21

CHECKS BEFORE START

B

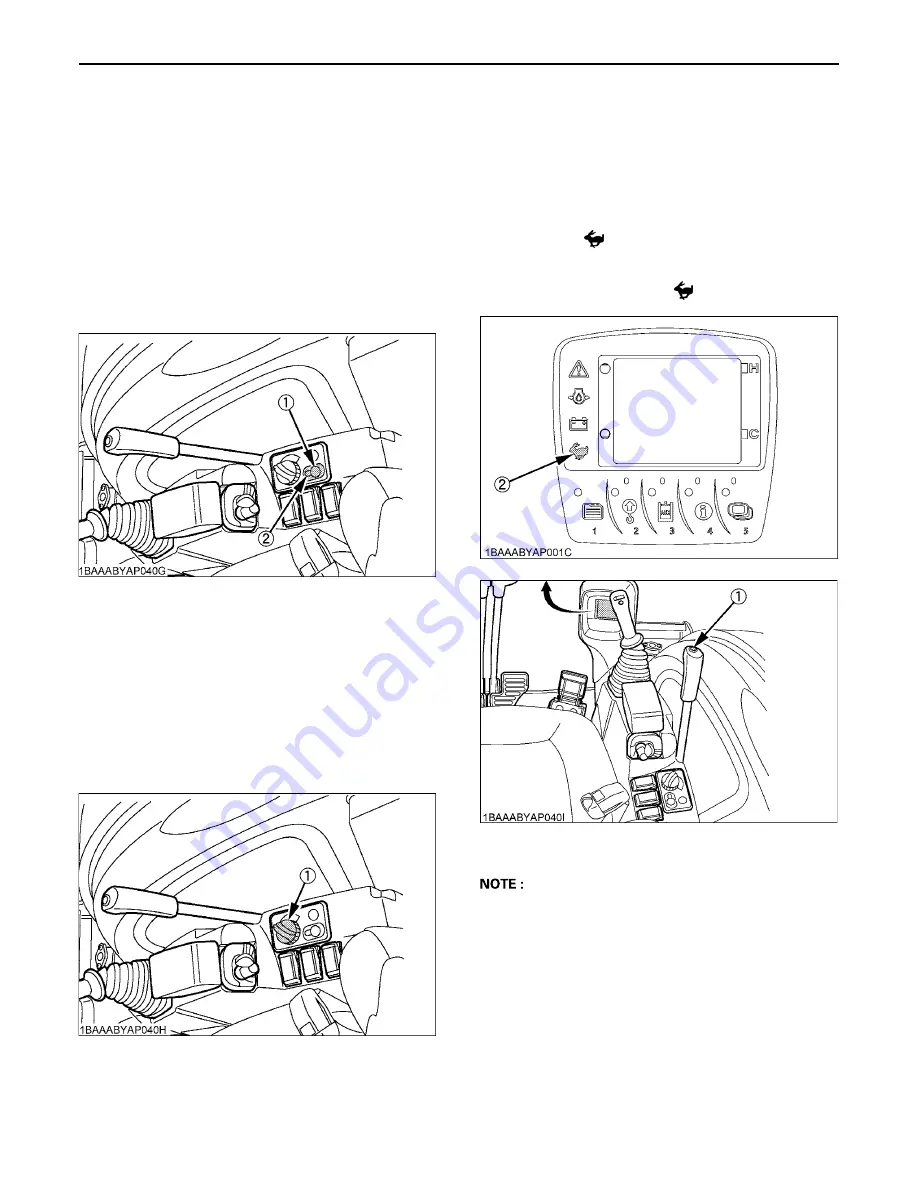

Auto Idle Switch

The switch is used to enable and disable the Auto Idle

control.

B

Throttle Potentiometer

1. Sit down on the operator's seat and turn the throttle

potentiometer clockwise (toward the high speed), and

the engine revs up.

2. To stop the engine, turn the throttle potentiometer fully

toward the low speed and keep the engine at the idling

speed. Then set the starter key to the

"STOP"

position.

B

Travel Speed Switch

Travel speed will increase when this switch is pushed

down.

Switching the dual travel speed:

1. Press the travel speed switch. The buzzer beeps twice

and the travel speed changes from first speed to

second. The

symbol lights up.

2. Press the travel speed switch again, and the buzzer

beeps once and the travel speed changes from

second speed to first. The

symbol goes out.

A

When activating the travel speed switch, it must be

pushed down completely.

A

Each time the travel speed switch is pressed, the

travel speed is switched between first and second.

A

Enable:

Press the Auto Idle switch. When the

Auto Idle control is on, the Auto Idle lamp

stays on.

A

Disable:

Press the Auto Idle switch once again.

Now the Auto Idle control is deactivated

(The Auto Idle lamp goes out.)

(1) Auto idle switch

(2) Auto idle lamp

(1) Throttle potentiometer

(1) Travel speed switch

(2) Speed indicator light

Summary of Contents for KX057-4

Page 1: ......

Page 15: ...7 SAFE OPERATION 6 DANGER WARNING AND CAUTION LABELS...

Page 16: ...SAFE OPERATION 8...

Page 17: ...9 SAFE OPERATION...

Page 18: ...SAFE OPERATION 10...

Page 19: ...11 SAFE OPERATION...

Page 20: ...SAFE OPERATION 12...

Page 22: ......

Page 74: ...52 EXCAVATOR OPERATION...

Page 122: ...100 LIFTING CAPACITY...

Page 123: ...101 LIFTING CAPACITY...

Page 124: ...102 LIFTING CAPACITY...

Page 125: ...103 LIFTING CAPACITY...

Page 126: ...104 LIFTING CAPACITY...

Page 127: ...105 LIFTING CAPACITY...

Page 128: ...106 LIFTING CAPACITY...

Page 129: ...107 LIFTING CAPACITY...