MAINTENANCE

OM 0341SB74-A

28

AVOIDABLE DAMAGES

POSSIBLE CAUSES

CORRECTIVE ACTIONS

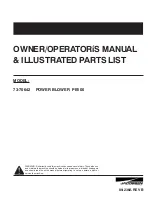

CROSS KIT

•

Cross arms broken.

•

Extreme torque peak or

shock load.

•

Axial loads too high.

•

Use appropriate safety

device.

•

Change to a larger

driveline size.

•

Shorten driveline shaft.

•

Replace defective cross

bearings.

•

Bearing caps turning in

their cross journal.

•

Overheated bearing caps.

•

Excessive continuous

torque and/or excessive

working angle.

•

Inadequate greasing.

•

Verify compatibility

between shaft and working

conditions.

•

Carefully follow greasing

instructions.

•

Replace defective cross

bearings.

•

Accelerated wear of cross

kit.

•

Excessive continuous

torque and/or excessive

working angle.

•

Inadequate greasing.

•

Verify compatibility

between shaft and working

conditions.

•

Carefully follow greasing

instructions.

•

Replace defective cross

bearings.

Note: Cross bearings must be greased every 8 working hours.

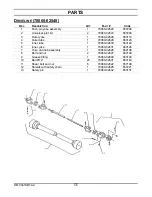

AVOIDABLE DAMAGES

POSSIBLE CAUSES

CORRECTIVE ACTIONS

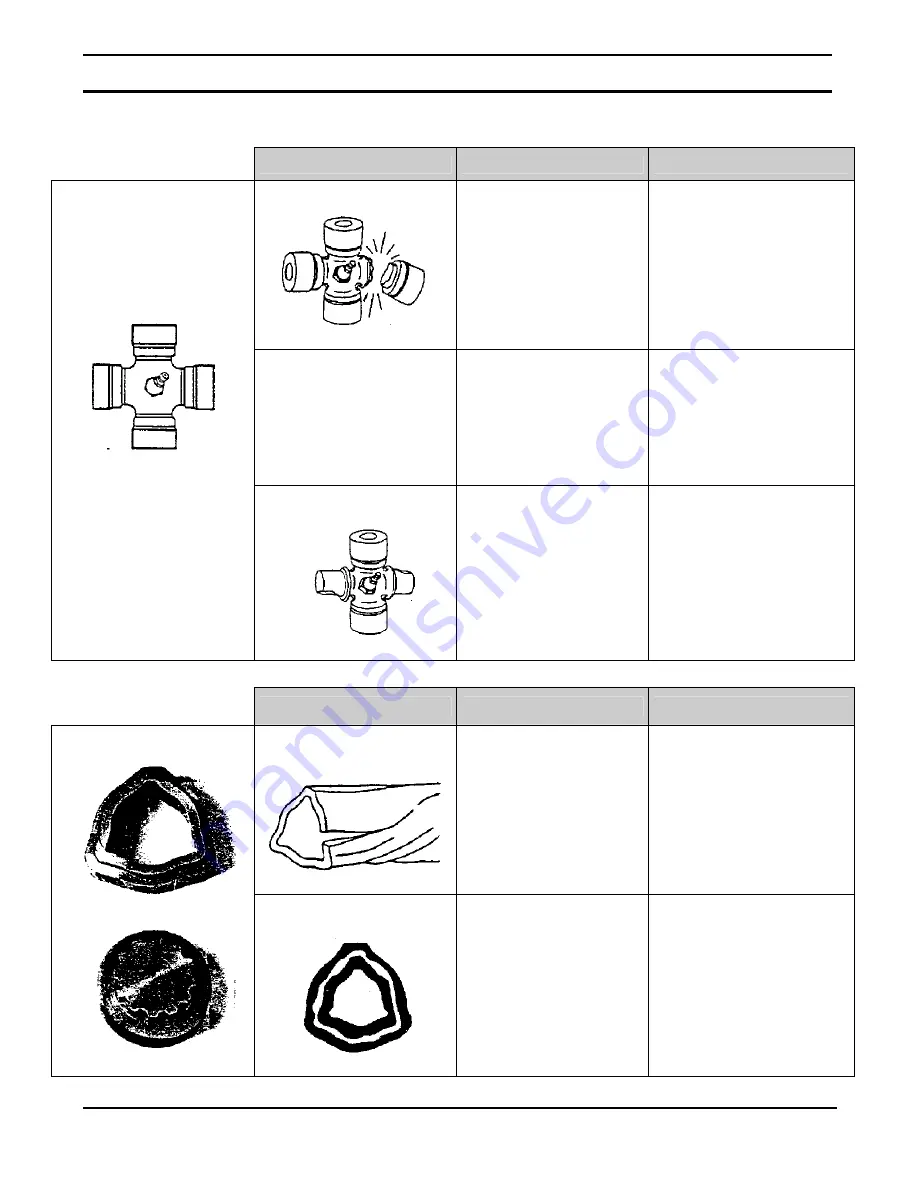

TELESCOPIC TUBES

•

Telescopic tubes failure or

twisting.

•

Extreme torque peak or

shock load.

•

Short tube engagement.

•

Use appropriate safety

device.

•

Change to a larger

driveline size.

•

Replace the driveline drive

shaft with one having

adequate length.

•

Replace defective tubes.

•

Accelerated wear of

telescopic tubes.

•

Extreme load when

sliding.

•

Short tube engagement.

•

Inadequate greasing.

•

Dirt

•

Change to a driveline with

rilsan coated inner tube.

•

Replace the driveline with

one having adequate

length.

•

Carefully follow greasing

instructions.

•

Replace defective tubes.

Note: Telescopic tubes must be cleaned and greased every 8 working hours.

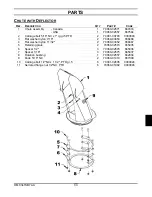

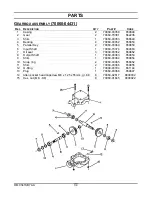

Summary of Contents for L2674

Page 2: ......

Page 4: ......

Page 20: ...ASSEMBLY OM 0341SB74 A 16 Figure 6 Figure 7 Figure 6A ...

Page 35: ...PARTS OM 0341SB74 A 31 SNOWBLOWER ASSEMBLY L2674 ...