OPERATING THE GRASS CATCHER

34

ENGLISH

B

Replacing

1. Remove handles, flange nuts and black flange bolts

from the top of the grass container cover.

2. Remove the plastic cover from the container.

3. Remove square neck bolts and nuts to remove the

bottom plate.

4. Then remove the container net from the frame.

5. To attach new or cleaned net, reverse the above

procedures and be sure to install removed

components.

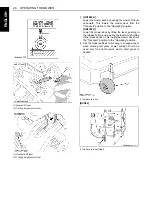

(1) Handle

(2) Flange nut

(3) Black flange bolt

(4) Cover

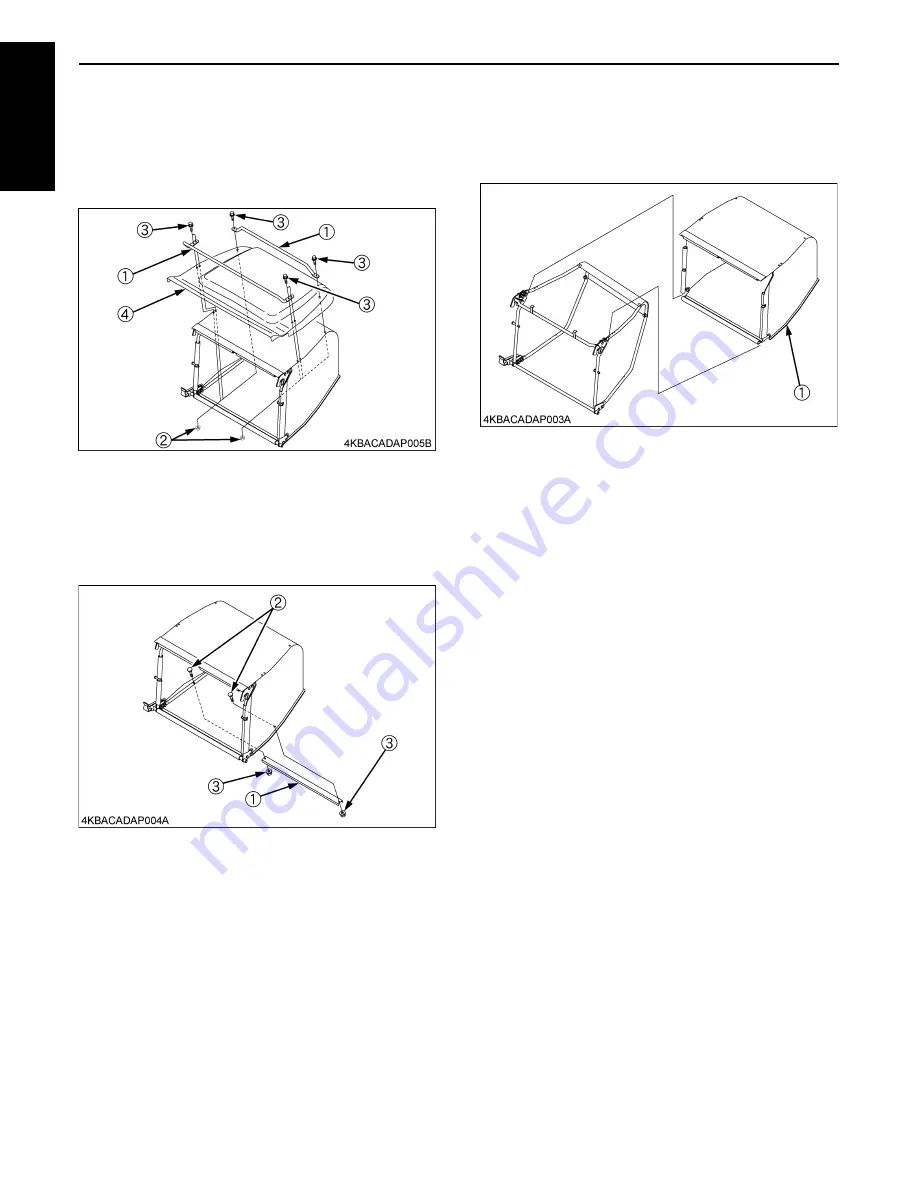

(1) Bottom plate

(2) Square neck bolt

(3) Flange nut

(1) New or cleaned net

Summary of Contents for GR1600-II

Page 2: ...ENGLISH MODELS GR1600 II GR2100 II OPERATOR S MANUAL RIDING MOWER 1BDAHAGAP0360 ...

Page 5: ...FRANÇAIS MODELES GR1600 II GR2100 II TONDEUSE AUTOPORTEE 1BDAHAGAP0360 ...

Page 8: ...DEUTSCH MODELLE GR1600 II GR2100 II AUFSITZMAHER 1BDAHAGAP0360 ...

Page 12: ......

Page 13: ......

Page 24: ...7 SAFE OPERATION ENGLISH 8 DANGER WARNING AND CAUTION LABELS ...

Page 25: ...SAFE OPERATION 8 ENGLISH ...

Page 26: ...9 SAFE OPERATION ENGLISH ...