-

1

SAFE OPERATION

SAFE OPERATION

Careful operation is your best insurance against an

accident.

Read and understand this manual carefully, before

operating the excavator.

Every user, however experienced, should carefully read

and understand this manual and those of the attachments

and accessories before operating the excavator. The

owner is obliged to inform all operators of these

instructions in detail.

Keep this manual in the storage location. (See "Where to

keep Operator's Manual" in "MAINTENANCE" section.)

1. Know your equipment and its limitations. Read and

understand this entire manual before attempting to

start and operate the excavator.

2. Obey the danger, warning and caution labels on the

machine.

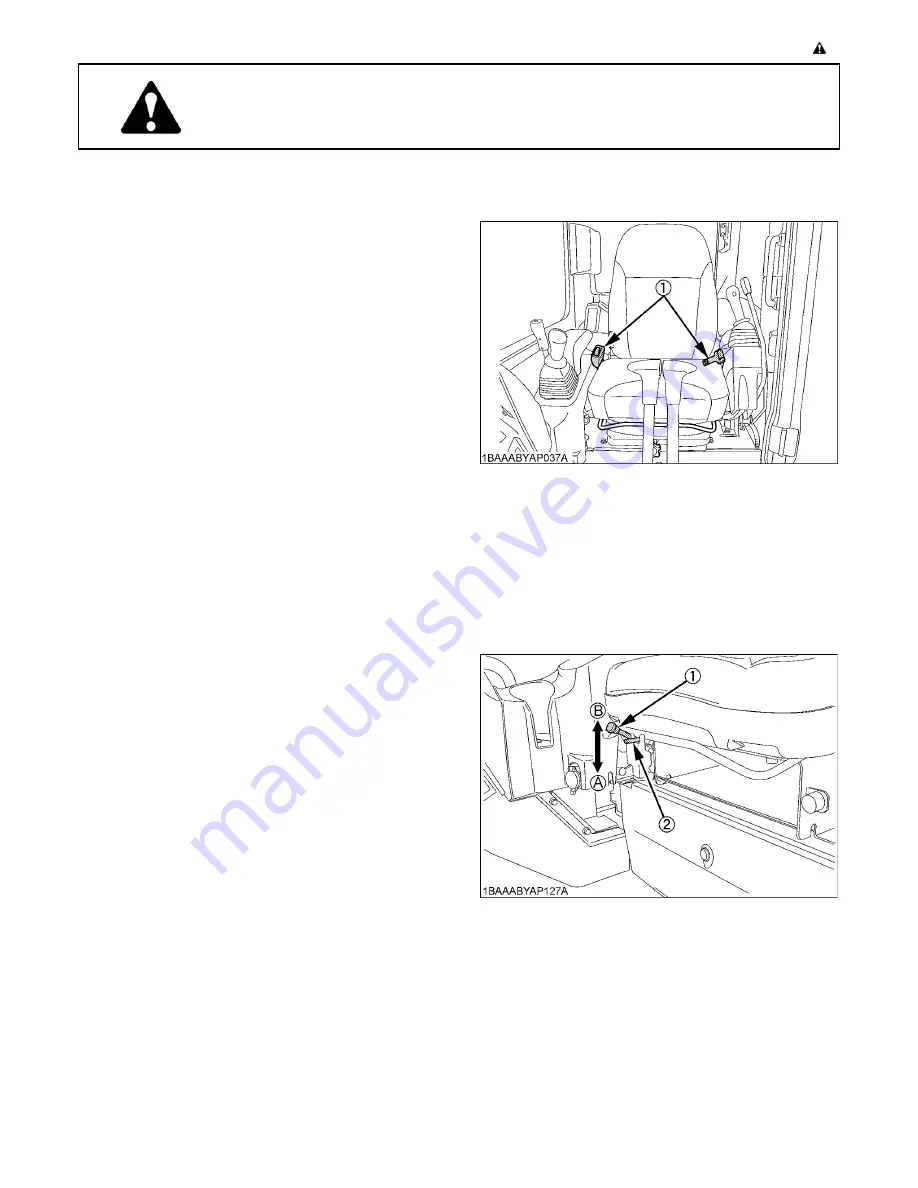

3. For your safety, a ROPS/FOPS (Roll-Over Protective

Structure, Falling Objects Protective Structure.) with a

seat belt is installed by KUBOTA. Always use the seat

belt when the machine is equipped with a ROPS/

FOPS as this combination will reduce the risk of

serious injury or death, should the excavator be upset

or falling objects occur.

Do not modify any structural members of the ROPS/

FOPS by welding, drilling, bending, grinding or cutting,

as this may weaken the structure. If any component is

damaged, replace it. Do not attempt repairs. If the

ROPS/FOPS is loosened or removed for any reason,

make sure all parts are reinstalled correctly. Tighten

mounting bolts to proper torque.

4. ROPS/FOPS structure complies with ISO 3471, ISO

3449 and OSHA regulations.

5. The seat belt must be inspected regularly and

replaced if frayed or damaged.

6. Always sit in the operator's seat when starting engine

or operating levers or controls.

7. Study control lever pattern A and pattern B. Then

choose the one which is most familiar.

Familiarize yourself with the pattern selected by

operating the unit slowly and at low engine speed.

A

Engage the lever lock to prevent accidental pattern

change.

8. Do not operate the excavator while under the influence

of alcohol, medication, controlled substances or while

fatigued.

1.

BEFORE OPERATION

(1) Seat belt

(1) Pattern selector lever

(Two Pattern Selection System:TPSS)

(2) Lever lock

(A) "Pattern A"

(B) "Pattern B"

Summary of Contents for KX040-4

Page 10: ......

Page 18: ...SAFE OPERATION 8 6 DANGER WARNING AND CAUTION LABELS...

Page 19: ...9 SAFE OPERATION...

Page 20: ...SAFE OPERATION 10...

Page 21: ...11 SAFE OPERATION...

Page 22: ...SAFE OPERATION 12...

Page 23: ...13 SAFE OPERATION...

Page 69: ...45 EXCAVATOR OPERATION...

Page 125: ...101 LIFTING CAPACITY...

Page 126: ...102 LIFTING CAPACITY...