31

MAINTENANCE

ENGLISH

EVERY 500 HOURS

Replacing Oil Filter Cartridge

1.

Replace the oil filter cartridge every 500 hours of

use. (Every second oil change.)

2.

Coat the new filter gasket lightly with clean oil.

3.

Tighten it securely by hand.

4.

When the filter is replaced, the engine oil level will

drop. Run the engine for a few minutes, and check

for oil leaks. Re-check the oil level. If the oil level is

too low, add engine oil up to the specified level.

z

zz

z

z

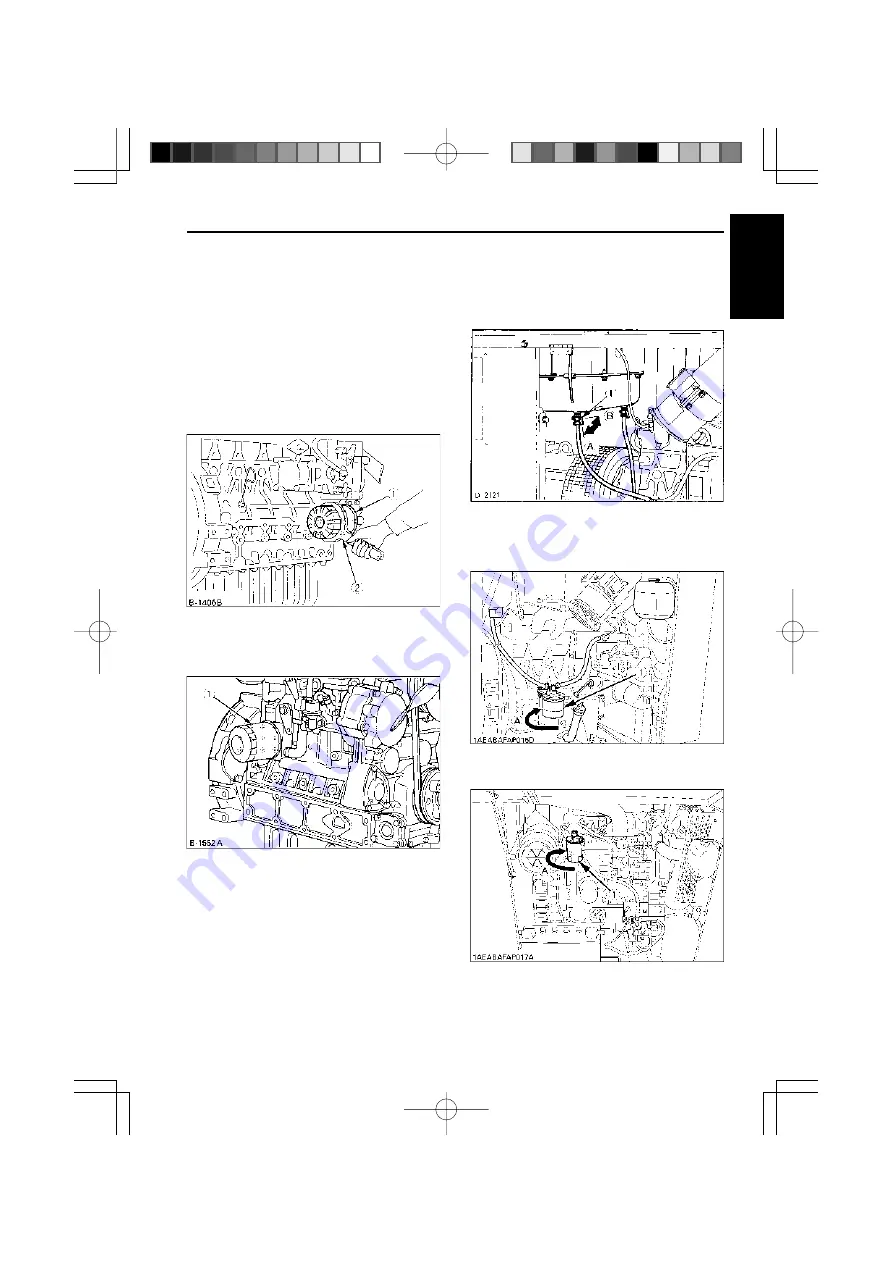

Engine model : D1703-EBG, V2203-EBG

x

xx

x

x

(1) Oil filter cartridge

(2) Remove with a filter wrench

(Tighten with your hand)

z

zz

z

z

Engine model : V3300-EBG

x

xx

x

x

(1) Oil filter cartridge

Replacing Fuel Filter Cartridge

Replace the fuel filter cartridge every 500 hours of

use, using the following procedure.

1.

Close the fuel tank tap.

(1) Fuel tank tap

(A) “OPEN”

(B) “CLOSE”

2.

Remove the fuel filter by using ring spanner.

z

zz

z

z

Engine model : D1703-EBG, V2203-EBG

x

xx

x

x

(1) Fuel filter cartridge

(A) “REMOVE”

z

zz

z

z

Engine model : V3300-EBG

x

xx

x

x

(1) Fuel filter cartridge

(A) “REMOVE”

3.

Tighten it securely by hand.

Summary of Contents for KJ-S130VX

Page 1: ...G3601 8911 8 ...

Page 55: ...39 ENGLISH TROUBLESHOOTING 쎱 When Engine must be Stopped Immediately 쎱 When Engine Overheats ...

Page 56: ...40 ENGLISH TROUBLESHOOTING ...

Page 57: ...41 ENGLISH WIRING DIAGRAM Engine Circuit Diagram for D1703 V2203 ...

Page 58: ...42 ENGLISH WIRING DIAGRAM Engine Circuit Diagram for V3300 ...

Page 63: ...47 ENGLISH WIRING DIAGRAM Generator Circuit Diagram KJ S130VX AUS 240V 50Hz ...

Page 65: ...49 ENGLISH WIRING DIAGRAM Generator Circuit Diagram KJ S240 AUS 240V 50Hz ...

Page 66: ...50 ENGLISH WIRING DIAGRAM Generator Circuit Diagram KJ T300 AUS 415 240V 50Hz ...