CHECKS BEFORE START

24

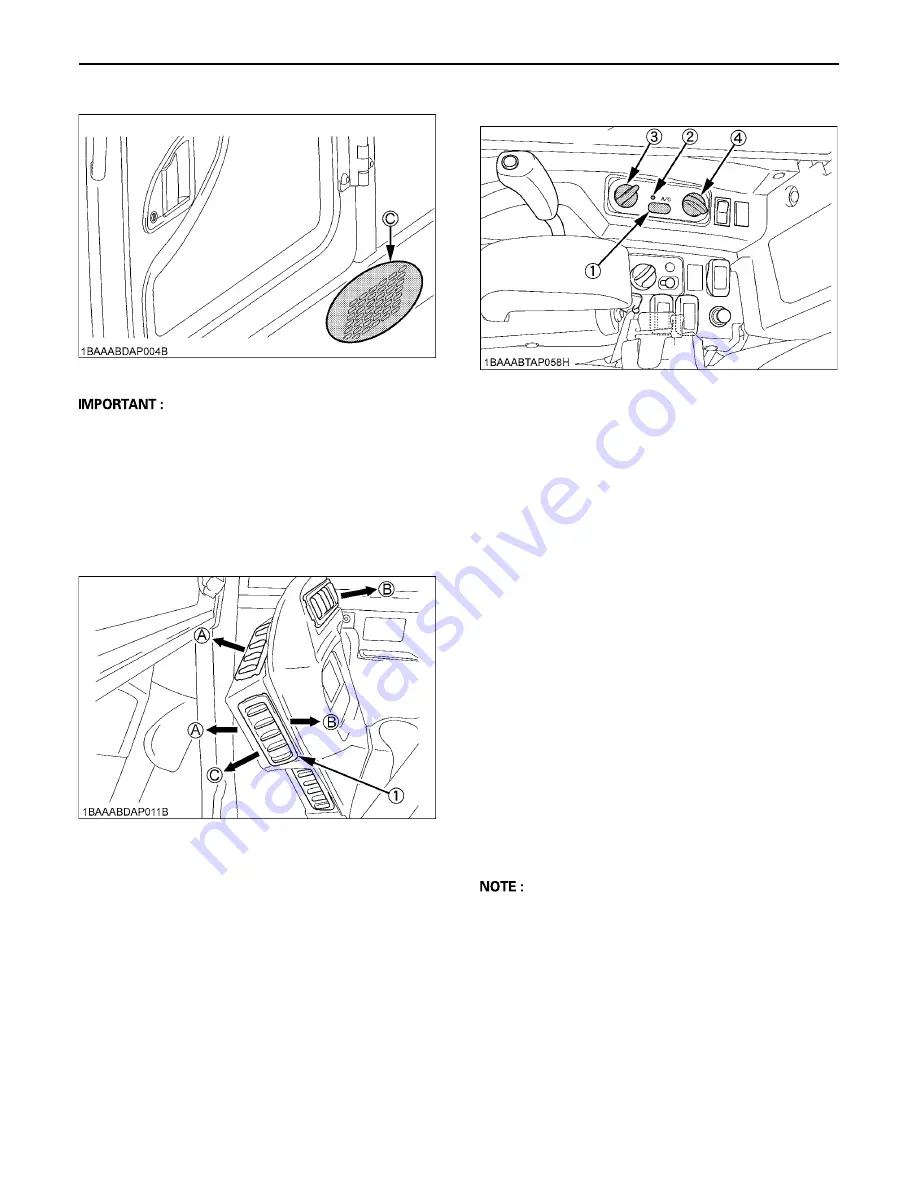

A

Do not allow water to enter the fresh air port while

washing the excavator.

B

Air Control Vent

C

Front air outlet

The front air outlets can be independently adjusted as

required. To defrost the windshield, rotate the outlets

toward the windshield.

B

Control Panel

C

Air Conditioner Switch and Indicator Light

Push this switch to activate the air conditioner. An

indicator light will light up when the switch is set to "ON".

Push switch again to turn air conditioner off, the indicator

light will go off.

C

Temperature Control Dial

Set this dial at the desired position to obtain the desired

air temperature. Turn the dial to the right to obtain cooler

air. Turn it to the left to obtain warmer air.

C

Blower Switch

Air volume can be changed in three steps. At the "3"

position, the largest air volume is obtained.

B

Operation

C

Heating

1. Adjust the blower (1/2/3) switch and the temperature

control dial to achieve the desired temperature level.

C

Dehumidifying-heating

1. Press and turn on the air-conditioner switch.

2. Turn on the blower (1/2/3) switch.

3. Adjust the temperature control dial to the "COOL" or

an intermediate position to achieve the desired

temperature level.

A

Be sure to close the door while the air conditioner is

ON otherwise, you may overload the compressor.

C

Cooling

1. Press and turn on the air-conditioner switch.

2. Turn on the blower (1/2/3) switch.

3. Adjust the temperature control dial to the "COOL" or

an intermediate position to achieve the desired

temperature level.

(C) "FRESH AIR INLET"

(1) Front air outlet

(A) "FRONT WINDOW"

(B) "CLOSED"

(C) "FOOT AREA"

(1) Air conditioner switch

(2) Indicator light

(3) Temperature control dial

(4) Blower switch

Summary of Contents for KX080-4S2

Page 10: ......

Page 18: ...SAFE OPERATION 8...

Page 19: ...9 SAFE OPERATION...

Page 20: ...SAFE OPERATION 10...

Page 21: ...11 SAFE OPERATION...

Page 22: ...SAFE OPERATION 12...

Page 23: ...13 SAFE OPERATION...

Page 26: ...DEALER SERVICE 2 1 Engine serial No...

Page 71: ...47 EXCAVATOR OPERATION...

Page 131: ...107 LIFTING CAPACITY...