EVERY 4 YEARS

1. Replacing the radiator hose (water

pipes)

1. Replace the hoses and clamps.

(See Checking radiator hoses and clamps on page

80)

2. Replacing fuel hose

Consult your local KUBOTA Dealer for this service.

3. Replacing the intake air line

Consult your local KUBOTA Dealer for this service.

SERVICE AS REQUIRED

1. Bleeding fuel system

Air must be removed:

• When the fuel filter or lines are removed.

• When tank is completely empty.

• After the tractor has not been used for a long period

of time.

Bleeding procedure is as follows:

1. Fill the fuel tank with fuel.

2. Start the engine and run for about 30 seconds, and

then stop the engine.

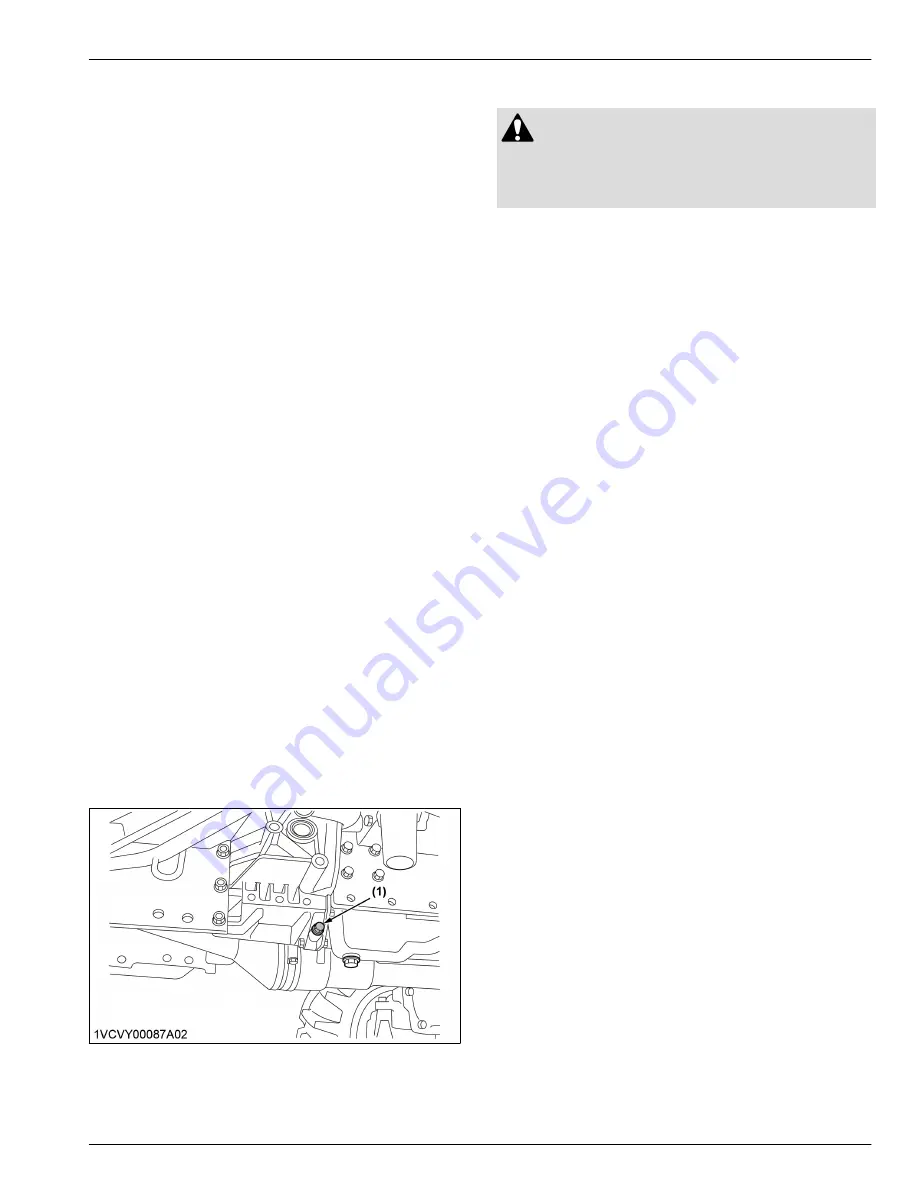

2. Draining clutch housing water

The tractor is equipped with a drain plug under the

clutch housing.

After operating in rain, snow or tractor has been

washed, water may get into the clutch housing.

1. Remove the drain plug and drain the water, then

install the plug again.

(1) Water drain plug

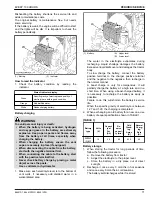

3. Replacing fuse

WARNING

To avoid personal injury or death:

• Do not use a larger than recommended fuse or

bypass the fuse system.

The tractor electrical system is protected from potential

damage by fuses.

A blown fuse indicates that there is an overload or short

somewhere in the electrical system.

EVERY 4 YEARS

PERIODIC SERVICE

B2401DT, B2401DTWO, B2401DTN

81

Summary of Contents for B2401DT

Page 6: ......

Page 17: ...SAFETY LABELS SAFE OPERATION B2401DT B2401DTWO B2401DTN 11...

Page 18: ...SAFE OPERATION 12 B2401DT B2401DTWO B2401DTN...

Page 19: ...SAFE OPERATION B2401DT B2401DTWO B2401DTN 13...

Page 20: ...SAFE OPERATION 14 B2401DT B2401DTWO B2401DTN...