REGULAR CHECKS AND MAINTENANCE WORK

72

B

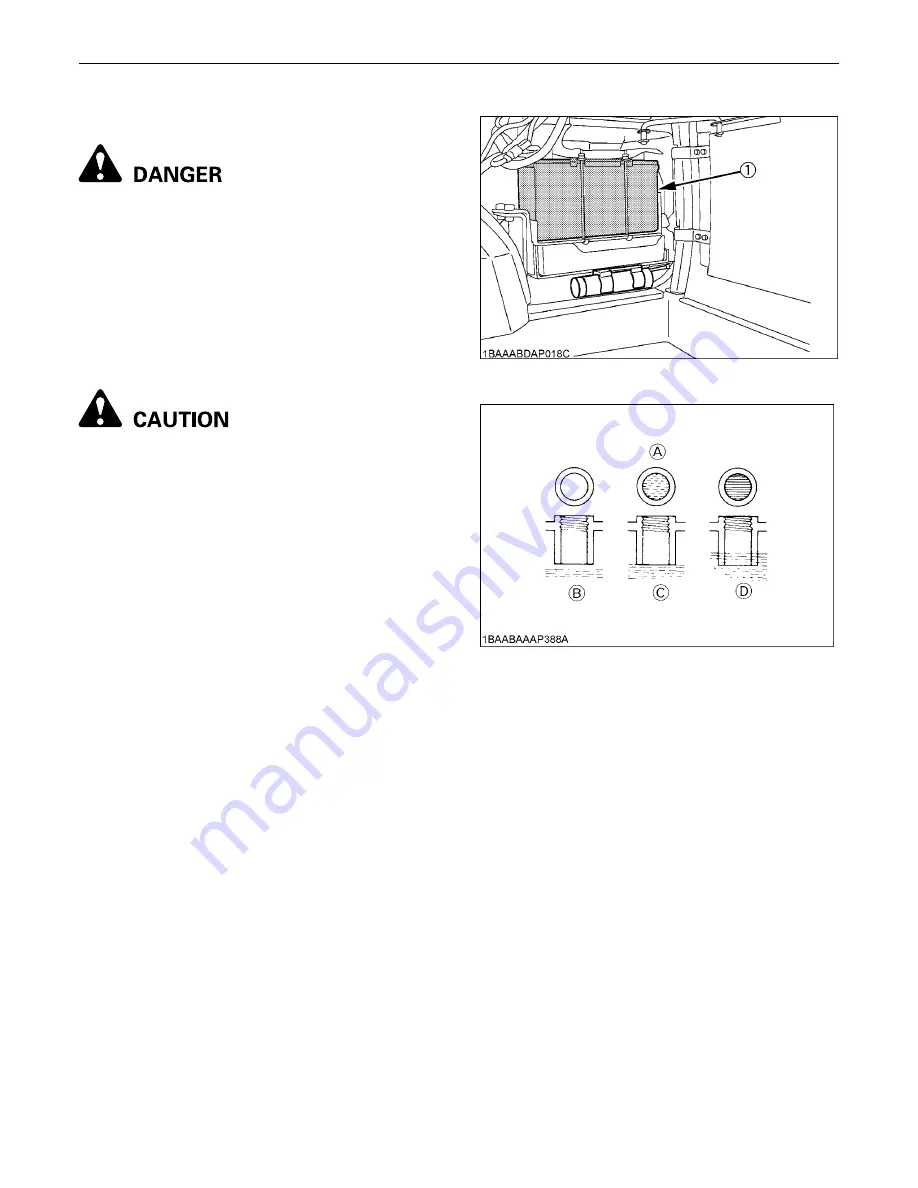

Battery

To avoid the possibility of a battery explosion:

For refillable type battery, follow the instructions

below.

A

Do not use or charge the refillable type battery

if the fluid level is below the LOWER (lower limit

level) mark. Otherwise, the battery component

parts may prematurely deteriorate, which may

shorten the battery's service life or cause an

explosion. Check the fluid level regularly and

add distilled water as required so that the fluid

level is between the UPPER and LOWER levels.

To avoid personal injury:

A

Never remove the vent caps while the engine is

running.

A

Keep electrolyte away from eyes, hands and

clothes. If you are spattered with it, wash it

away completely with water immediately and

get medical attention.

A

Wear eye protection and rubber gloves when

working around the battery.

A

Before inspection or dismounting the battery,

be sure to turn off the engine and turn the

starter switch to the "OFF" position.

A

When removing the battery, always disconnect

the negative ground cable first. When installing

a battery, always connect the ground cable

last. This prevents a possible explosion caused

by sparks.

A

Always wear eye protection when working with

the battery.

1. Open the side cover. (See "Opening / Closing of the

Side Cover in "MAINTENANCE" section.)

2. Check the battery fluid level and add distilled water if

necessary.

3. Should battery fluid be spilled, fill with sulphuric acid

solution of the same concentration.

4. Clean the battery caps (ventilation holes).

(1) Battery

(A) Battery fluid level

(B) "Too low"

(C) "Correct"

(D) "Too high"

Summary of Contents for KX080-4

Page 10: ......

Page 18: ...SAFE OPERATION 8...

Page 19: ...9 SAFE OPERATION...

Page 20: ...SAFE OPERATION 10...

Page 21: ...11 SAFE OPERATION...

Page 22: ...SAFE OPERATION 12...

Page 23: ...13 SAFE OPERATION...

Page 70: ...46 EXCAVATOR OPERATION...

Page 127: ...103 LIFTING CAPACITY...