17

MAINTENANCE

ENGLISH

MAINTENANCE

SERVICE INTERVALS

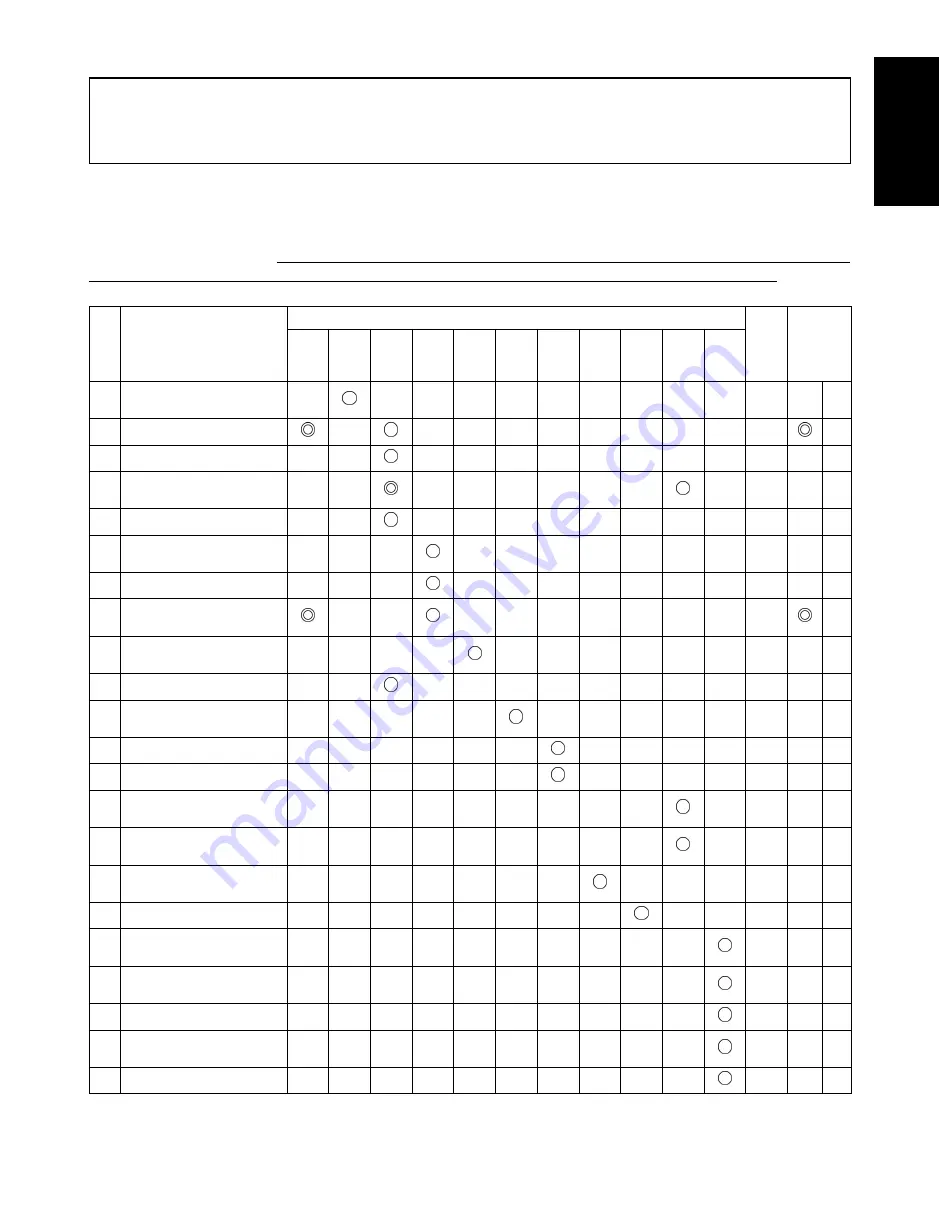

Observe the following for service and maintenance.

The lubricating oil change intervals listed in the table below are for Class CF or better lubricating oil of API classification

with a low-sulfur fuel in use. If the CF-4, CG-4, CH-4 or CI-4 lubricating oil is used with a high-sulfur fuel, change the

lubricating oil at shorter intervals than recommended in the table below depending on the operating condition.

No

Check point

lnterval

Ref

page

First

50

hours

Every

50

hours

Every

100

hours

Every

200

hours

Every

400

hours

Every

500

hours

Every

800

hours

Every

1500

hours

Every

3000

hours

Every

1

year

Every

2

years

1

Check of fuel pipes and clamp

bands

@

2

Change of engine oil

3

Cleaning of air cleaner element

*1

@

4

Check of battery electrolyte

level

5

Check of fan belt tension

6

Check of radiator hoses and

clamp bands

7

Check of intake air hose

-

@

8

Replacement of oil filter

cartridge

9

Replacement of fuel filter

cartridge or element

-

@

10

Cleaning of fuel filter

11

Cleaning of water jacket

(radiator interior)

12

Replacement of fan belt

13

Check of valve clearance

-

14

Replacement of air cleaner

element

*2

@

15

Check of damage in electric

wiring and loose connections

16

Check of fuel injection nozzle

injection pressure

-

*3

@

17

Check of injection pump

-

*3

@

18

Replacement of fuel pipes, fuel

gauge and clamp bands

*3

@

19

Replacement of radiator hoses

and clamp bands

20

Replacement of battery

21

Change of radiator coolant

(L.L.C.)

22

Replacement of intake air hose

-

*4

@

Summary of Contents for GL11000-CAN

Page 2: ...GL 7000 CAN GL 11000 CAN AX L 14 20 1 AK ...

Page 15: ...SAFE OPERATION 8 ENGLISH ...

Page 17: ......

Page 54: ...37 WIRING DIAGRAM ENGLISH WIRING DIAGRAM ...

Page 55: ...WIRING DIAGRAM 38 ENGLISH ...