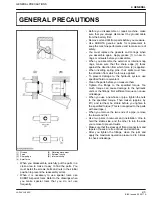

GENERAL PRECAUTIONS

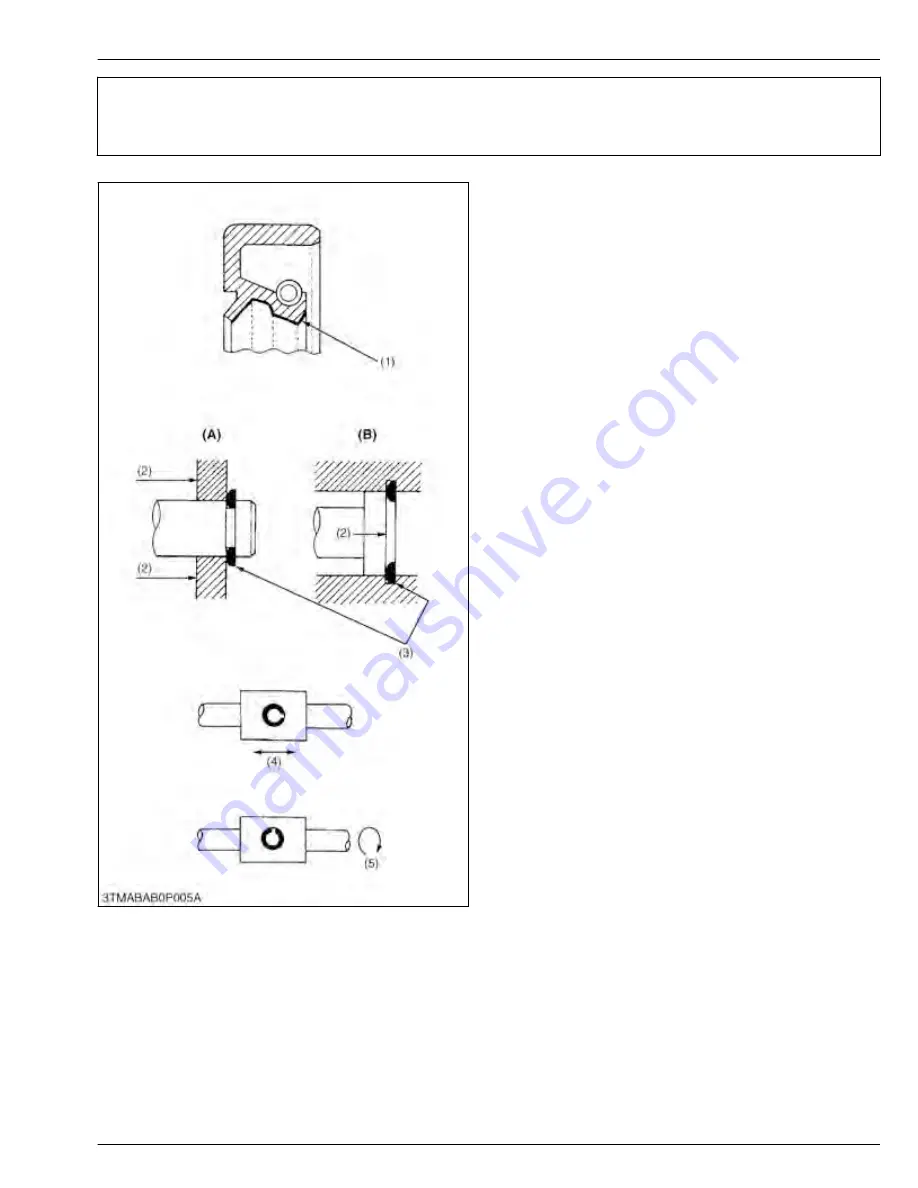

(1) Grease

(2) Force

(3) Sharp edge

(4) Axial force

(5) Rotating movement

(A) External circlip

(B) Internal circlip

• When you disassemble, carefully put the parts in a

clean area to make it easy to find the parts. You

must install the screws, bolts and nuts in their initial

position to prevent the reassembly errors.

• When it is necessary to use special tools, use

KUBOTA special tools. Refer to the drawings when

you make special tools that you do not use

frequently.

• Before you disassemble or repair machine, make

sure that you always disconnect the ground cable

from the battery first.

• Remove oil and dirt from parts before you measure.

• Use KUBOTA genuine parts for replacement to

keep the machine performance and to make sure of

safety.

• You must replace the gaskets and O-rings when

you assemble again. Apply grease (1) to new O-

rings or oil seals before you assemble.

• When you assemble the external or internal snap

rings, make sure that the sharp edge (3) faces

against the direction from which force (2) is applied.

• When inserting spring pins, their splits must face

the direction from which a force is applied.

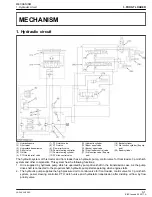

• To prevent damage to the hydraulic system, use

specified fluid or equivalent.

• Clean the parts before you measure them.

• Tighten the fittings to the specified torque. Too

much torque can cause damage to the hydraulic

units or the fittings. Not sufficient torque can cause

oil leakage.

• When you use a new hose or pipe, tighten the nuts

to the specified torque. Then loosen (approx. by

45°) and let them be stable before you tighten to

the specified torque (This is not applied to the parts

with seal tape.).

• When you remove the two ends of a pipe, remove

the lower end first.

• Use two pliers in removal and installation. One to

hold the stable side, and the other to turn the side

you remove to prevent twists.

• Make sure that the sleeves of flared connectors and

tapers of hoses are free of dust and scratches.

• After you tighten the fittings, clean the joint and

apply the maximum operation pressure 2 to 3 times

to check oil leakage.

GENERAL PRECAUTIONS

2. GENERAL

LA344, LA344S

2-3

KiSC issued 02, 2017 A

Summary of Contents for LA344

Page 1: ...LA344 LA344S WORKSHOP MANUAL FRONT LOADER KiSC issued 02 2017 A ...

Page 5: ...1 INFORMATION KiSC issued 02 2017 A ...

Page 9: ...1 INFORMATION SAFETY FIRST 1 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 11: ...1 INFORMATION SAFETY DECALS 1 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 12: ...SAFETY DECALS 1 INFORMATION LA344 LA344S 1 7 KiSC issued 02 2017 A ...

Page 15: ...1 INFORMATION TERMINOLOGY 1 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 20: ...2 GENERAL KiSC issued 02 2017 A ...

Page 22: ...2 GENERAL IDENTIFICATION 2 2 LA344 LA344S KiSC issued 02 2017 A ...

Page 24: ...2 GENERAL 2 4 LA344 LA344S KiSC issued 02 2017 A ...

Page 26: ...2 GENERAL LUBRICATING SYSTEM 2 6 LA344 LA344S KiSC issued 02 2017 A ...

Page 30: ...2 GENERAL TIGHTENING TORQUES 5 Hydraulic fittings 2 10 LA344 LA344S KiSC issued 02 2017 A ...

Page 32: ...2 GENERAL MAINTENANCE CHECK LIST 2 12 LA344 LA344S KiSC issued 02 2017 A ...

Page 36: ...2 GENERAL SPECIAL TOOLS 1 Special tools for loader 2 16 LA344 LA344S KiSC issued 02 2017 A ...

Page 37: ...3 FRONT LOADER KiSC issued 02 2017 A ...

Page 71: ...3 FRONT LOADER SERVICING 5 Servicing 3 34 LA344 LA344S KiSC issued 02 2017 A ...