PERIODIC SERVICE

44

ENGLISH

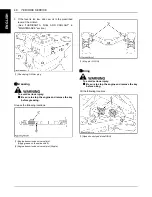

B

Checking Transmission Fluid Level

1. Park the machine on a flat surface, lower the

implement to the ground, shut off engine and remove

the key.

2. Raise the operator's seat.

3. To check the oil level, draw out the dipstick, wipe it

clean, replace it, and draw it out again. Check to see

that the oil level lies between the 2 notches.

If the level is too low, add new oil to the prescribed

level at the oil inlet.

(See "LUBRICANTS, FUEL AND COOLANT" in

"MAINTENANCE" section.)

A

If oil level is low, do not run the engine.

B

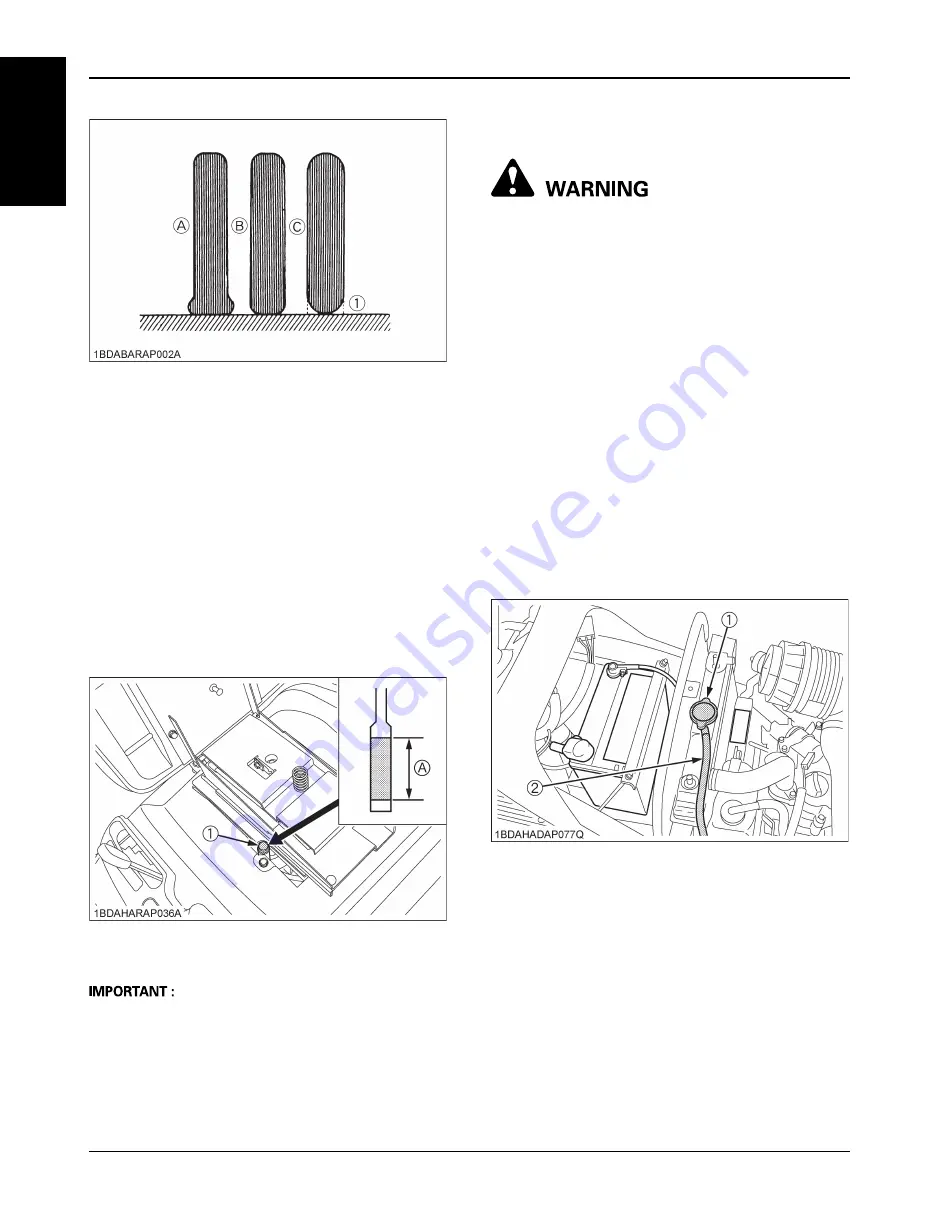

Checking Coolant Level

To avoid serious injury:

A

Be sure to stop the engine and remove the key

before checking coolant level.

A

Do not remove the radiator cap while coolant is

hot. When cool, slowly rotate cap to the first

stop and allow sufficient time for excess

pressure to escape before removing the cap

completely.

Check the coolant level daily both the radiator and the

recovery tank before starting engine.

1. Remove the radiator cap and check to see that the

coolant level is just below the fill port.

2. Check to see that the coolant level is between the

"FULL" and "LOW" marks of recovery tank.

3. When the coolant level drops due to evaporation, add

water only up to just below the fill port of the radiator

and the full level of the recovery tank.

In case of leakage, add anti-freeze and water in the

specified mixing ratio up to the full level.

(See "Flush Cooling System and Changing Coolant" in

"EVERY 2000 HOURS or EVERY 2 YEARS" in

"PERIODIC SERVICE" section.)

(1) Ground

(A) "INSUFFICIENT"

(B) "NORMAL"

(C) "EXCESSIVE"

(1) Oil level dipstick

(A) Oil level is acceptable

within this range.

(1) Radiator cap

(2) Over flow pipe