61

REGULAR CHECKS AND MAINTENANCE WORK

B

Battery Charging

To avoid personal injury:

A

When the battery is being activated, hydrogen

and oxygen gases in the battery are extremely

explosive. Keep open sparks and flames away

from the battery at all times, especially when

charging the battery.

A

When charging battery, remove battery vent

plugs.

A

When disconnecting the cable from the battery,

start with the negative terminal first.

When connecting the cable to the battery, start

with the positive terminal first.

A

Do not check battery charge by placing a metal

object across the terminals.

Use a voltmeter or hydrometer.

1. Make sure each electrolyte level is to the bottom of

vent wells. If necessary add distilled water in a well-

ventilated area.

2. The water in the electrolyte evaporates during

recharging. Liquid shortage damages the battery.

Excessive liquid spill damages the excavator body.

3. To slowly charge the battery, connect the battery

positive terminal to the charger’s positive terminal and

the negative to the negative one. Then, recharge in the

standard fashion.

4. A boost charge is only for emergencies. It will partially

charge the battery at a high rate and in a short time.

When using a boost-charged battery, it is necessary to

recharge the battery as early as possible.

Failure to do this will shorten the battery's service life.

5. When the specific gravity of electrolyte falls between

1.27 and 1.29, charge has completed.

6. When exchanging old battery for a new one, use

battery of equal specification.

B

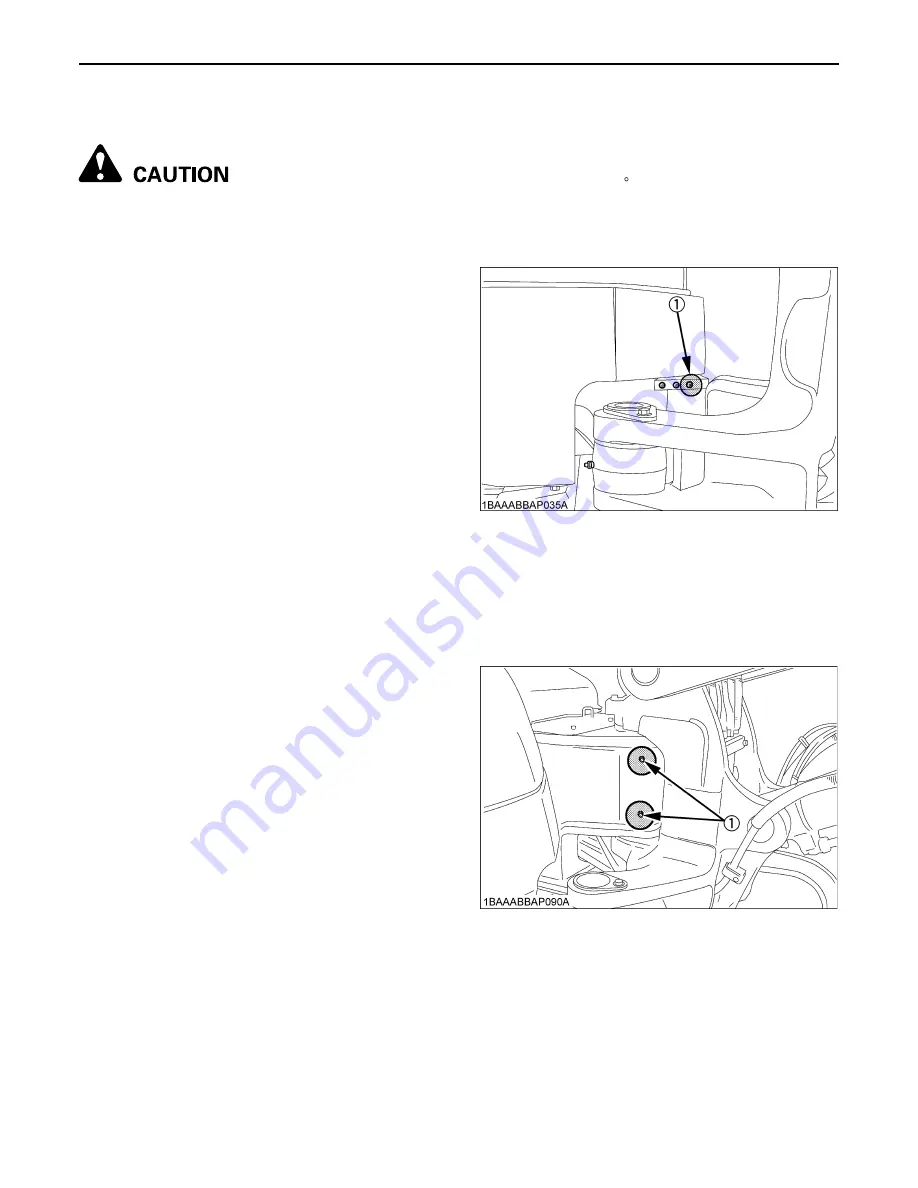

Greasing Swing Bearing Teeth

1. Pump grease with the grease gun through the grease

nipple.

2. Grease at each 90 (1.58 rad.) position of the swing

frame.

3. Fill with approx. 50g of grease (approx. 20 to 30

pumps with the grease gun at each position).

Distribute the grease over the teeth.

EVERY 100 SERVICE HOURS

B

Greasing Boom Swing Fulcrum

Grease the marked grease nipples shown by arrows in the

illustration below.

(1) Grease nipple (for swing bearing teeth)

(1) Boom swing fulcrum

Summary of Contents for KX080-3

Page 15: ...7 SAFE OPERATION...

Page 16: ...SAFE OPERATION 8...

Page 17: ...9 SAFE OPERATION...

Page 18: ...SAFE OPERATION 10...

Page 19: ...11 SAFE OPERATION...

Page 20: ...SAFE OPERATION 12...

Page 22: ......

Page 115: ...93 LIFTING CAPACITY...