course of time.

Thus, check it regularly and inflate as necessary.

A

Maintain the maximum recommended pressure in the

front tires, when using a front loader or equipped with

a full load of front weights.

B

Dual Tires

Dual tires are not approved.

WHEEL ADJUSTMENT

To avoid personal injury:

A

When working on slopes or when working with

trailer, set the wheel tread as wide as practical

for maximum stability.

A

Support tractor securely on stands before

removing a wheel.

A

Do not work under any hydraulically supported

devices. They can settle, suddenly leak down,

or be accidentally lowered. If necessary to work

under tractor or any machine elements for

servicing or adjustment, securely support them

with stands or suitable blocking beforehand.

A

Never operate tractor with a loose rim, wheel,

or axle.

B

Front Wheels

Front tread width can not be adjusted.

A

Do not turn front discs to obtain wider tread.

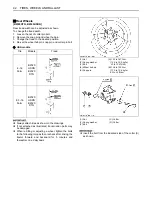

Tire sizes

Inflation Pressure

Rear

8 - 16, 4PR

8.3 - 16, 6PR

9.5 - 16, 4PR

9.5 - 18, 4PR

315/75D - 15, 4PR

11.2 - 16, 4PR

12 - 16.5, 4PR

31x13.5 - 15, 4PR

31x15.5 - 15, 4PR

33x12.5 - 15, 4PR

160kPa(1.6kgf/cm , 23psi)

150kPa(1.5kgf/cm , 22psi)

140kPa(1.4kgf/cm , 20psi)

160kPa(1.6kgf/cm , 23psi)

100kPa(1.0kgf/cm , 14psi)

130kPa(1.3kgf/cm , 18psi)

270kPa(2.7kgf/cm , 40psi)

140kPa(1.4kgf/cm , 20psi)

140kPa(1.4kgf/cm , 20psi)

140kPa(1.4kgf/cm , 20psi)

Front

5 - 12, 4PR

6 - 12, 4PR

7 - 12, 4PR

21x8.00 - 10, 4PR

22x8.50 - 12, 4PR

23x8.50 - 12Turf, 4PR

23x8.50 - 12Ind., 4PR

24x8.50 - 12, 4PR

240kPa(2.4kgf/cm , 34psi)

200kPa(2.0kgf/cm , 28psi)

170kPa(1.7kgf/cm , 24psi)

160kPa(1.6kgf/cm , 23psi)

160kPa(1.6kgf/cm , 23psi)

150kPa(1.5kgf/cm , 22psi)

250kPa(2.5kgf/cm , 35psi)

160kPa(1.6kgf/cm , 23psi)

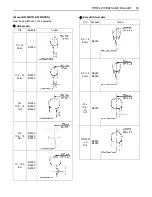

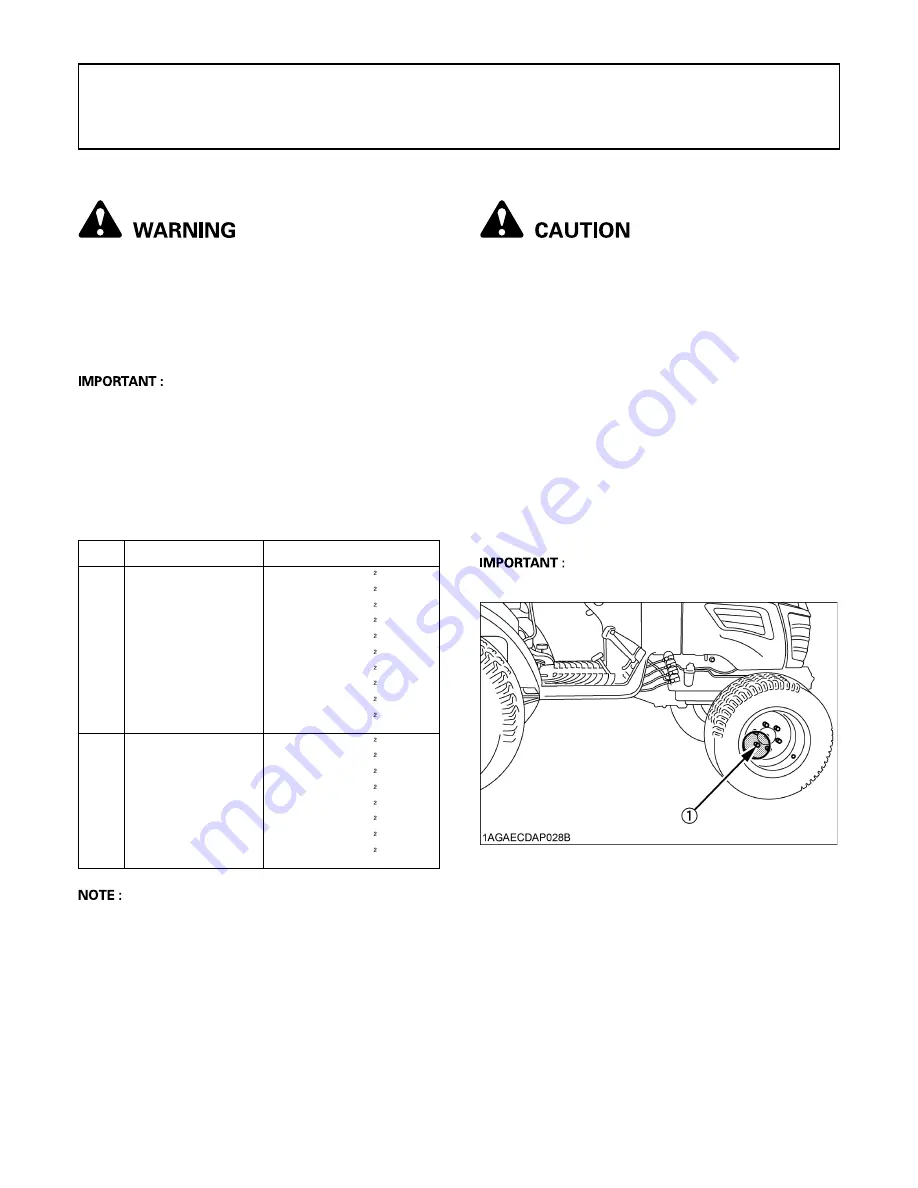

(1) 79 to 92 N-m (8.1 to 9.4 kgf-m, 58.3 to 67.9 ft-lbs)

Summary of Contents for B2320

Page 1: ......

Page 14: ...SAFE OPERATION 6 7 DANGER WARNING AND CAUTION LABELS ...

Page 15: ...7 SAFE OPERATION ...